Preparation method of polycarboxylic acids high efficiency water reducer

A high-efficiency water-reducing agent and a polycarboxylic acid-based technology, which is applied in the field of chemical preparation, can solve problems such as the inability to meet the needs of the development of high-performance concrete, and achieve the effects of improving the water-reducing rate, simplifying the production process, and enhancing the slump retention performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

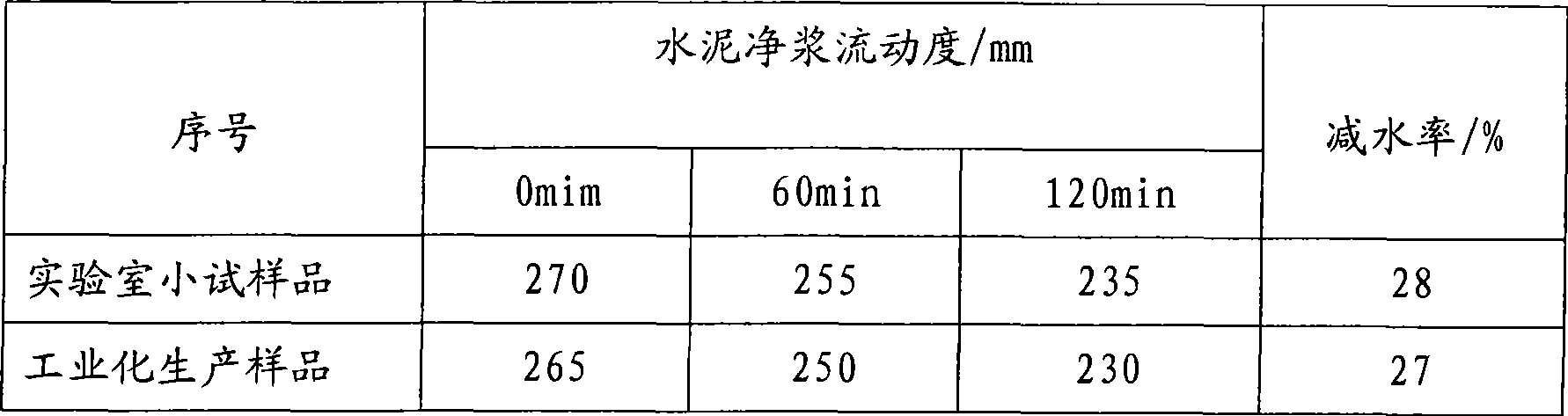

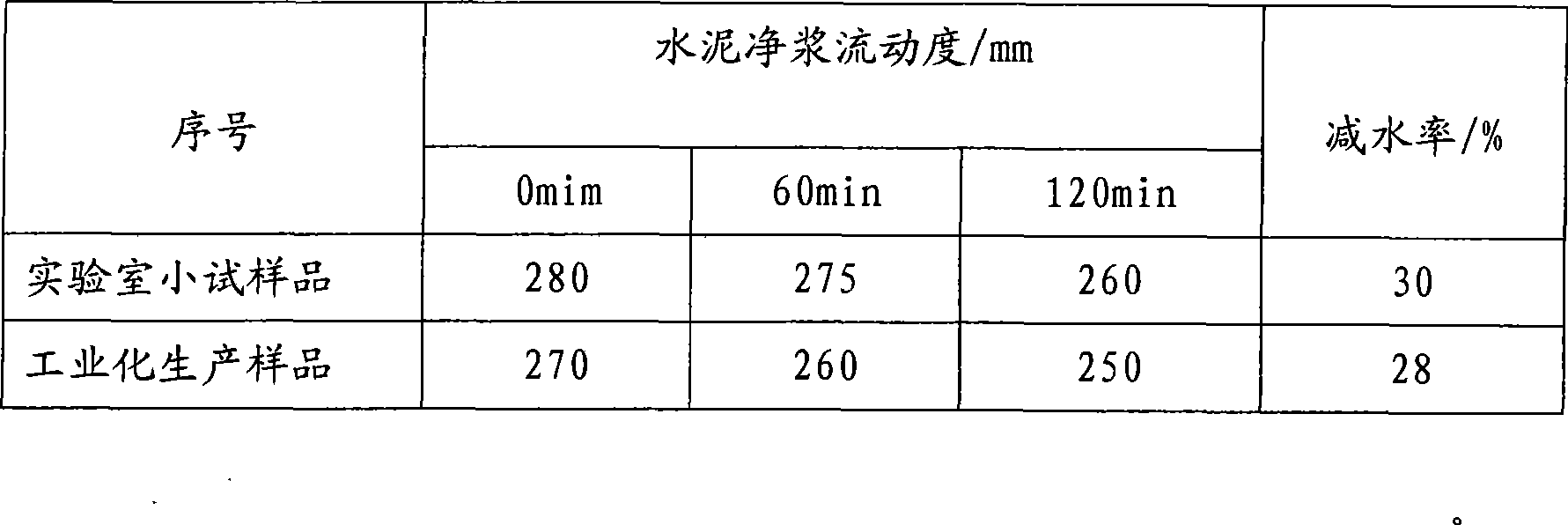

Examples

Embodiment 1

[0017] Preparation of polycarboxylate water reducer:

[0018] The first step, esterification reaction: take 300g (0.1mol) of MPEG (molecular weight 3000), put it into a 1000ml four-necked flask equipped with a breakpoint thermometer, a condenser tube, and a stirrer, and add a resistor when the reaction temperature reaches about 70°C. Polymerizing agent hydroquinone and hydroquinone monomethyl ether each 0.4g, stir evenly, then add 57.6g (0.8mol) of acrylic acid, when the temperature continues to rise to 90°C, add catalyst concentrated sulfuric acid 4.29g, and pass through nitrogen as Water-carrying agent, after reacting at 120°C for 10 hours, the esterified macromer is methoxy polyethylene glycol monomethyl ether acrylate.

[0019] The second step, polymerization reaction: Add appropriate amount of distilled water in a 1000ml four-neck flask equipped with a breakpoint thermometer, a condensing device, and a stirrer, feed nitrogen, and at 85°C, use a constant flow pump to dropw...

Embodiment 2

[0022] The industrialized production of esterification macromonomer of the present invention is as follows:

[0023] (1) Detection of main raw materials: determination of MPEG hydroxyl value, determination of acrylic acid purity

[0024] (2) The operation of production equipment: including the calibration of thermometers, temperature control equipment, and the sealing of pipelines and reactors, etc.

[0025] (3) Weigh 990kg of methoxypolyethylene glycol monomethyl ether (MPEG), put it into the reaction kettle, and when the temperature rises to about 70°C, add the polymerization inhibitor hydroquinone and hydroquinone monomethyl ether respectively. 2.64kg, stir evenly, and add 190.1kg of acrylic acid.

[0026] (4) When the temperature rises to 90°C, add 14.16 kg of concentrated sulfuric acid as a catalyst, and pass nitrogen gas as a water-carrying agent, and react at 120°C for 10 hours to obtain an esterified macromonomer, namely methoxypolyethylene glycol monomethyl ether acr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com