Thin metal-based diamond cutting slice for cutting semiconductor chip BGA encapsulation body in saw mode and manufacturing method thereof

A technology for cutting chips and packages, which is applied in semiconductor/solid-state device manufacturing, manufacturing tools, stone processing equipment, etc. It can solve the problems of not cutting BGA package chips, lip effect, cutting length difficult to exceed 2km, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

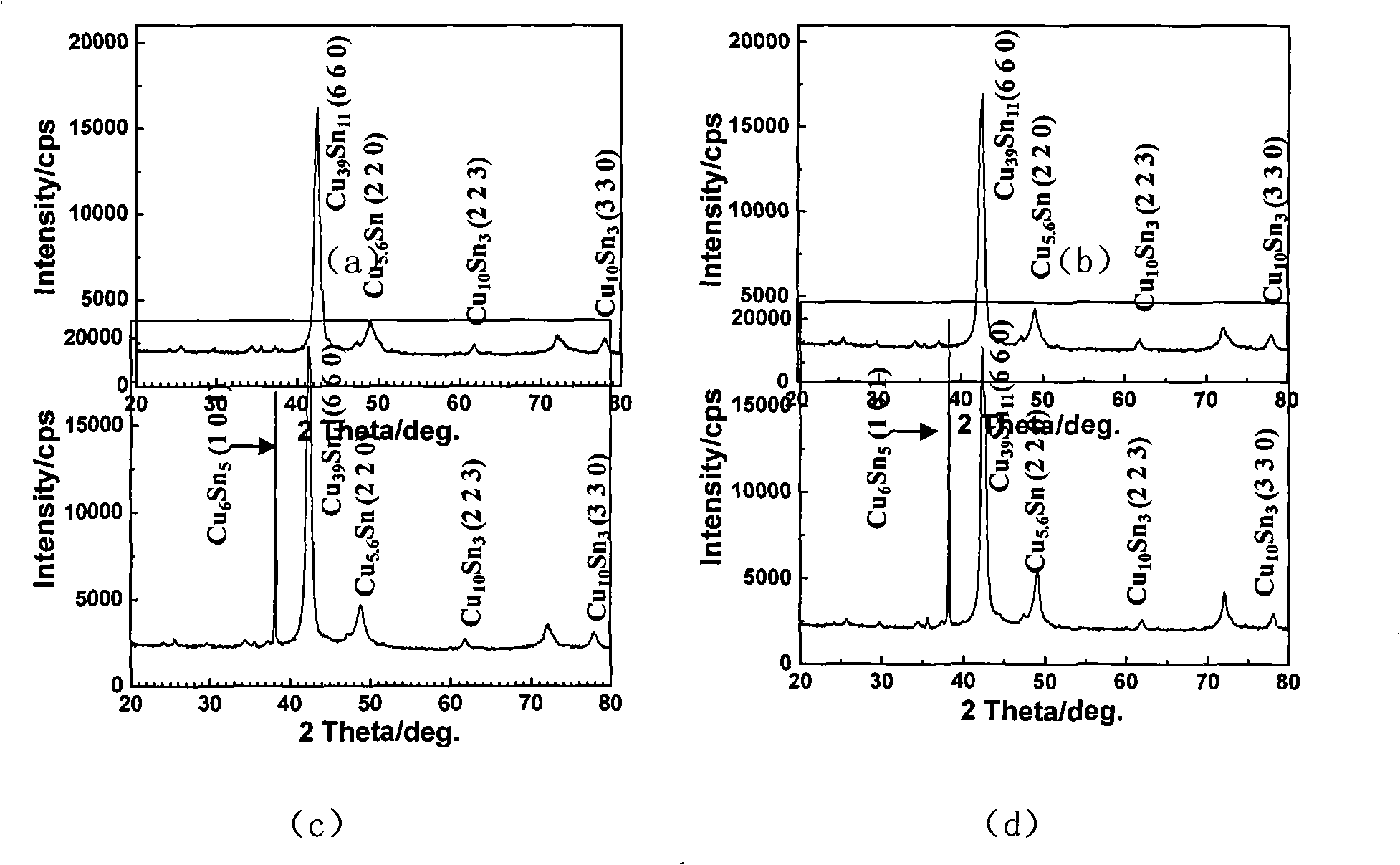

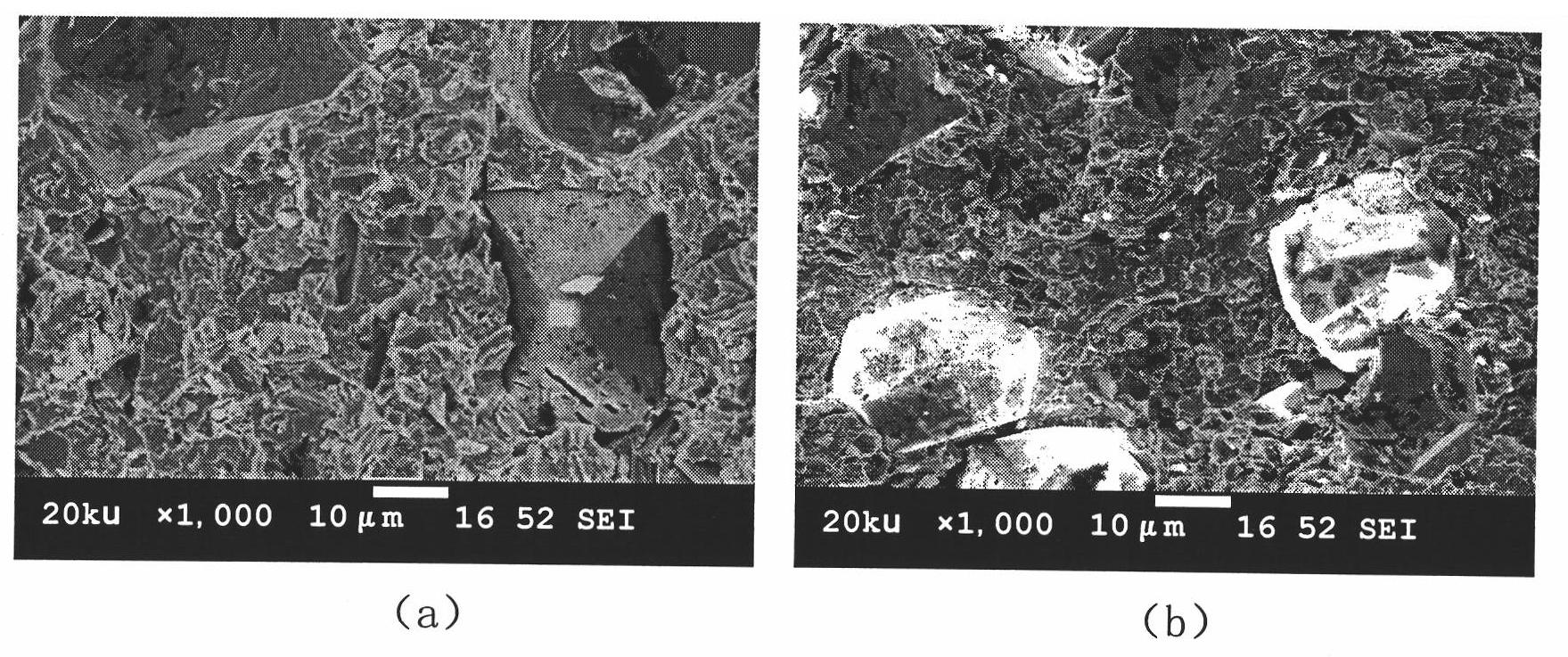

[0069] (1) Raw materials: prepare the metal-based carcass according to the following parts by weight ratio, that is, 35 parts by weight of Cu, 5 parts by weight of Sn, and 35 parts by weight of CuSn 20 , 5 parts by weight Co, 5 parts by weight Ni, 5 parts by weight Al 2 o 3 , 10 parts by weight of SiC, and 1 part by weight of graphite. First, wet mix and stir each component material in a vortex mixer for 4-6 hours, then add the sieved and descaled diamond particles, and stir for about 1 hour to obtain a uniform mixture, or the mixture can be passed through the granulation process A granular bonded body with an outline of less than 1mm is made. The diamond particle size is 40μm and the concentration is 70%;

[0070] (2) Cold press preforming: the mixture or granulated material is supplemented with an appropriate amount of forming agent or lubricant, and is evenly distributed in the steel mold space. After sealing, put it on the lower platen of the press, and slowly lift it t...

Embodiment 2

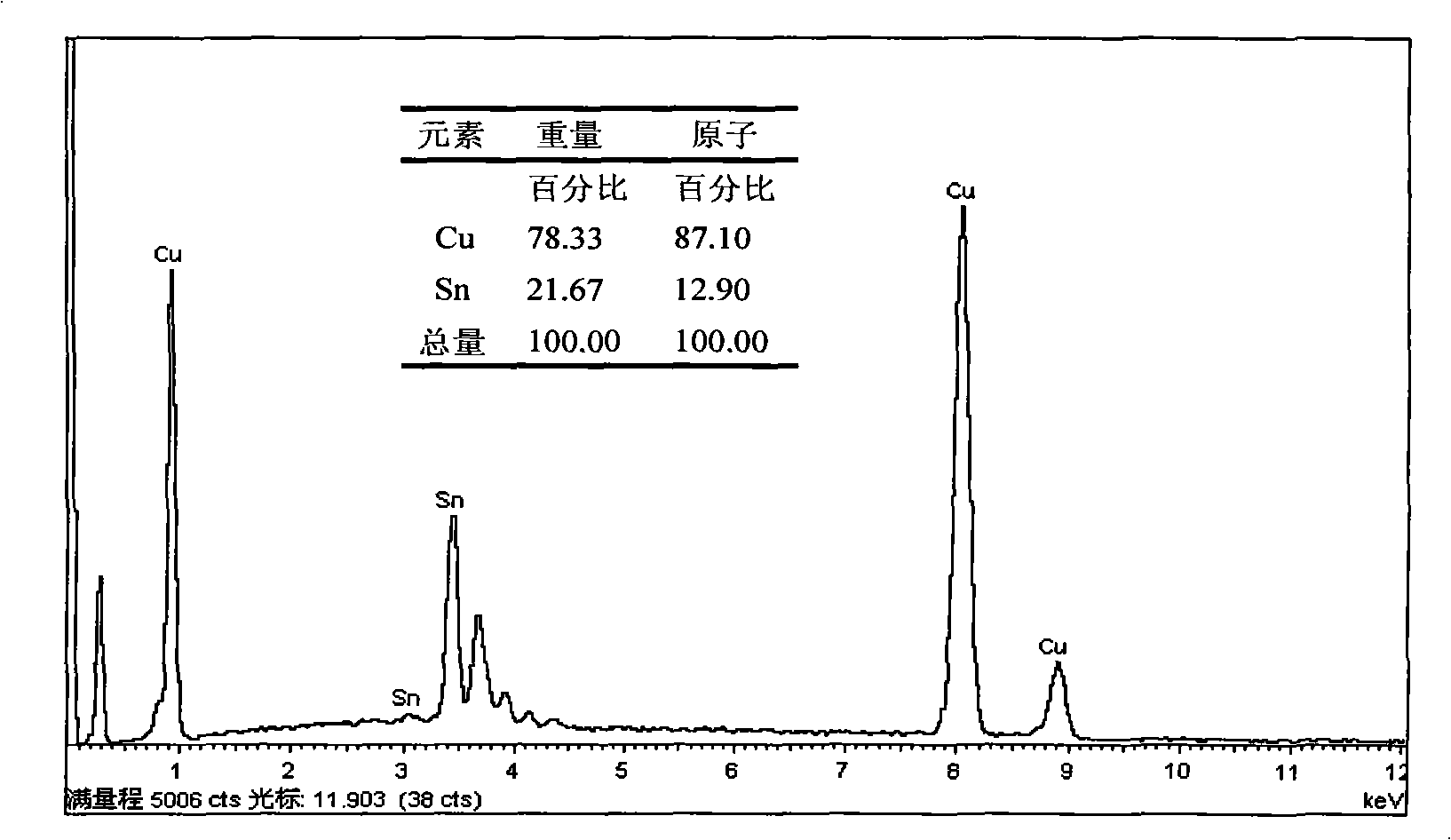

[0077] (1) Material preparation: according to 78 parts by weight of Cu, 22 parts by weight of Sn, plus 1 part by weight of Al 2 o 3 , 1 weight part of SiC, 1 weight part of graphite to prepare metal carcass raw materials. First, mix the above raw materials in a vortex mixer for 4-6 hours, then add the sieved and descaled diamond particles, stir for about 1 hour to obtain a uniform mixture, and then pass the granulation process to make the mixture with a shape less than 1mm of granular adhesives. The diamond particle size is 50μm and the concentration is 55%;

[0078] (2) Cold press preforming: the mixture or granulated material is supplemented with an appropriate amount of forming agent or lubricant and evenly distributed in the steel mold space. After sealing, put it on the lower platen of the press, and slowly lift it to contact with the upper platen. and apply pressure

[0079] 3.92×10 3 -5.88×10 3 MPa and hold the pressure in a timely manner to obtain a formed compac...

Embodiment 3

[0087] (1) material preparation: according to 50 parts by weight of CuSn 20 , 38 parts by weight of Cu, and 12 parts by weight of Sn to prepare a metal-based carcass. Stir the above raw materials in a vortex mixer for 4-6 hours, then add the sieved and descaled diamond particles, stir for about 1 hour to obtain a uniform mixture, and then pass the mixture through the granulation process to make a shape less than 1mm granular adhesive. The diamond particle size is 55μm and the concentration is 55%;

[0088] (2) Cold press preforming: the mixture or granulated material is supplemented with an appropriate amount of forming agent or lubricant, and is evenly distributed in the steel mold. After sealing the cover, put it on the lower platen of the press, and slowly lift it to contact with the upper platen. Apply pressure 3.92×10 3 -5.88×10 3 MPa and hold the pressure at the right time to obtain the formed green compact. After inspecting the defects of delamination, cracks, edge ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com