Method for preparing porous carbon material used for storing energy

A carbon material and pore volume technology, applied in the field of preparation of new porous carbon electrode materials, can solve the problems of long intercalation/deintercalation distance of lithium ions, limited power density improvement space, low power density of lithium ion batteries, etc., to improve energy Density and high power performance, excellent specific energy-specific power performance, effects of improving energy density and high power performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

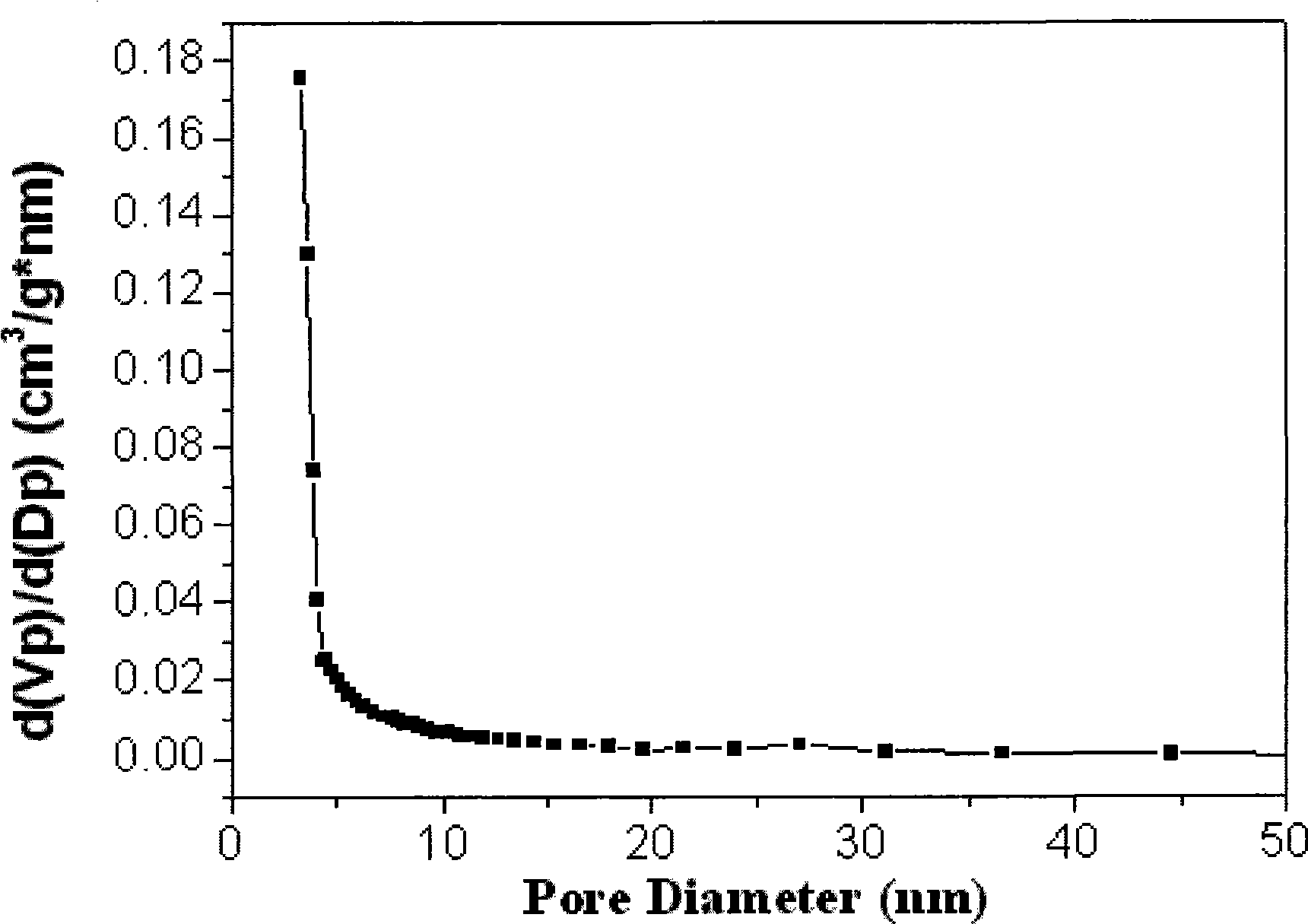

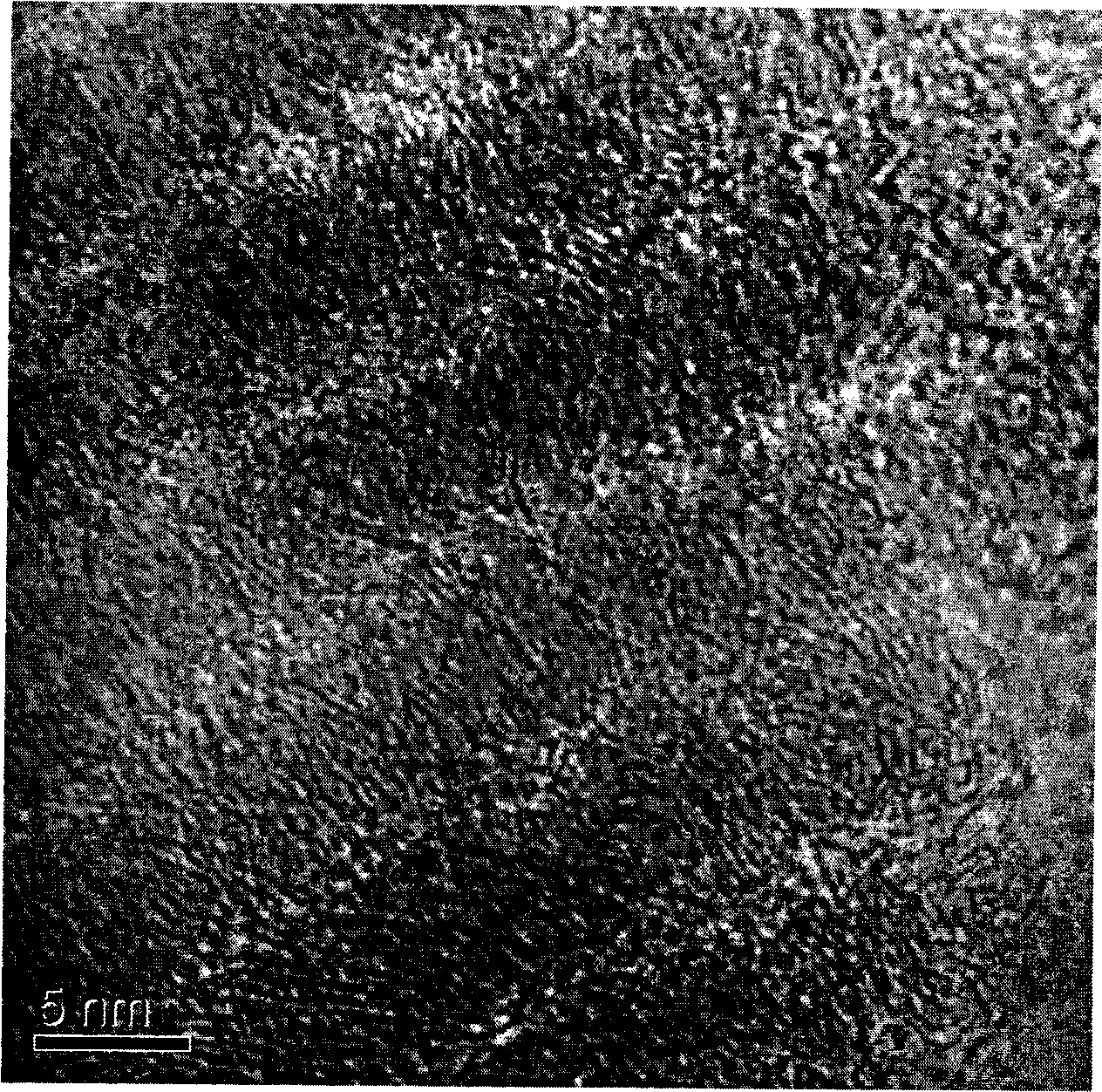

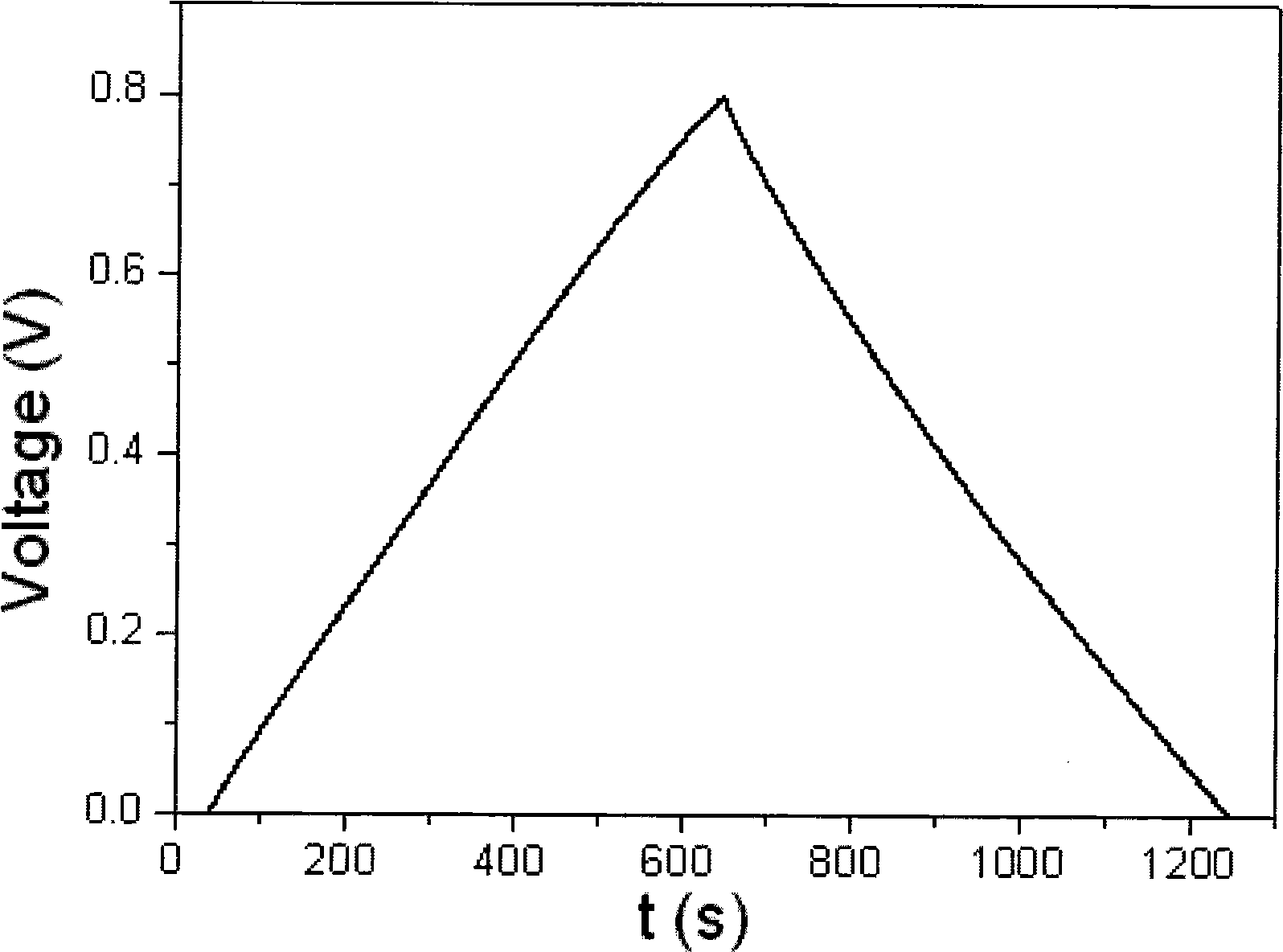

[0027] Take the average pore diameter as 6nm and the specific surface area as 1100m 2 / g of SBA-15 silica template 1g, mesophase pitch 0.4g, fully ground in a mortar, mixed evenly, put into a quartz boat, and then transferred to a tube furnace, 99.99% nitrogen protection, at 5°C / min Raise the temperature of the electric furnace to 280°C and keep it warm for 10 hours, then raise the temperature of the electric furnace to 900°C at a heating rate of 10°C / min, keep it warm for 2 hours, and cool to room temperature under the protection of nitrogen. Use 30% hydrofluoric acid to remove the silica template, filter, wash the filter residue with water until neutral, and dry at 100°C to obtain the product. The specific surface area of the obtained carbon material is 400m 2 / g, the average pore diameter is 4.0nm (as attached to the instructions figure 1 shown), the hole wall has a typical sheet-like stacking structure (as shown in the attached figure 2 shown). As an electrode mater...

Embodiment 2

[0029] Take the average pore diameter as 6nm and the specific surface area as 1100m 2 / g of SBA-15 silica template 1g, mesophase pitch 0.2g, fully ground in a mortar, mixed evenly, put into a quartz boat, and then transferred to a tube furnace, 99.99% nitrogen protection, at 5°C / min Raise the temperature of the electric furnace to 300°C and keep it warm for 8 hours, then raise the temperature of the electric furnace to 900°C at a heating rate of 10°C / min, keep it warm for 1 hour, and cool to room temperature under the protection of nitrogen. Use 30% hydrofluoric acid to remove the silica template, filter, wash the filter residue with water until neutral, and dry at 100°C to obtain the product. The specific surface area of the obtained carbon material is 600m 2 / g, the average pore diameter is 5.0nm, and the pore wall has a typical sheet-like packing structure. As a supercapacitor electrode material, in a 6mol / L KOH solution, the mass specific capacitance of the carbon mate...

Embodiment 3

[0031] Take the average pore diameter as 8nm and the specific surface area as 830m 2 / g of SBA-15 silica template 1g, mesophase pitch 0.4g, fully ground in a mortar, mixed evenly, put into a quartz boat, and then transferred to a tube furnace, 99.99% nitrogen protection, at 5°C / min Raise the temperature of the electric furnace to 320°C and keep it warm for 6 hours, then raise the temperature of the electric furnace to 900°C at a heating rate of 10°C / min, keep it warm for 2 hours, and cool to room temperature under the protection of nitrogen. Use 30% hydrofluoric acid to remove the silica template, filter, wash the filter residue with water until neutral, and dry at 100°C to obtain the product. The specific surface area of the obtained carbon material is 210m 2 / g, the average pore diameter is 6.0nm, and the pore wall has a typical sheet-like packing structure. As a supercapacitor electrode material, in 6mol / L KOH solution, the mass specific capacitance of carbon material r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com