Method for preparing transparent super-hydrophobic automatic cleaning coating

A self-cleaning coating and super-hydrophobic technology, applied in antifouling/underwater coatings, biocide-containing paints, etc., can solve the problems of expensive equipment and difficult preparation, and achieve low cost, simple process, and easy-to-obtain raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Treatment of the substrate:

[0032] Surface-level glass slides were ultrasonically treated with toluene, acetone, chloroform, ethanol, and distilled water for 10 min, respectively, to remove various impurities attached to the substrate surface. 2 SO 4 and H at a mass concentration of 30% 2 o 2 (v:v=7:3) in the mixed solution, heated and boiled for 20 minutes until no bubbles overflowed, rinsed with a large amount of distilled water after cooling, and then dried with nitrogen, and set aside.

[0033] (2) Preparation of solution:

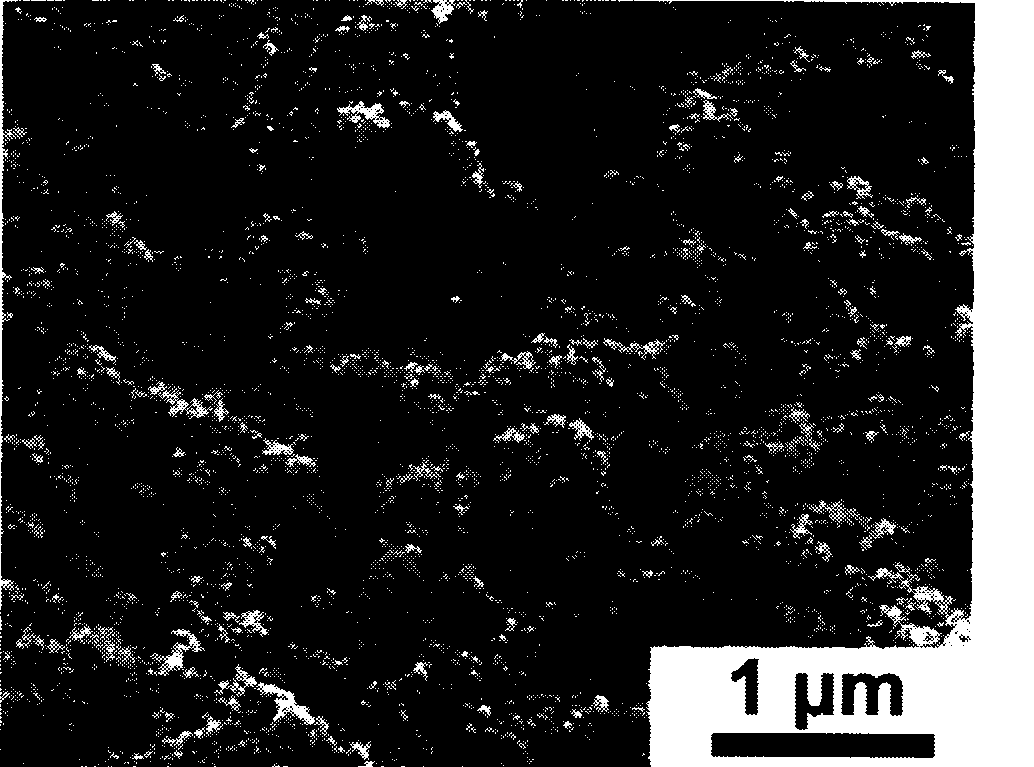

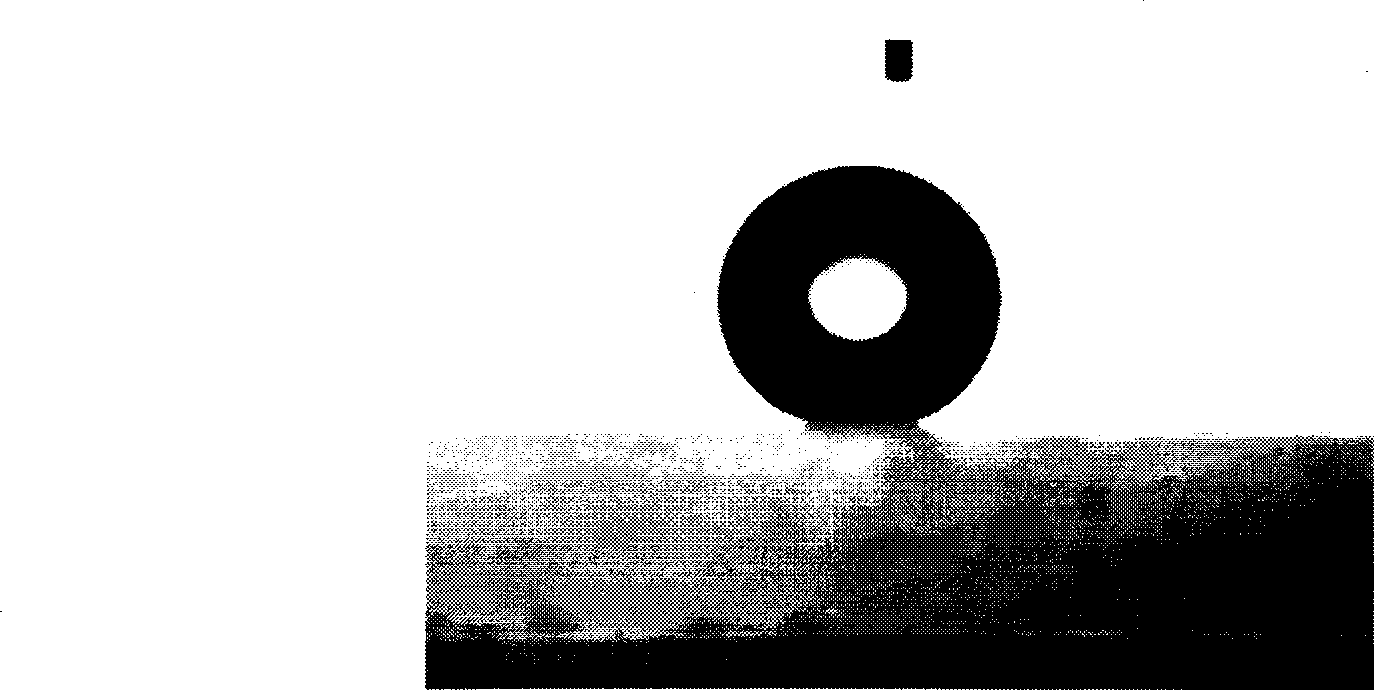

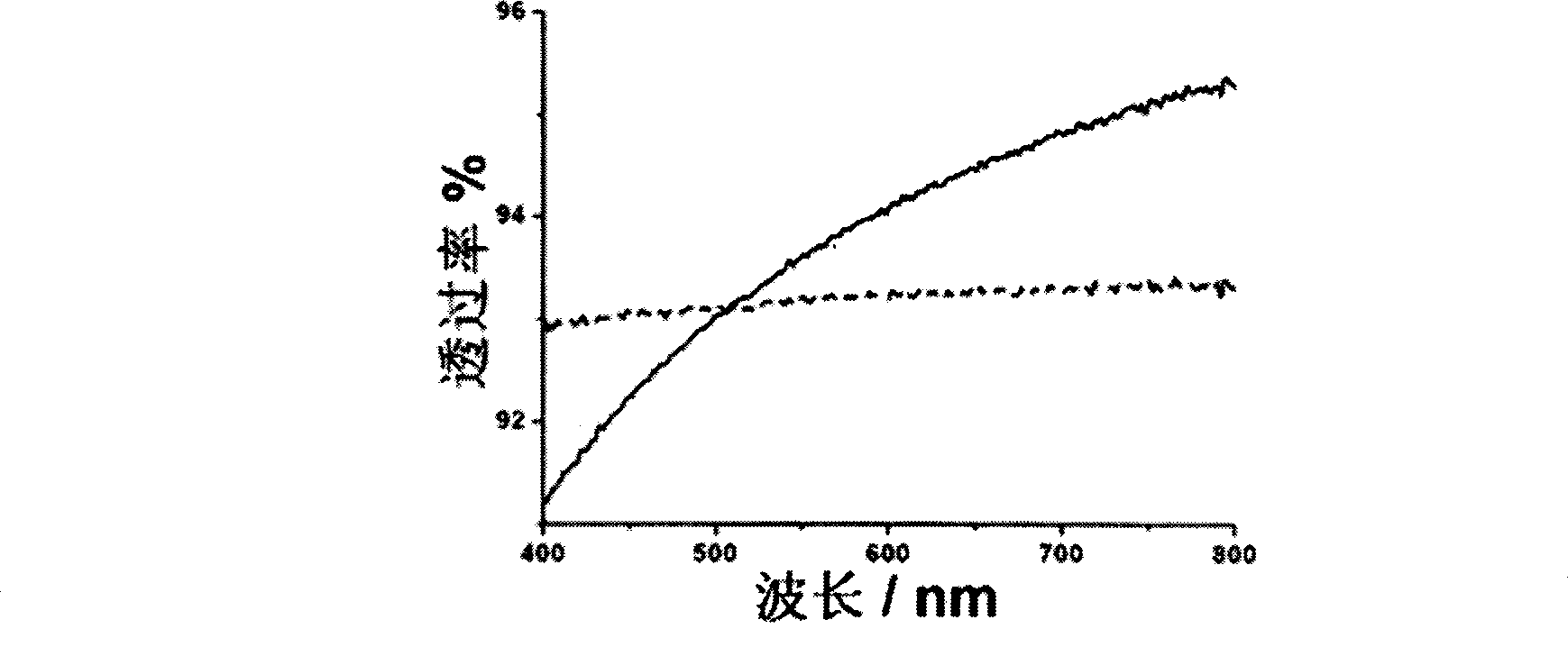

[0034] 0.3g of SiO produced by Sigma-Aldrich with a particle size of 10nm 2 Inorganic nanoparticles were dissolved in a mixed solution of 100mL isopropanol and deionized water, the volume ratio of isopropanol to deionized water was 1:4, and the SiO 2 The nanoparticles are uniformly dispersed and ready for use; then 0.2 g of polydimethyldipropylenelamine hydrochloride is dissolved in 100 mL of deionized water, and the solution is unifo...

Embodiment 2

[0043] (1) Treatment of the substrate:

[0044] Surface-level glass slides were ultrasonically treated with toluene, acetone, chloroform, ethanol, and distilled water for 10 min to remove various impurities attached to the surface of the substrate. 2 SO 4 and 30% mass concentration of H 2 o 2 (v:v=7:3) in the mixed solution and boiled (~20min) until no bubbles overflow. After cooling, rinse with a large amount of distilled water, then blow dry with nitrogen, and set aside.

[0045] (2) Solution preparation:

[0046] 0.4g of TiO produced by Sigma-Aldrich with a particle size of 20nm 2 Nanoparticles were dissolved in a mixture of 100mL acetone and deionized water, the volume ratio of acetone and deionized water was 1:2, and the TiO 2The nanoparticles are uniformly dispersed and ready for use; dissolve 0.3g of polyacrylamine in 100mL of water, and dissolve evenly before use.

[0047] (3) Micro-nano composite surface preparation:

[0048] Soak the glass substrate processed...

Embodiment 3

[0054] (1) Treatment of the substrate:

[0055] Surface-level quartz slices were ultrasonically treated with toluene, acetone, chloroform, ethanol, and distilled water for 10 min to remove various impurities attached to the surface of the substrate, and then heated in 98% H 2 SO 4 and 30% mass concentration of H 2 o 2 (v:v=7:3) in the mixed solution and boiled (~20min) until no bubbles overflow. After cooling, rinse with a large amount of distilled water, then blow dry with nitrogen, and set aside.

[0056] (2) Solution preparation:

[0057] 0.4g of SiO produced by Sigma-Aldrich with a particle size of 14nm 2 Nanoparticles were dissolved in a mixture of 100 mL ethanol and deionized water, the volume ratio of ethanol to deionized water was 1; 2, and the SiO 2 The nanoparticles are uniformly dispersed and ready for use; dissolve 0.5g of polyacrylamine in 100mL of water and dissolve evenly before use.

[0058] (3) Micro-nano composite surface preparation:

[0059] Soak th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com