Wet method forming micropore filtration separation material and preparation method and application thereof

A technology for microporous filtration and separation of materials, applied in filtration and separation, separation methods, chemical instruments and methods, etc., can solve problems such as easy falling off, achieve good pore uniformity, improve pore uniformity, and improve uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

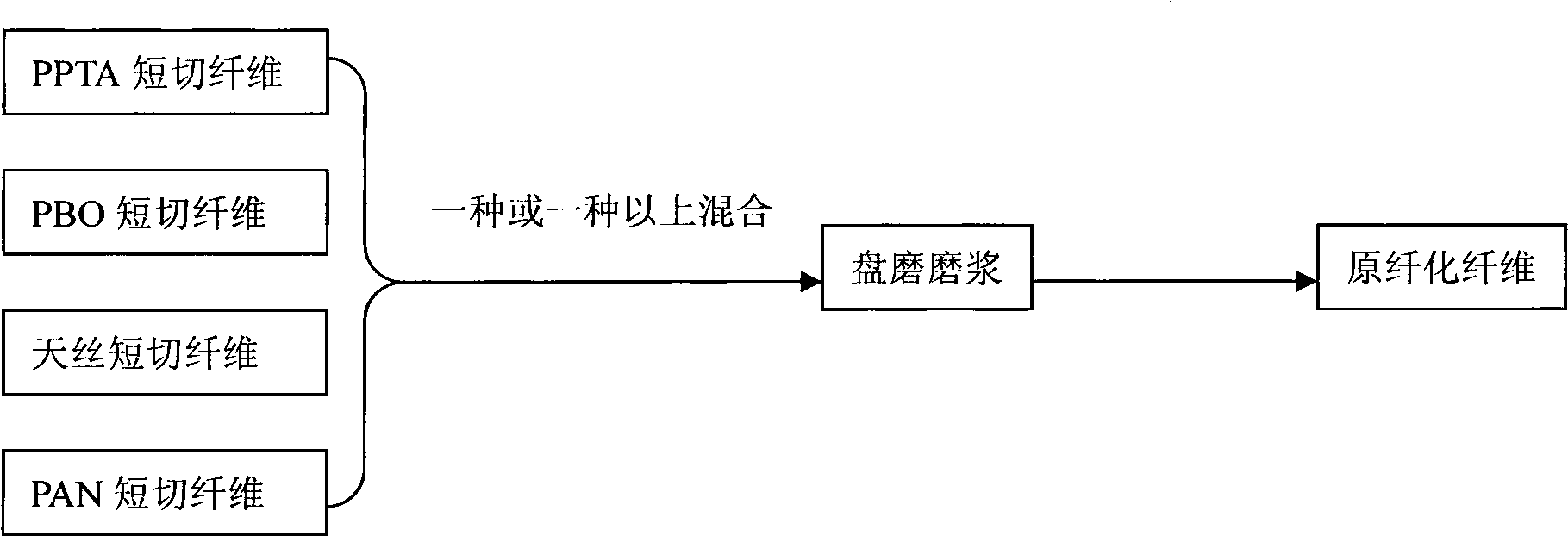

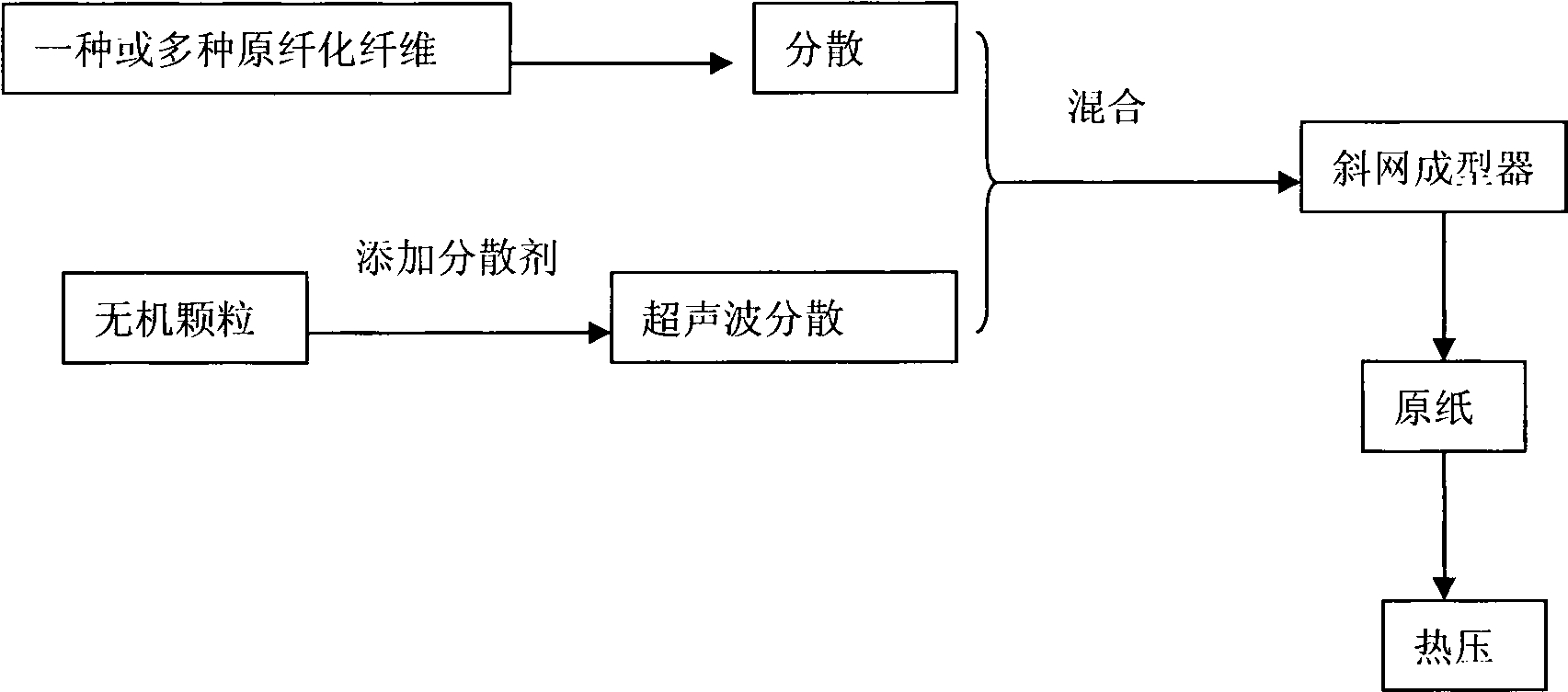

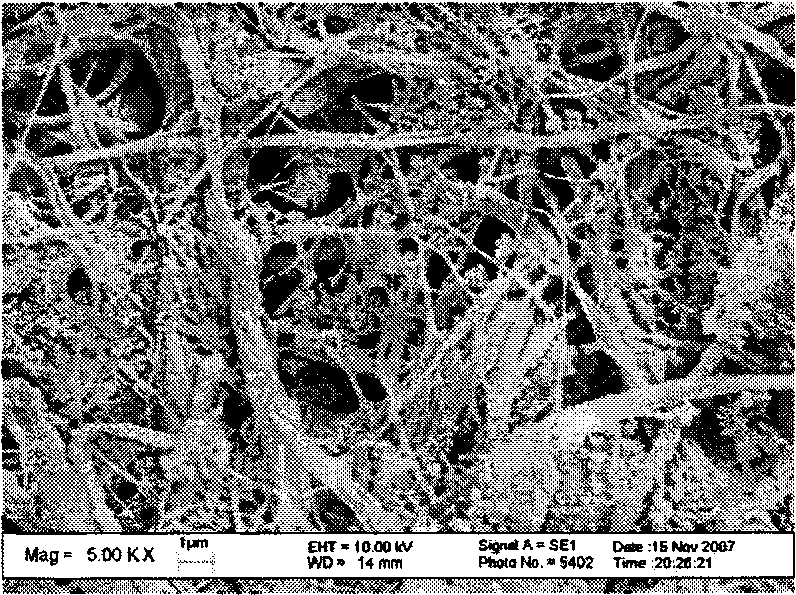

[0033] (1) if figure 1 and figure 2 As shown, get a certain amount of PPTA fiber (trade name: Kevlar, U.S. Dupont company produces, length 5mm, diameter 15 μ m) through refining, the preparation Canada freeness is the PPTA fibrillation fiber of 30ml;

[0034] (2) PPTA fibrillated fibers and PET bonding fibers (manufactured by Kuraray, fiber diameter 3-4μm, fiber length 3mm, cortex melting point 130°C) are uniformly mixed in the aqueous solution at a fiber dry mass ratio of 8:2, Add PAM as a dispersant to obtain a fiber suspension;

[0035] (3) Take 5% SiO of fiber dry weight again 2 Particles (average particle size 300nm) are uniformly dispersed in aqueous solution by adding silane coupling agent;

[0036] (4) Mix the particle suspension in step (3) and the fiber suspension in step (2) evenly to prepare a slurry with a concentration of .

[0037] (5) Make quantitative 30g / m on inclined wire paper machine 2 base paper. The base paper was hot-pressed (line pressure 150Kg...

Embodiment 2

[0039]Adopt the SiO of 0.1% of fiber absolute dry weight in step (3) 2 Particle (average particle diameter is 300nm), all the other steps are with embodiment 1.

Embodiment 3

[0041] In step (3), adopt the SiO of 10% of fiber absolute dry weight 2 Particle (average particle diameter is 300nm), all the other steps are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| free rate | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com