Loaded type catalyst for preparing elemental phosphorus and preparation method thereof

A supported catalyst, elemental phosphorus technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of easy crystallization catalytic activity, low conversion rate, complex process, etc. Effects of activity and selectivity, large aspect ratio, and low thermal decomposition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

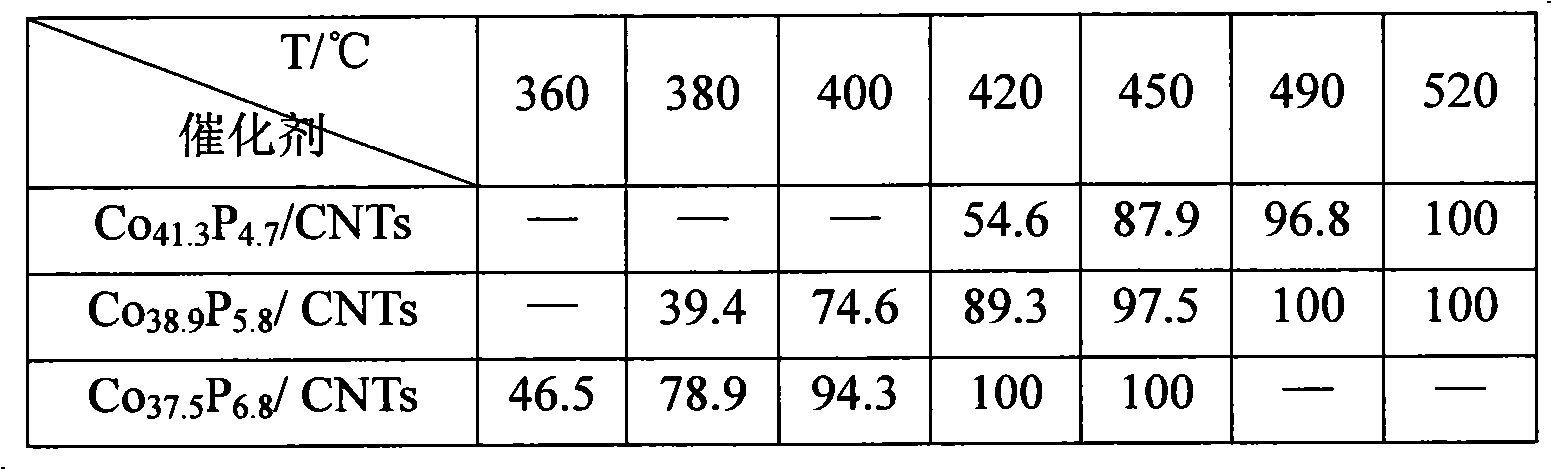

Embodiment 1

[0022] Dissolve 0.048mol of cobalt sulfate and 0.070mol of sodium citrate in deionized water, then add 0.384mol of sodium hypophosphite, 0.136mol of ammonium sulfate and 1.0g of treated CNTS, and then dilute the reaction solution with deionized water to 200mL, in the reaction solution, Co 2+ The concentrations of ions, sodium citrate, sodium hypophosphite and ammonium sulfate are 0.24mol / L, 0.35mol / L, 1.92mol / L and 0.68mol / L respectively; the pH of the reaction solution is adjusted to 9.0 with concentration of 25% ammonia water Around, at a temperature of 90°C, fully stir to form a black powder precipitate; separate the precipitate and wash it with deionized water until the supernatant reaches neutrality, and finally wash twice with absolute ethanol and place the precipitate in Preserved in absolute ethanol, the precipitate is fresh Co-P / CNTS amorphous alloy. It has been detected that the mass percent of Co and P in the product is Co 38.9 P 5.8 / CNTS, the specific surface a...

Embodiment 2

[0024] Change the sodium hypophosphite addition in Example 1 to 0.240mol, and the concentration in the reaction solution is 1.20mol / L, and all the other steps and conditions are the same as in Example 1. The resulting product has been tested and shown that the mass percentages of Co and P are: Co 41.3 P 4.7 / CNTS, the specific surface area is 72.32m 2 / g.

Embodiment 3

[0026] Change the sodium hypophosphite addition in Example 1 to 0.624mol, and the concentration in the reaction solution is 3.12mol / L, and all the other steps and conditions are the same as in Example 1. The resulting product has been tested and shown that its Co, P mass percent composition is: Co 37.5 P 6.8 / CNTS, the specific surface area is 79.52m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com