Integrated pre-denitrification and denitrogenation biological filter sewerage treatment process

A pre-denitrification and biofilter technology, applied in the direction of biological water/sewage treatment, sustainable biological treatment, multi-stage water/sewage treatment, etc., can solve the problems of non-removal and water pollution, and achieve high treatment load, Short hydraulic retention time and good removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

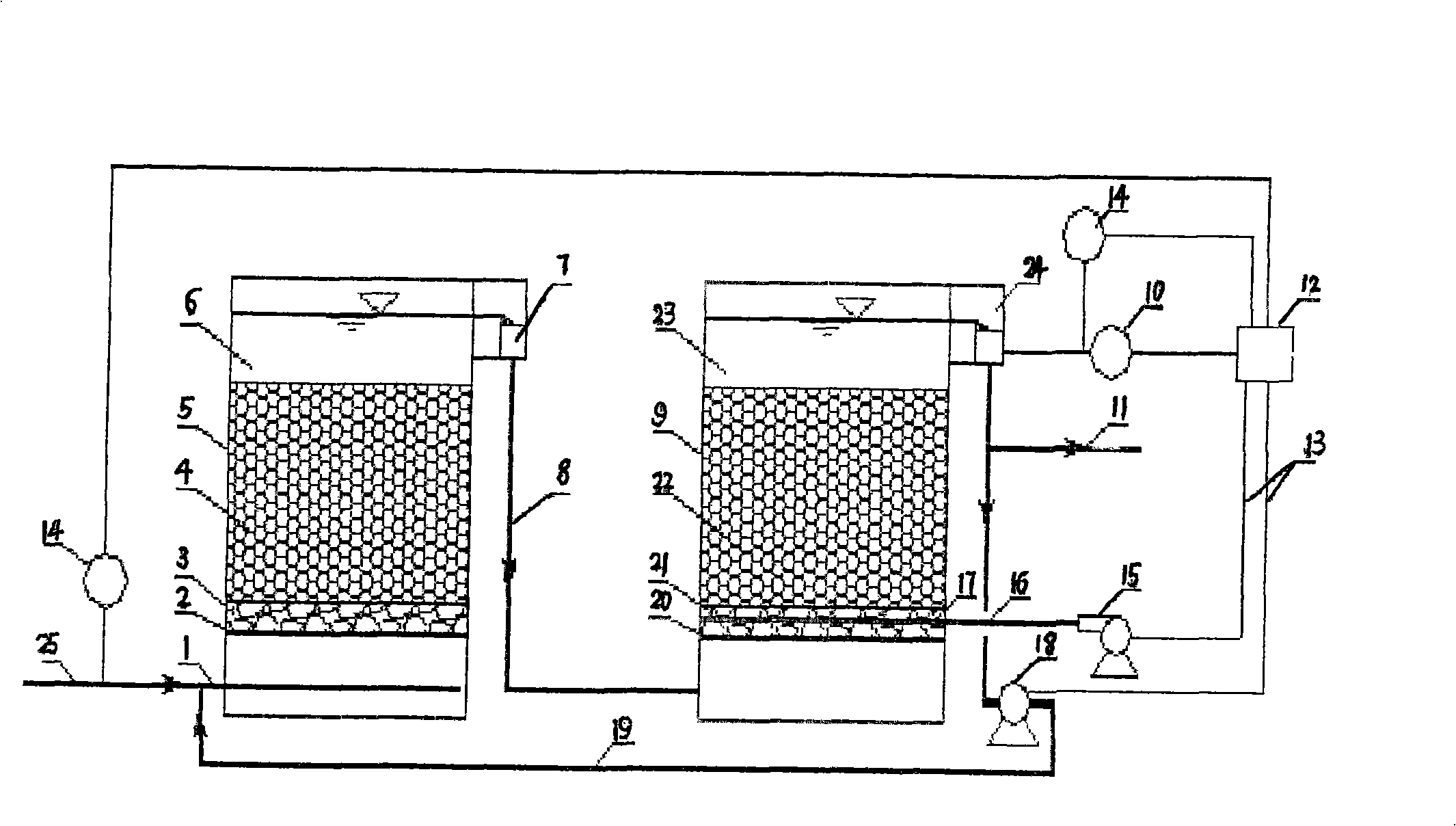

[0011] Such as figure 1 As shown, the sewage to be treated from the sewage inlet pipe 25 is first mixed with the effluent from the part of the aerobic nitrification biological filter 9 that flows back from the backflow pump 18 through the backflow pipe 19 to the water inlet, and then jointly from the anoxic denitrification biological The water inlet pipe 1 of the filter tank 5 enters the anoxic denitrification biological filter tank 5, which is always in an anoxic state during operation and keeps the dissolved oxygen solubility in the tank less than 0.5mg / L. The reflux liquid contains a large amount of nitrate nitrogen, and the sewage contains a large amount of organic matter. When the mixed sewage flows through the spherical light porous biological ceramsite layer 4 in the anoxic denitrification biological filter 5, the denitrification layer attached to it will The bacteria use the organic matter in the sewage as a carbon source, and through the physiology and metabolism of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com