Slurry composition of glass fiber yarn and method for preparing same

A glass fiber yarn and composition technology, which is applied in the field of glass fiber yarn size composition and its preparation, can solve the problems of unstable slurry viscosity, affecting health, and the use of preservatives, etc., and achieve stable slurry viscosity and anti-bending Good degree, increase the effect of toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

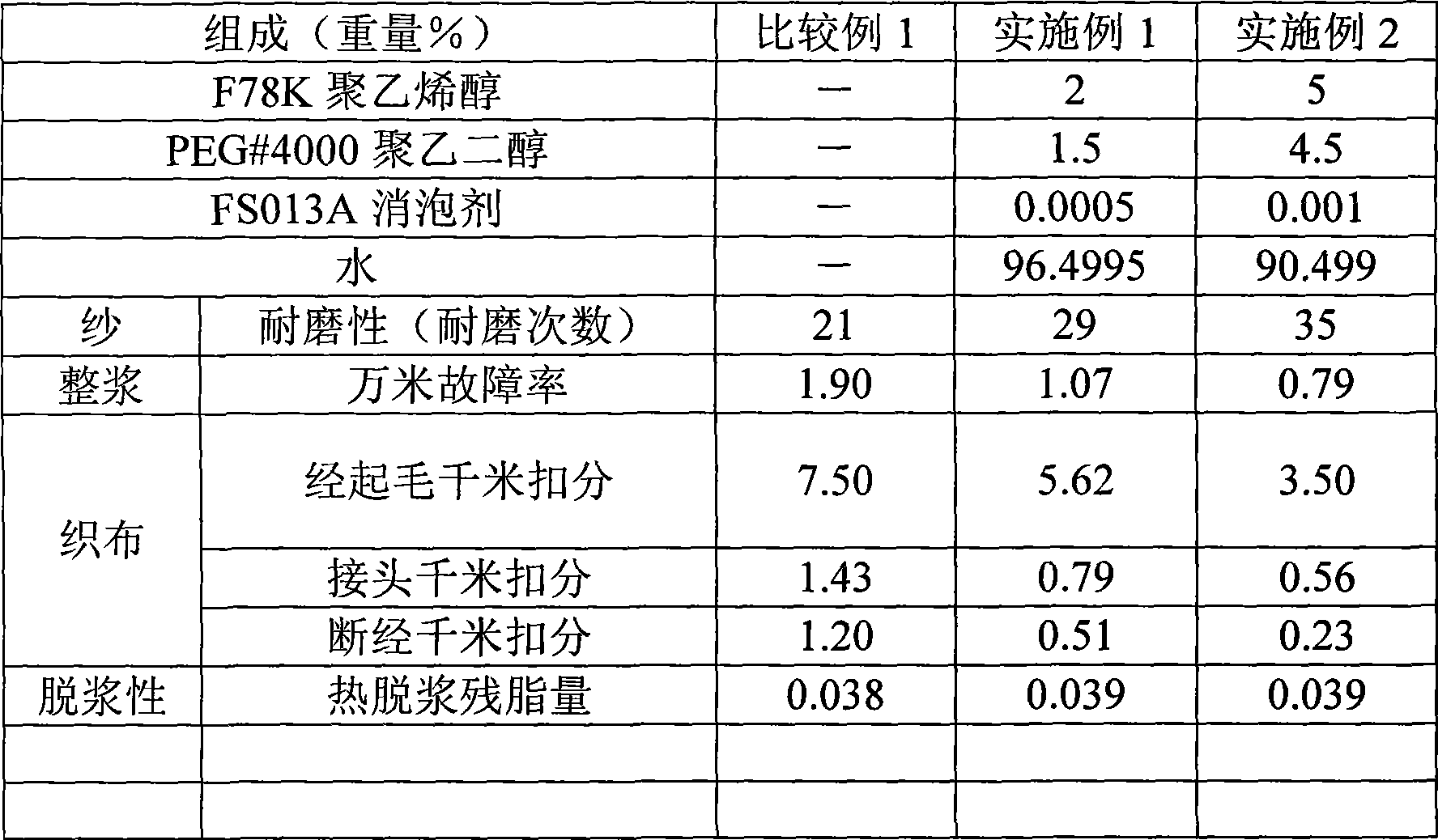

Examples

Embodiment 1

[0027] By weight proportion, formula of the present invention is:

[0028] Polyvinyl alcohol 2%

[0029] Polyethylene glycol 1.5%

[0030] Defoamer 0.0005%

[0031] the rest is water

[0032] The preparation method is as follows: cleaning the slurry kettle, adding soft water into the slurry kettle, starting the mixer, slowly adding polyvinyl alcohol, slowly raising the temperature to 40°C, slowly adding polyethylene glycol, continuing to stir, and slowly raising the temperature to 80°C , keep warm for 30 minutes, add soft water to cool to 60°C, then add the defoamer solution diluted with hot water in advance, stir for 5 minutes, add soft water to adjust and cool to 50°C.

Embodiment 2

[0034] By weight proportion, formula of the present invention is:

[0035] Polyvinyl alcohol 5%

[0036] Polyethylene glycol 4.5%

[0037] Defoamer 0.0015%

[0038] the rest is water

[0039] The preparation method is as follows: cleaning the slurry kettle, adding soft water into the slurry kettle, starting the mixer, slowly adding polyvinyl alcohol, slowly raising the temperature to 60°C, slowly adding polyethylene glycol, continuing to stir, and slowly raising the temperature to 95°C , keep warm for 30 minutes, add soft water to cool to 70°C, then add the defoamer solution diluted with hot water in advance, stir for 5 minutes, add soft water to adjust and cool to 60°C.

Embodiment 3

[0041] By weight proportion, formula of the present invention is:

[0042] Polyvinyl alcohol 3%

[0043] Polyethylene glycol 3%

[0044] Defoamer 0.001%

[0045] the rest is water

[0046] The preparation method is as follows: cleaning the slurry kettle, adding soft water into the slurry kettle, starting the mixer, slowly adding polyvinyl alcohol, slowly raising the temperature to 50°C, slowly adding polyethylene glycol, continuing to stir, and slowly raising the temperature to 85°C , keep warm for 30 minutes, add soft water to cool to 65°C, then add the defoamer solution diluted with hot water in advance, stir for 5 minutes, add soft water to adjust and cool to 54°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com