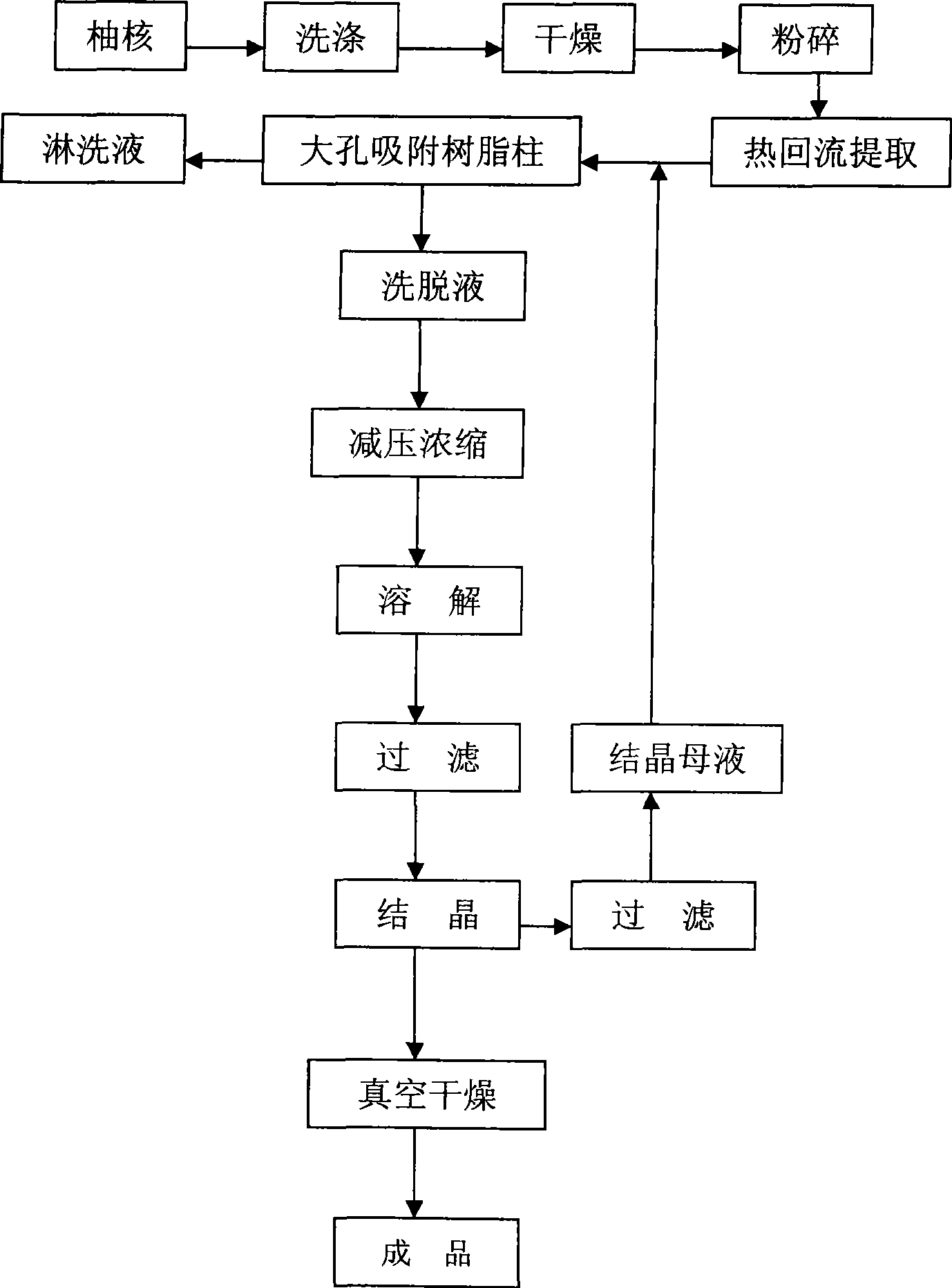

Process for extracting limonin from shaddock kernel

A technology of limonin and pomelo core, which is applied in the field of biochemical separation and purification, can solve the problems of high cost, complicated process and low content, and achieves the effects of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The pomelo cores washed with water were placed in a drying oven at 65°C for 7 hours until the weight was reached, and then crushed to 20 mesh to obtain powder. Weigh 60 grams of pomelo seed powder, wrap it with filter paper, place it in a Soxhlet extractor, and extract 30 times continuously with 300 ml of 60% ethanol aqueous solution at a temperature of 100°C. The extract was diluted to ethanol concentration of 50%, the pH of the extract was 3.0, and flowed through a 50ml HZ816 resin column at a flow rate of 1ml / min. First rinse with 200ml of 40% ethanol aqueous solution at a flow rate of 1ml / min, discard the eluent, then elute with 300ml of 70% ethanol aqueous solution at a flow rate of 1ml / min, collect the eluate, and distill under reduced pressure (0.8bar , 80°C), concentrated to dryness, dissolved in 20ml of dichloromethane, filtered, added 40ml of isopropanol, placed in a refrigerator at 4°C, and slowly stirred for crystallization. The crystallization solution was...

Embodiment 2

[0028] The macroporous adsorption resin HZ816 in Example 1 was replaced with HZ818, and the others were the same as in Example 1 to obtain about 150 mg of limonin finished product with a purity of 92.5%.

Embodiment 3

[0030] Put the washed pomelo cores in a drying oven at 60° C. for 8 hours until the weight is reached, and crush the dried pomelo cores to 40 meshes to obtain powder. Weigh 60 grams, wrap it with filter paper, put it in a Soxhlet extractor, and extract 25 times continuously at a temperature of 110° C. with 300 ml of 70% ethanol aqueous solution. The extract was diluted to an ethanol concentration of 50%, the pH of the extract was 4.0, and flowed through a 50 ml HZ818 resin column at a flow rate of 1 ml / min. Wash with 150ml of 45% ethanol aqueous solution respectively, and the flow rate is 1ml / min. The eluate obtained is discarded, and then eluted with 250ml of 80% ethanol aqueous solution, and the flow rate is 1ml / min. The eluent is collected, and the vacuum distillation (0.8bar , 80°C), concentrated to dryness, dissolved in 20ml of dichloromethane, filtered, added 40ml of isopropanol, placed in a refrigerator at 4°C, and slowly stirred for crystallization. The crystallizatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com