Method for employing anaerobic-aerobic combined biological filter to process domestic sewage

An anaerobic biological filter and domestic sewage technology, which is applied in the field of domestic sewage treatment, can solve the problems of difficulty in reaching, poor effluent quality, and poor P and N removal effect, and achieves easy cleaning, improved effluent quality, and good efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

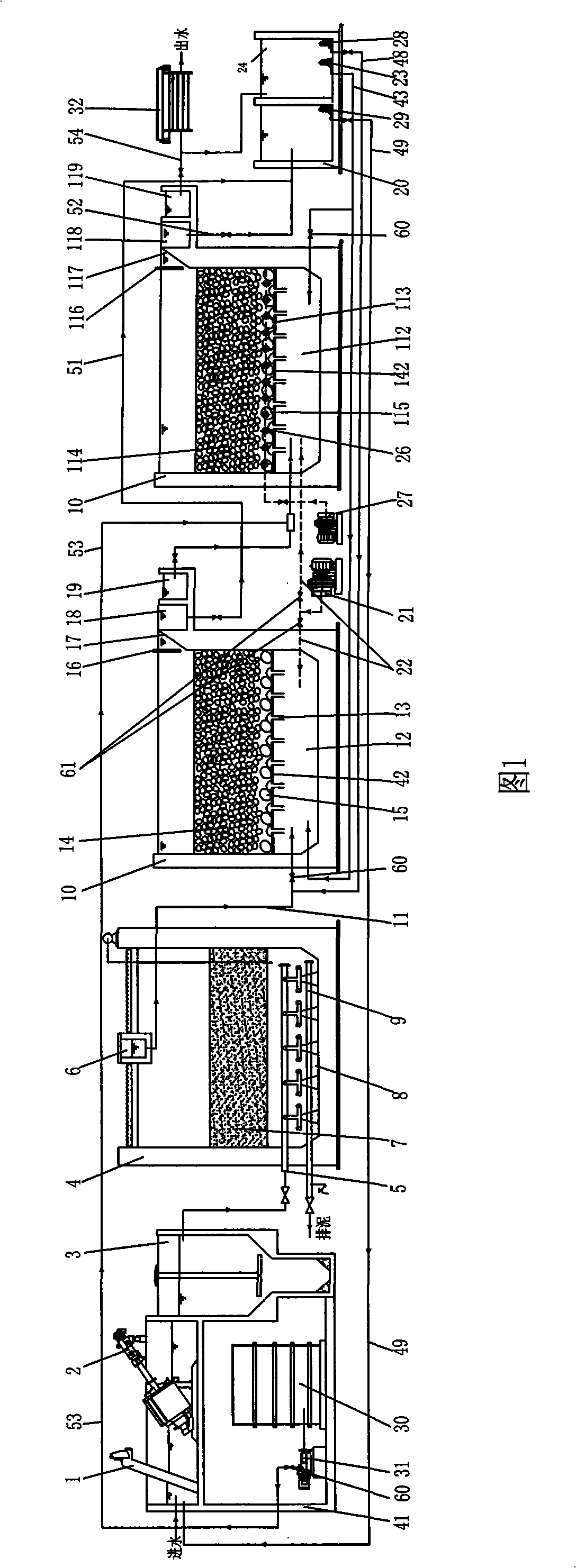

[0015] Specific embodiment one: the method for treating domestic sewage using anaerobic-aerobic combined biofilter described in this embodiment is realized according to the following steps:

[0016] Step 1. The sewage to be treated enters the pretreatment system. The sewage to be treated enters the swirl grit chamber 3 on the pretreatment system after the large debris is intercepted by the grille in the pretreatment system. The hydraulic power of the swirl grit chamber 3 The surface load is controlled at 130~140m 3 / m 2 h and keep the hydraulic retention time at 40-50s;

[0017] Step 2. The sewage treated in step 1 flows into it from the lower part of the Efficient biological-floc filtering and precipitation device in the way of water distribution upward, and forms a layer of suspension in the biological-floc filtering sedimentation tank. Sludge layer 7 (suspended sludge layer 7 can be formed by adjusting the rising flow rate of influent), and the suspended solids and 80% (b...

specific Embodiment approach 2

[0021] Specific embodiment two: the method for processing domestic sewage described in this embodiment also includes step six: filter tank backwashing step: after stopping water inflow, at first use backwash fan 21, backwash trachea 22 to BIOFOR anaerobic biological filter Carry out gas backwashing with BIOFOR biological aerated filter; then open backwash water pump 23 and corresponding valve, utilize the clear water flowing out from the upper part of BIOFOR biological aerated filter to BIOFOR anaerobic biological filter and BIOFOR biological aerated filter Carry out air-water backwashing; After air-water backwashing, first only close backwash fan 21, do not close backwash water pump 23, carry out water backwashing (rinsing); Above-mentioned backwash waste water is collected and returned to the pretreatment system At the water inlet. Air backwashing mainly serves the purpose of loosening the filter material. Air-water backwashing is the main step of the backwashing procedure. ...

specific Embodiment approach 3

[0022] Specific implementation method three: In this embodiment, when backwashing the BIOFOR anaerobic biological filter and the BIOFOR aerated biological filter, the control water backwashing intensity is 20m 3 / (m 2h), gas backwash intensity 50m 3 / (m 2 h); the ratio of air backwash time: air-water backwash time: water backwash time is 1:5:2. Both BIOFOR anaerobic biological filter and BIOFOR aerated biological filter adopt three steps of air backwash, air-water backwash and water backwash for backwashing. The backwash time of BIOFOR anaerobic biological filter is 40min, and the backwash cycle is 24h. The backwash time of BIOFOR biological aerated filter is 40min, and the backwash cycle is 60h. Other steps are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com