Adhesive sheet for marking

An adhesive sheet and marking technology, applied in the direction of adhesive types, polyurea/polyurethane adhesives, film/flake adhesives, etc. Sexual problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

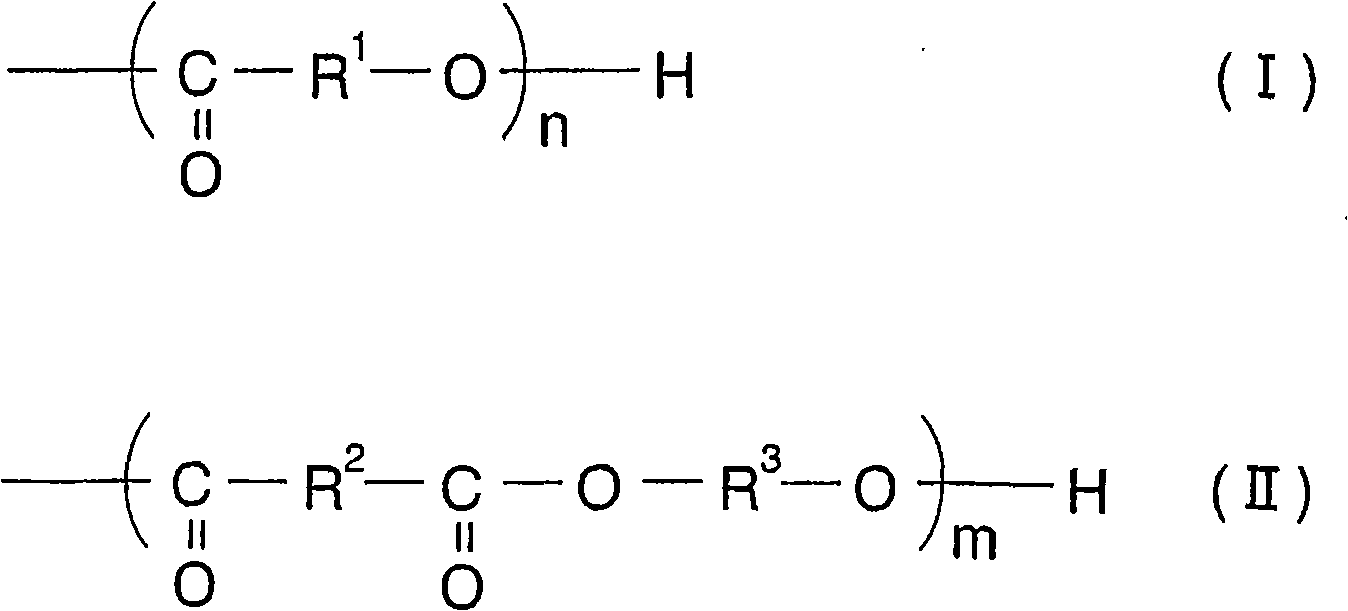

Method used

Image

Examples

Embodiment 1

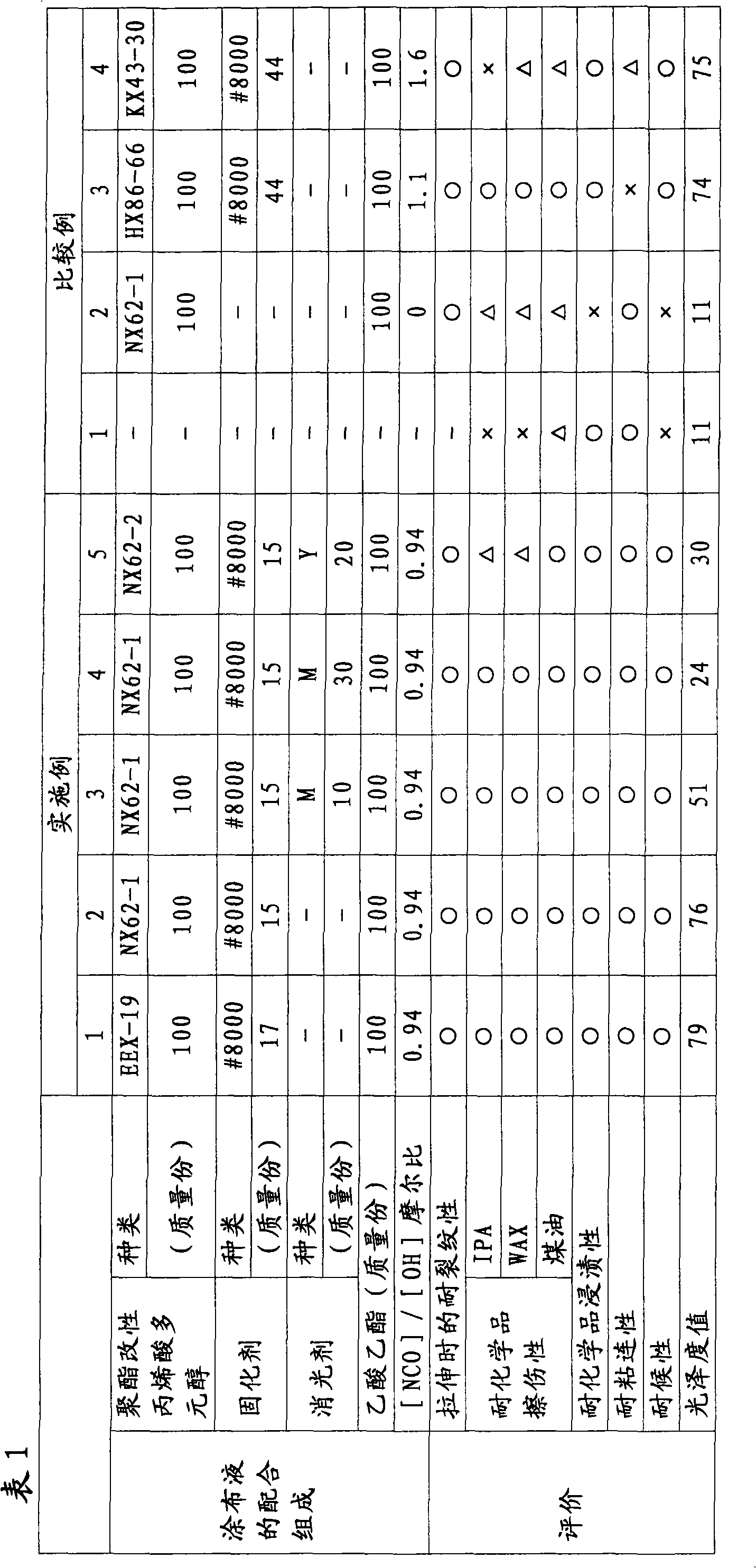

[0127] As the non-vinyl chloride resin base material, a polyester thermoplastic elastomer film [manufactured by Kurabo Industries, Ltd., trade name "ES-9470BK"] with a thickness of 100 μm was used. On the release-treated surface of a release sheet [manufactured by Oji Paper Co., trade name "SP-12HL Kai"] with a thickness of 170 μm that has been subjected to release treatment on polyethylene-laminated paper with a silicone-based release agent, apply An acrylic adhesive [manufactured by Lintec, trade name "SK", containing an epoxy compound crosslinking agent] was dried to form an adhesive layer with a thickness of 30 μm.

[0128] On one side surface of the above-mentioned polyester thermoplastic elastomer film, a release sheet with the above-mentioned adhesive layer is pasted. The mixture layer is transferred to the surface.

[0129] In addition, polyester-modified acrylic polyol resin [manufactured by Asia Industry Co., Ltd., trade name "EEX-19", resin Tg = 47°C, Mw = 68,000, ...

Embodiment 2

[0133] In Example 1, as the polyester-modified acrylic polyol resin, [manufactured by Asia Industry Co., Ltd., trade name "NX62-1", resin Tg = 47°C, Mw = 38,000, solvent toluene, at 25°C The viscosity is 3000mPa·s, the solid content concentration is 54.9% by mass] 100 parts by mass, and the amount of the curing agent "#8000" (same as above) is changed to 15 parts by mass, and the same as in Example 1 According to the operation, a coating solution having a solid content concentration of 29% by mass was prepared, and an adhesive sheet for marking was produced.

[0134] Table 1 shows the performance evaluation results of the pressure-sensitive adhesive sheet for marking.

Embodiment 3

[0136] In Example 2, a matting agent [manufactured by Asia Industry Co., Ltd., trade name "Matting Agent M", a polycarbonate resin with an average particle diameter of 3.5 μm, a dispersion medium of xylene / cyclohexanone, and a solid content of Concentration: 7% by mass] 10 parts by mass, and the same operation as in Example 2 was carried out to prepare a coating liquid having a solid content concentration of 28% by mass, and further produce an adhesive sheet for marking.

[0137] Table 1 shows the performance evaluation results of the pressure-sensitive adhesive sheet for marking.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com