Method for processing composite shot blasting considering both surface peening and polishing

A technology of shot peening and surface strengthening, which is applied in the field of composite shot peening that takes both surface strengthening and polishing into consideration, can solve the problems of increased surface roughness, small decline, and complicated process operations, and achieves high production efficiency and high work efficiency. The effect of mature principle and simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

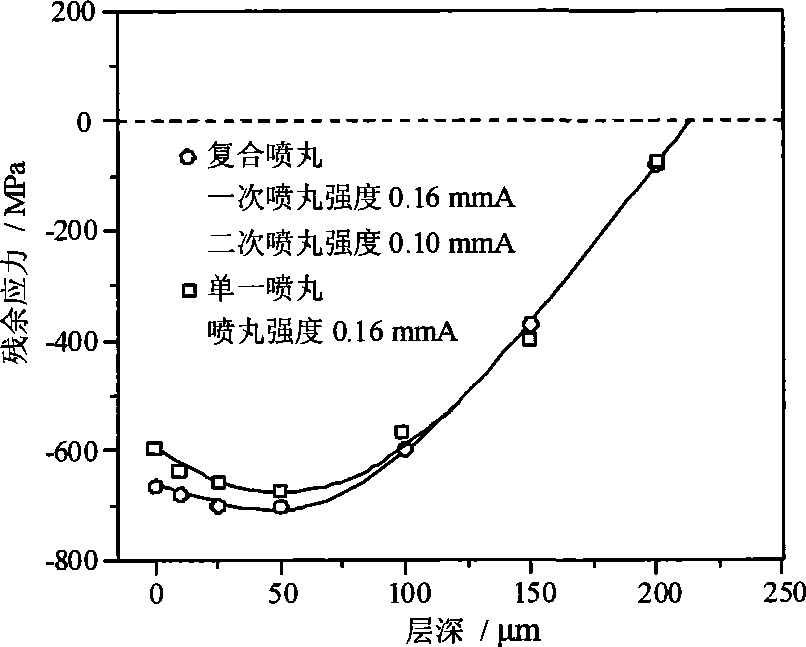

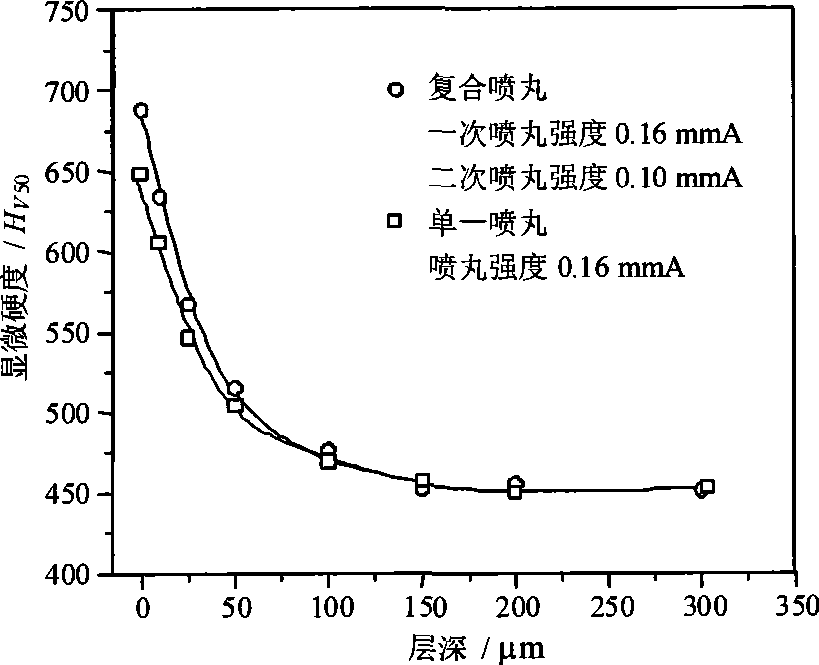

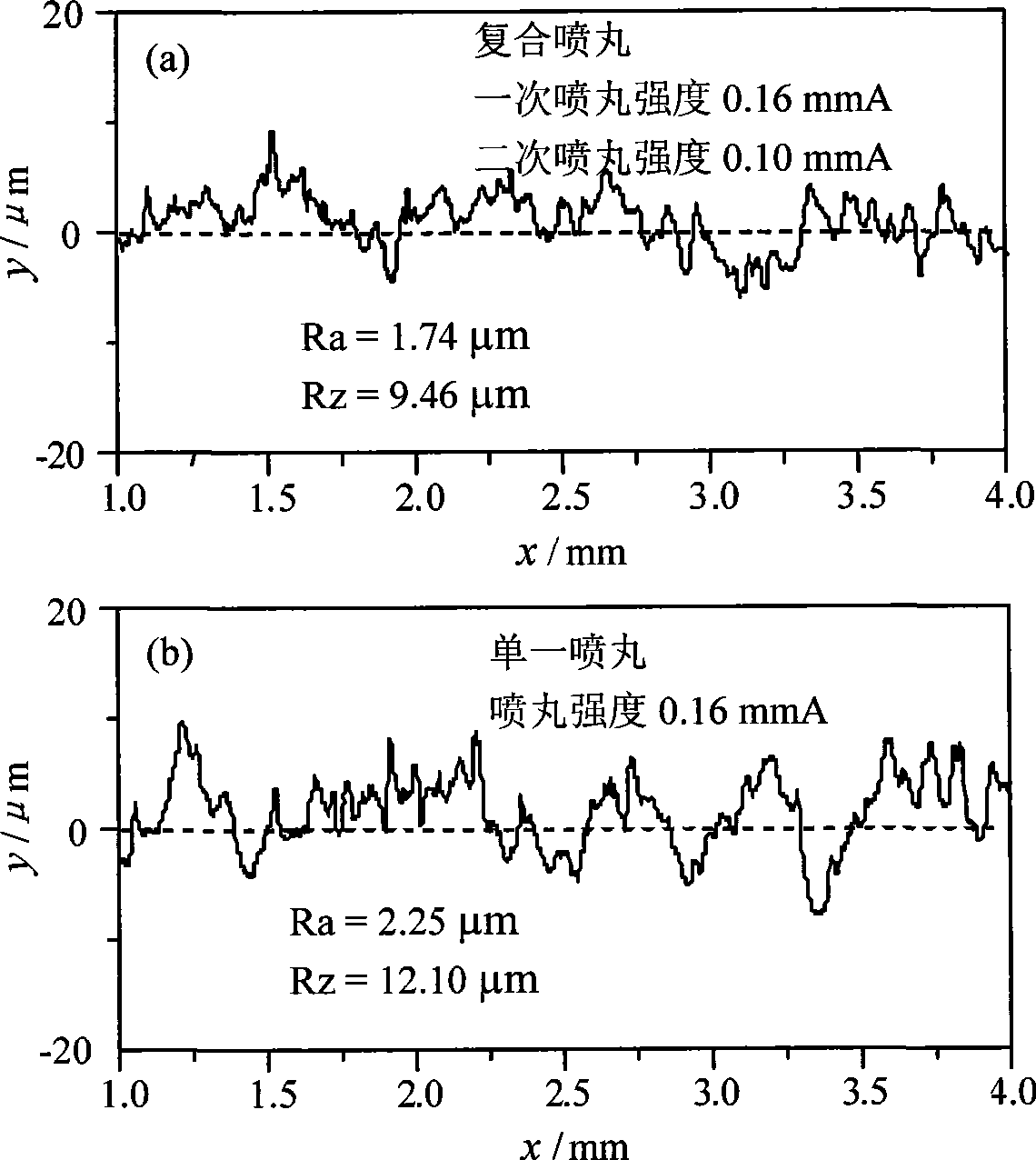

[0018] The experimental material of this embodiment: Inconel750 nickel base alloy, shot peening sample size 70 × 20 × 20mm 3 , numbered 1.

[0019] During implementation, a pneumatic shot blasting machine is used for compound shot peening. Firstly, the No. 1 sample is shot peened once, the shot peening conditions are air pressure 0.4MPa, shot peening intensity 0.16mmA. Then perform secondary shot peening on the basis of the primary shot peening, the shot peening conditions are air pressure 0.3MPa, shot peening intensity 0.10mmA. The projectiles used in the primary shot peening and the secondary shot peening are exactly the same, all of which are stainless steel projectiles with a diameter of 0.3 mm.

Embodiment 2

[0026] The experimental material of this example: 6351Al alloy, the size of shot peening sample is 70×20×20mm 3 , No. 3.

[0027] During implementation, a pneumatic shot blasting machine is used for compound shot peening. Firstly, the No. 3 sample is shot peened once, the shot peening conditions are air pressure 0.6MPa, and shot peening intensity 0.25mmA. Then perform secondary shot peening on the basis of the primary shot peening, the shot peening conditions are air pressure 0.4MPa, shot peening intensity 0.15mmA. The projectiles used in the primary shot peening and the secondary shot peening are exactly the same, all of which are ceramic projectiles with a diameter of 0.2 mm.

[0028] comparative example

[0029] As a comparison, the sample with the same material and sample size as No. 3 sample was selected for single shot peening, numbered No. 4, and the shot peening equipment and shot peening conditions were exactly the same as the single shot peening in compound shot p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com