Plasticizer for protective films

A technology of protective film and plasticizer, used in instruments, layered products, synthetic resin layered products, etc., can solve the problem of difficult compliance of protective films, and achieve the effect of increasing glass transition temperature and increasing hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

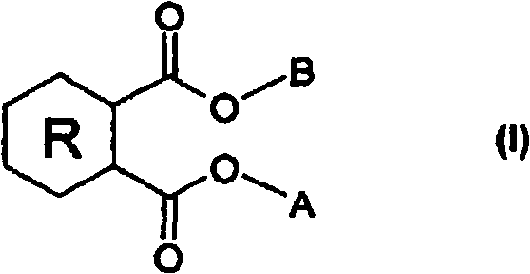

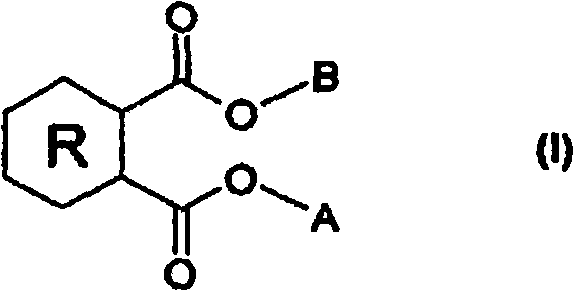

Method used

Image

Examples

Embodiment

[0052] The following examples are used to illustrate the present invention without limiting the scope of the invention:

[0053] In the experiments listed hereinafter, the example number is always given with emphasis in curly brackets {}, {REF} designating a reference example.

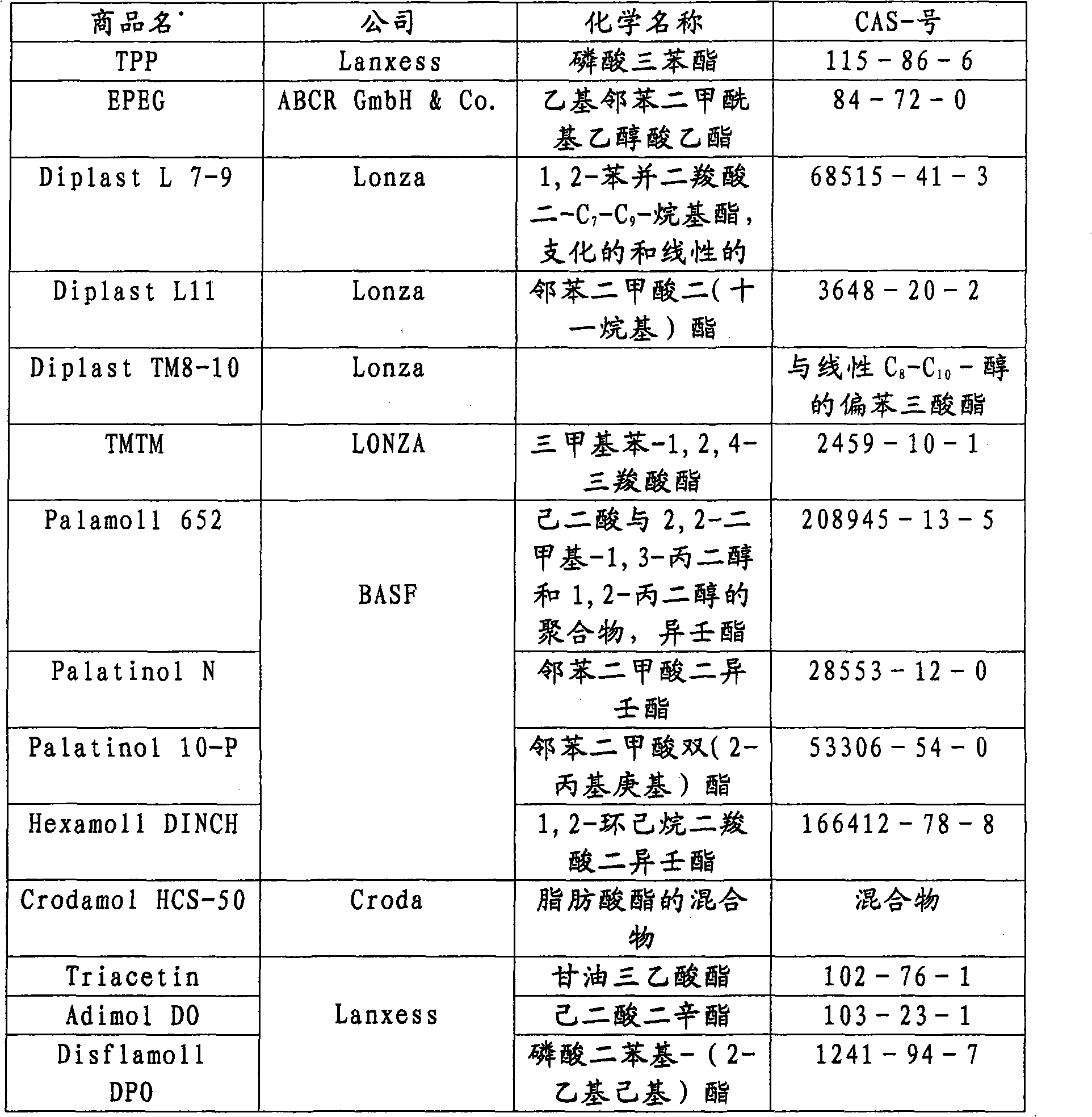

[0054] Experiment 1: TAC-films with different plasticizers

[0055] TAC-films with a thickness of 40 μm were prepared with various plasticizers selected from the following table:

[0056] Table 1: Plasticizers

[0057]

[0058] * ) is also used below as the name

[0059]The preparation was carried out without any increase in temperature using a lacquer vehicle consisting of 16% by weight of cellulose triacetate (60.8% bound acetyl content) in dichloromethane / methanol (90 / 10 v / v). In the case of plasticizers, the paint was filtered through Calmuc (cotton fabric). It is then stored overnight in a rolling cabinet (where dye can be added if necessary). As long as the anti-blocking agent (silica) i...

Embodiment 23

[0103] Example 23: Production of cellulose triacetate with a thickness of 40 μm on an industrial scale cast film

[0104] By 2000kg cellulose triacetate (acetylation degree 2.96), 11330kg methylene chloride: methanol mixture (9: 1v / v), 136kg TPP, 136kg Hexamoll 30 kg of UV-absorber (benzophenone-6), a homogeneous solution is produced under a stirring, cooling and heating cycle and the solution is heated to about 40° C. for degassing. The solution is filtered through a plurality of metal non-woven filters (pore size 5-7 μm) via an intermediate tank at elevated pressure and temperature and then mixed directly (in-line) with the likewise filtered metered-in solution, the resulting The metering solution comprises, in addition to the substances mentioned above, a further dichloromethane:methanol mixture (9:1 v / v) and an antiblocking additive.

[0105] After tempering to 31° C., the solution is cast in the desired thickness (casting gap approx. 235 μm) under a methylene chlori...

Embodiment 24

[0108] Example 24: Glass transition temperature

[0109] Compared with those films using only triphenyl phosphate as plasticizer, in similar example Films prepared under the production conditions of 23 have an increased glass transition temperature:

[0110] Table 8: Glass Transition Temperatures

[0111]

[0112] The water vapor transmission rate of the film is higher than that of other films using TPP alone as a plasticizer. Corresponding films on the other hand have a water vapor transmission rate which is at least 10% lower.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com