Composite light weight gypsum wallboard

一种石膏板、轻量的技术,应用在家用墙、纸/纸板层状产品、陶瓷制品等方向,能够解决粘结层难适用、减少成品墙板芯硬度等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1 Sample gypsum slurry formula

[0037] The gypsum slurry formula is shown in Table 1 below. All values in Table 1 are expressed in weight percent based on the weight of dry stucco. Values in parentheses are dry weight in pounds (lb / MSF).

[0038] Table 1

[0039] Component

Formulation A

Formulation B

[0040] Plaster (lb / MSF)

(732)

(704)

Sodium trimetaphosphate

0.20(1.50)

0.30(2.14)

Dispersant

0.18(1.35)

0.58 1 (4.05)

2.7(20)

6.4(45)

Plate starch

0.41(3.0)

0

Heat-resistant accelerator (HRA)

(15)

(15)

0.27(2.0)

0.28(2.0)

Paper fiber

0

0.99(7.0)

soap bar *

0.03(0.192)

0.03(0.192)

[0041] Total water volume (lb)

805

852

Water / stucco rat...

Embodiment 2

[0044] Example 2 Preparation of wallboard

[0045] Sample gypsum wallboards were prepared according to U.S. Patent Nos. 6,342,284 and 6,632,550 of Yu et al., which are incorporated herein by reference. The method involves separately generating foam and introducing the foam into the slurry of all other ingredients described in Example 5 of these patents.

[0046] The test results of the gypsum wallboard prepared by using the formula A and formula B of Example 1 and the common control board are shown in Table 2 below. In this example and other examples below, the nail pull resistance, core hardness, and flexural strength tests are all performed in accordance with ASTM C-473. In addition, it should be noted that the usual gypsum wallboard is about 1 / 2 Inches thick and weighs about 1600-1800 pounds per 1000 square feet of material, or lb / MSF. ("MSF" is the standard abbreviation for 1000 square feet in this field; it can be used for the area measurement of boxes, corrugated media a...

Embodiment 3

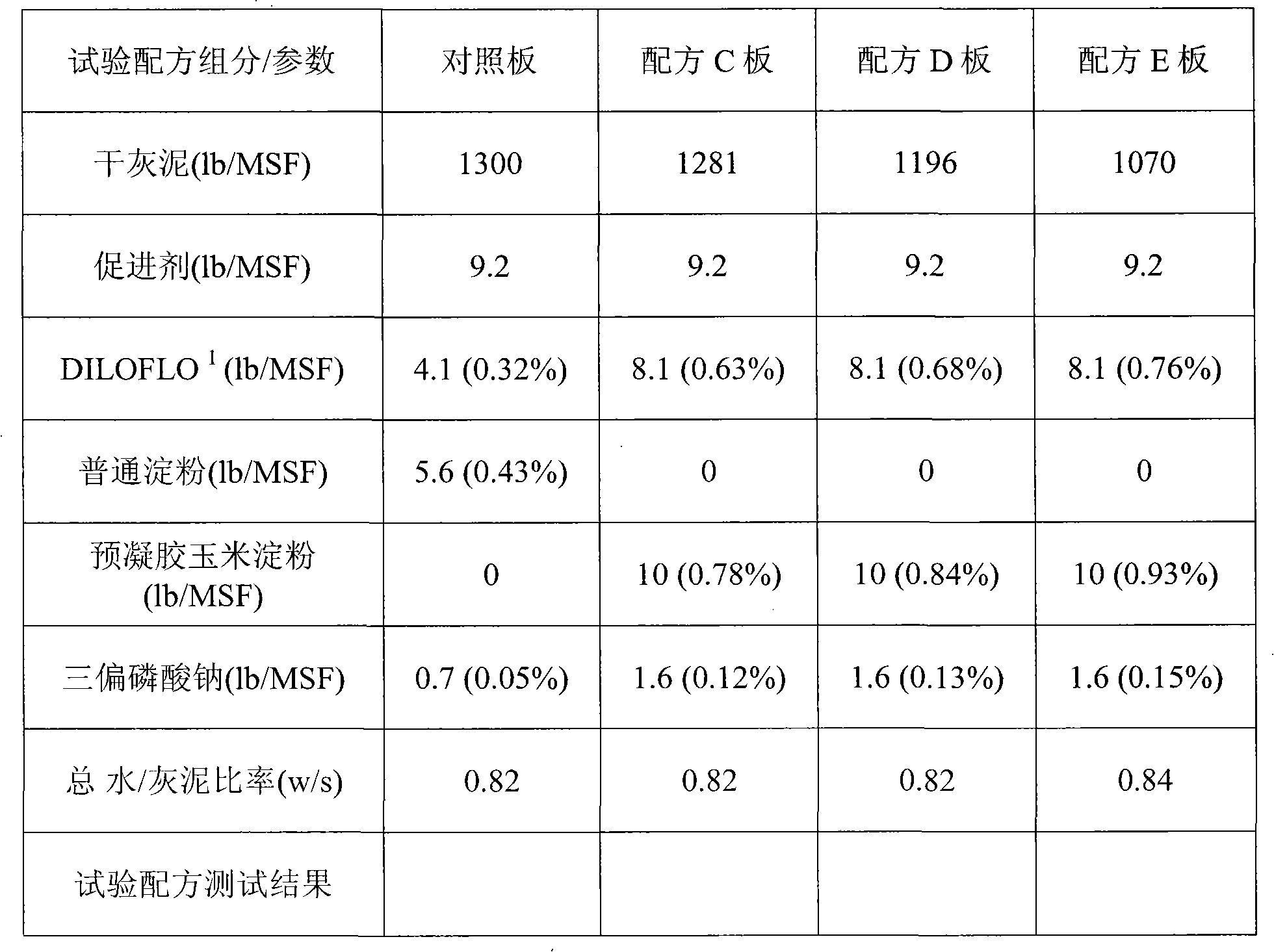

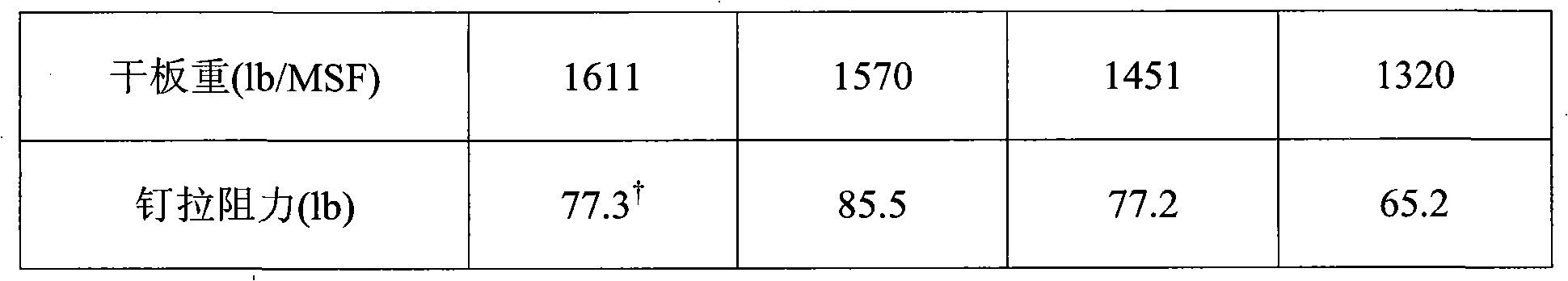

[0053] Example 3 1 / 2 inch gypsum wallboard weight reduction test

[0054] Further examples of gypsum wallboard (boards C, D and E), including slurry formulations and test results, are shown in Table 3 below. The slurry formulation in Table 3 includes the main components of the slurry. The values in parentheses indicate weight percentages based on the weight of dry stucco.

[0055] table 3

[0056]

[0057]

[0058] ASTM standard: 77lb

[0059] 1 DILOFLO is 45% naphthalene sulfonate aqueous solution

[0060] As shown in Table 3, compared with the control plate, plates C, D, and E are made of a large amount of starch, DILOFLO dispersant and sodium trimetaphosphate (the percentage of starch and dispersant is approximately two-fold increase, trimetaphosphate The salt is increased by two to three times) while keeping the w / s ratio constant. However, the weight of the board was significantly reduced, and the strength measured by nail pull resistance was not significantly affecte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| apparent density of powders | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com