Carbon nano-tube film supported on an aluminum substrate and preparation method thereof

A carbon nanotube film and carbon nanotube technology, applied in the field of carbon nanotube film preparation, can solve problems such as complex operation process, expensive, and limited film uniformity, and achieve the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

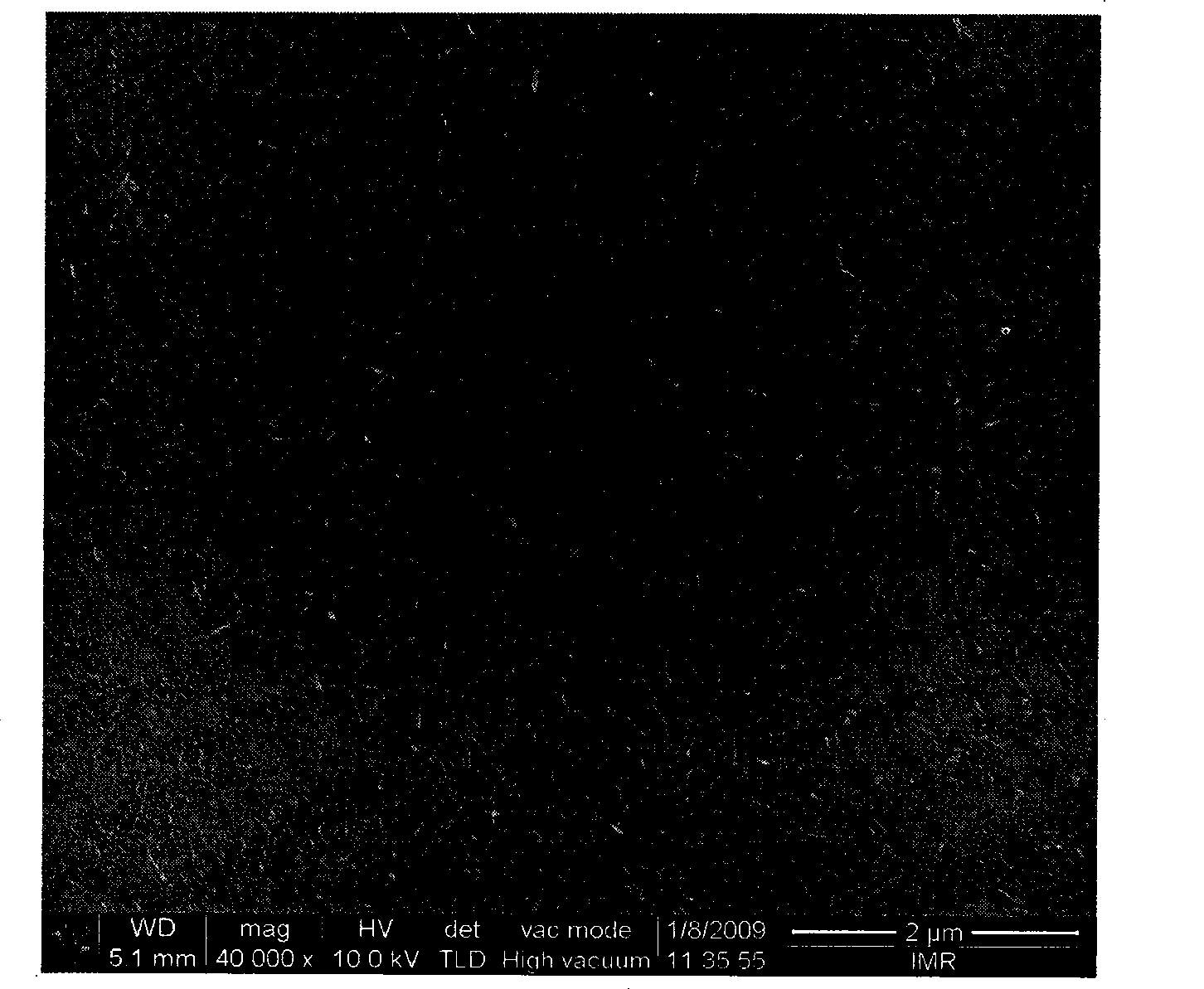

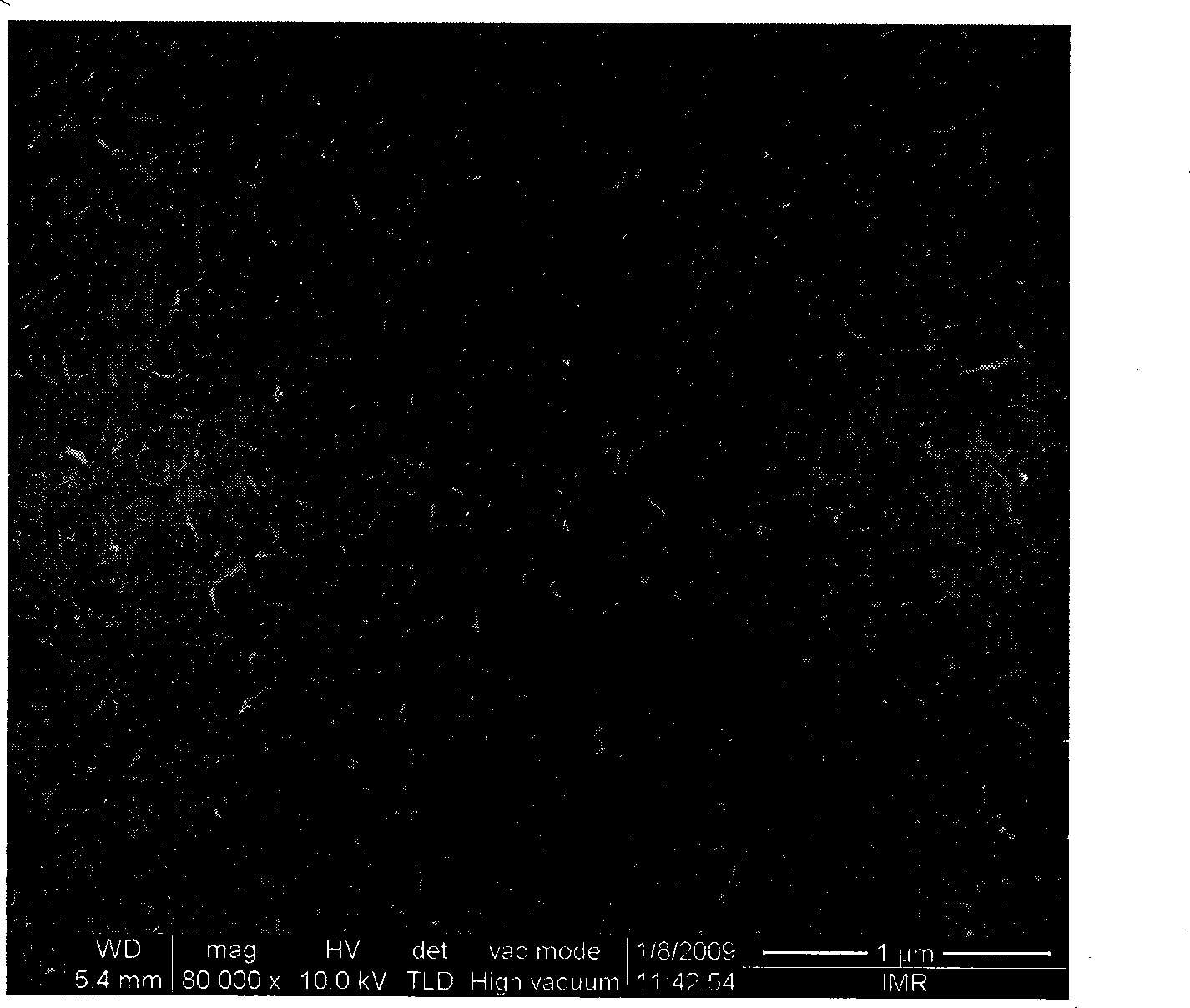

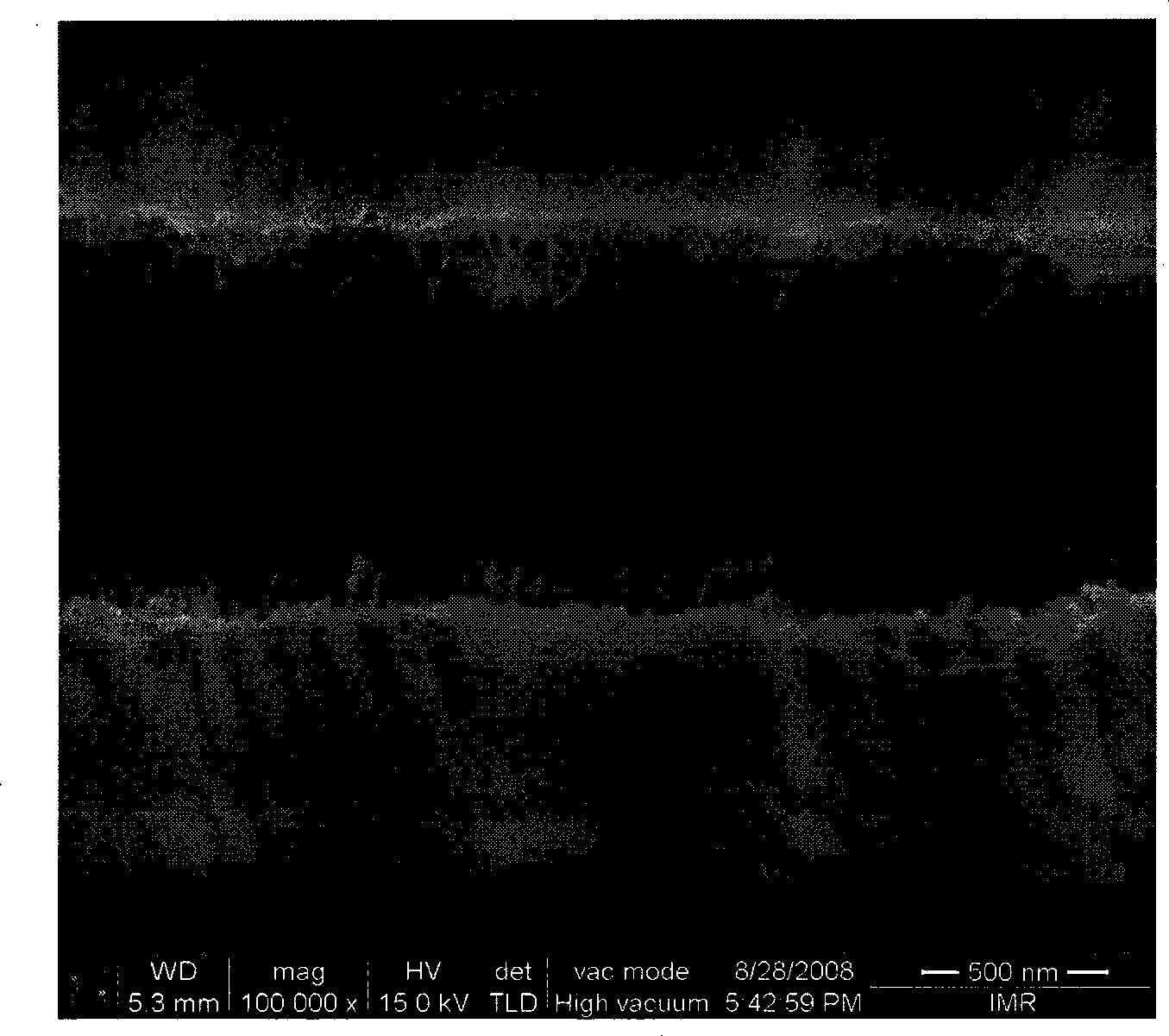

[0017] Take 10mL(T) 60 Single-stranded DNA aqueous solution with a concentration of 0.1 mg / mL, weighed 1 mg of single-walled carbon nanotubes with a diameter of 0.5 nm, placed in the solution, dispersed in an ice-water bath with 10 W ultrasonic for 6 hours, and the temperature was controlled below 4 °C. The obtained mixture was centrifuged at a high speed of 12000 r / min for 60 minutes, the precipitate was filtered off, and the supernatant was taken to obtain a carbon nanotube DNA solution. The aluminum sheet with a purity of 99.99% is cleaned in ethanol, and the natural oxide layer is removed in a 1mol / l sodium hydroxide solution, and electrochemically polished in a perchloric acid ethanol solution (volume ratio 1:3), with a voltage of 12V . Carry out anodic oxidation once in a sulfuric acid solution with a concentration of 5%, the temperature is 5°C, the voltage is 15V, and the time is 1h. After removing the film in a mixed solution of 2% dichromic acid and 6% phosphoric ac...

Embodiment 2

[0019] Take 4mL(T) 5 Single-stranded DNA aqueous solution with a concentration of 0.1 mg / mL, weighed 1 mg of multi-walled carbon nanotubes with a diameter of 20 nm, placed in the solution, dispersed in an ice-water bath with 80 W ultrasonic for 6 hours, and the temperature was controlled below 4 °C. The obtained mixture was centrifuged at a high speed of 12000 r / min for 40 minutes, the precipitate was filtered off, and the supernatant was taken to obtain a carbon nanotube DNA solution. The aluminum substrate was pretreated as described in Example 1. After the aluminum substrate is naturally dried, take the carbon nanotube solution prepared in the above steps. The temperature of the solution is 20°C and the pH value is 5.5, and the aluminum substrate is immersed below the liquid surface. A relatively uniform carbon nanotube film is formed. The carbon nanotube film has good compactness. A single dispersed carbon nanotube can be seen under the scanning electron microscope. The a...

Embodiment 3

[0021] Take 4mL (GT) 10 Single-stranded DNA aqueous solution with a concentration of 10 mg / mL, weighed 1 mg of single-walled carbon nanotubes with a diameter of 2 nm and placed in the solution, dispersed in an ice-water bath with 200 W ultrasonic for 0.5 hours, and controlled the temperature below 4 °C. The obtained mixture was centrifuged at a high speed of 8000 r / min for 60 minutes, the precipitate was filtered off, and the supernatant was taken to obtain a carbon nanotube DNA solution. The aluminum sheet with a purity of 99.99% is cleaned in ethanol, and the natural oxide layer is removed in a 1mol / l sodium hydroxide solution, and electrochemically polished in a perchloric acid ethanol solution (volume ratio 1:3), with a voltage of 12V . An anodic oxidation is carried out once in a sulfuric acid solution with a concentration of 10%, the temperature is 15°C, the voltage is 25V, and the time is 3h. After removing the film in a mixed solution of 2% dichromic acid and 6% phos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

| Sheet resistance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com