Method for utilizing refinery tail gas and coke oven gas efficiently and rationally

A technology for coke oven gas and refinery, which is applied in the field of industrial exhaust gas utilization, can solve the problems of difficult production mode, high recovery cost, inhibition of enthusiasm for recovery and utilization of refinery exhaust gas, etc., so as to eliminate energy waste, solve the problem of exit, and realize utilization value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

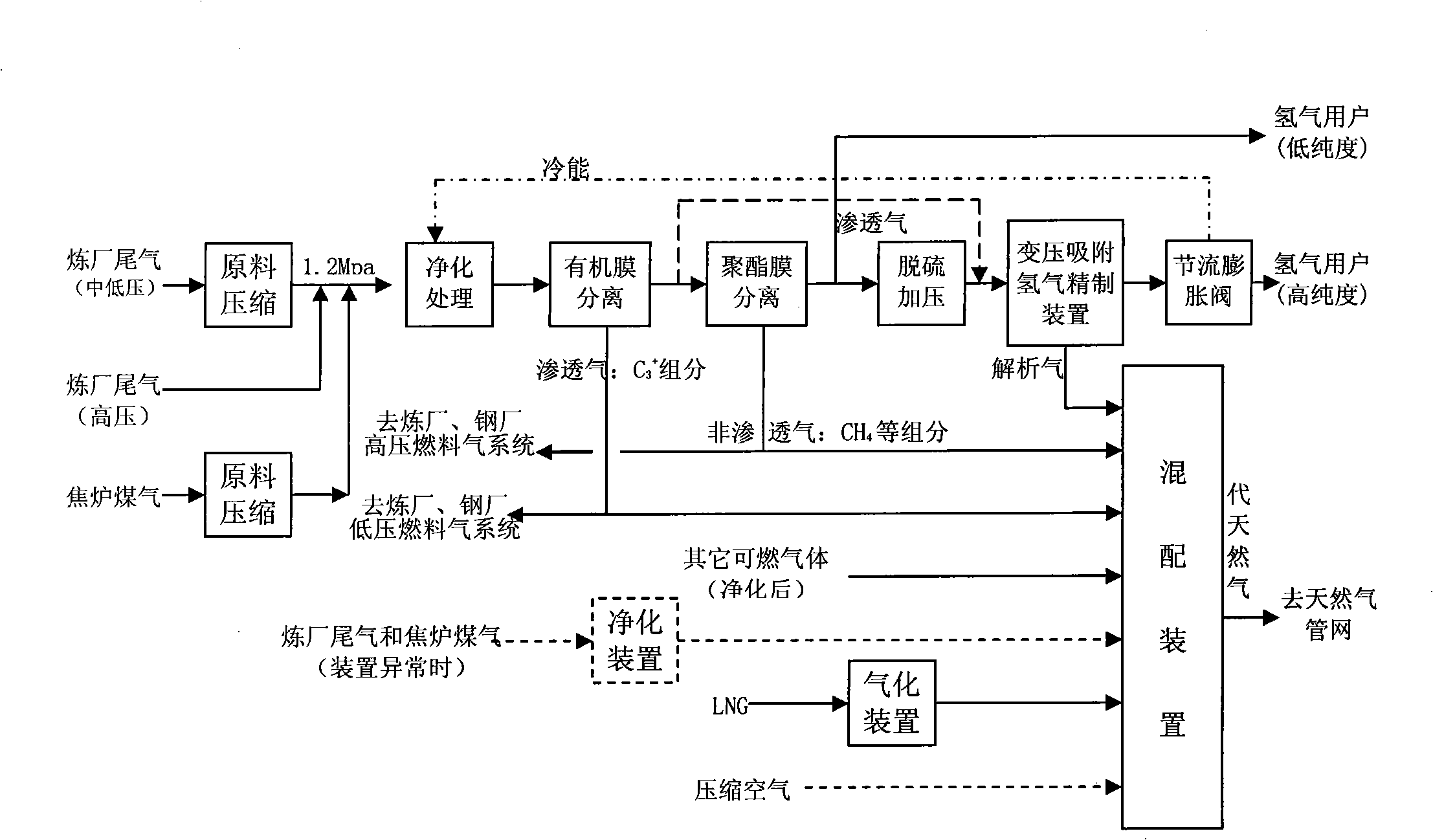

[0073] There is a backup gas source plant for natural gas accidents in a certain city, surrounded by an oil refinery and coking plant. In order to make full use of refinery tail gas and coke oven gas, after negotiations, the three companies reached a consensus and jointly designed a set of integrated process for comprehensive utilization of refinery tail gas and coke oven gas, such as figure 1 As shown, the device is built in the gas source plant and communicated with the refinery and coking plant through pipelines.

[0074] (1) The normal operation of the hydrogen purification unit

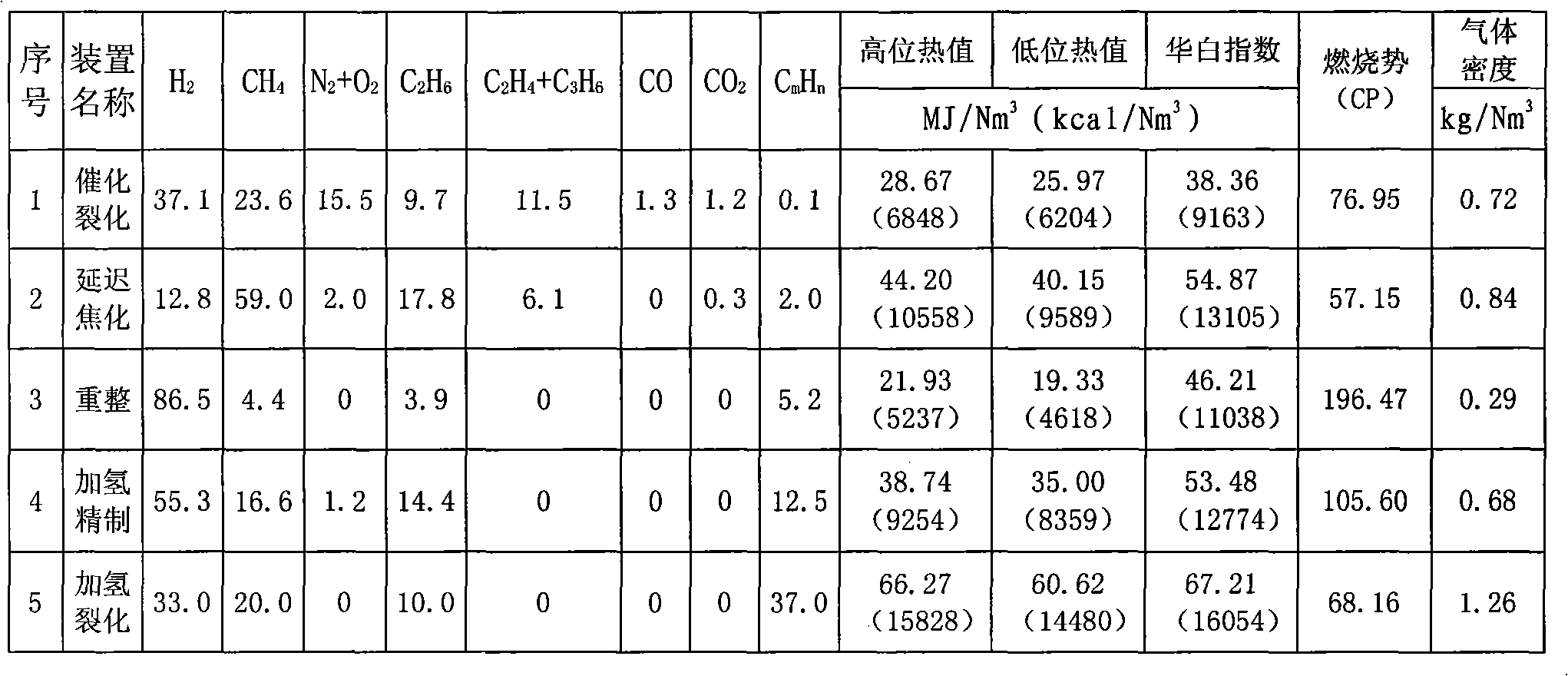

[0075] The refinery tail gas of all production units of the refinery is sent into the process of the present invention in 2 ways according to different pressures, and the flow rate and pressure are respectively 12000Nm 3 / h, 5800Nm 3 / h; 1.5Mpa, 0.6Mpa; there is a coke oven gas feed into the device in the coking plant, and the flow rate and pressure are 8500Nm 3 / h; 0.55Mpa, enter each gas sou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com