Preparation method for metallic aluminum super-hydrophobic surface

A super-hydrophobic surface, metal aluminum technology, applied in the direction of surface coating liquid device, special surface, surface reaction electrolytic coating, etc., can solve the problems of lattice limitation, difficult quality control, cumbersome and other problems, and achieve the reduction of current density Small size, low equipment requirements, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) The aluminum sheet was ultrasonically cleaned with acetone, ethanol, and deionized water for 5 minutes in sequence, and dried naturally for later use.

[0029] (2) Soak the washed aluminum sheet in 1M NaOH solution until a large number of bubbles are formed on the surface for 30 seconds, and then soak it in 5M HCl solution for 5 minutes.

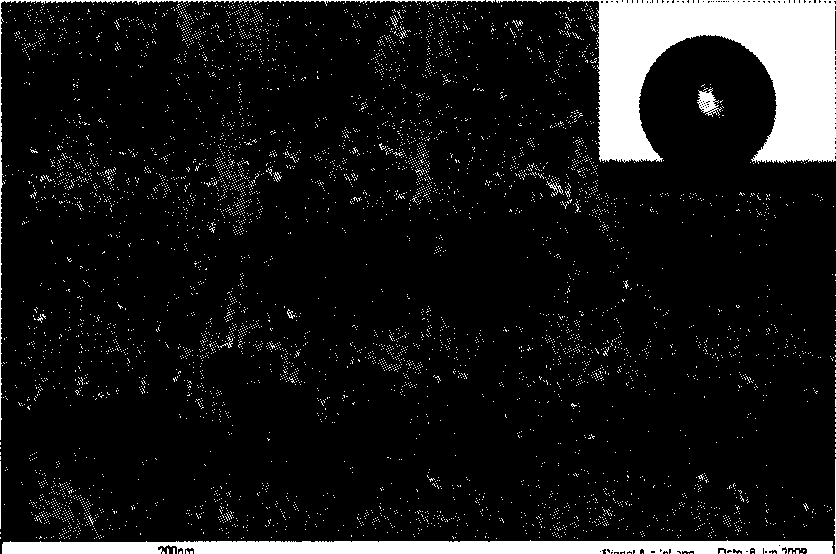

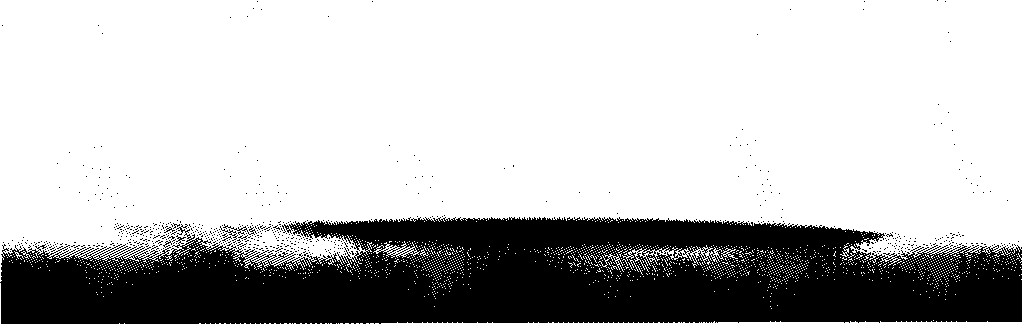

[0030] (3) With the platinum sheet as the cathode and the aluminum foil as the anode, the areas of the cathode and the anode are equal, placed in parallel and facing each other, at room temperature and electrochemical corrosion solution (5%wt H 3 PO 4 Solution: glycerol=1:1V / V) under magnetic stirring, constant current density 1mA / cm 2 Oxidation for 10min. At this time, the surface has superhydrophilic properties, and the contact angle is almost zero.

[0031] (4) Dip the aluminum sheet in a 1% (fluorosilane: ethanol = 1:99 V / V) fluorosilane ethanol solution at 60°C for 1 hour, take it out and dry it naturally to obtain a super...

Embodiment 2

[0034] (1) The aluminum sheet was ultrasonically cleaned with acetone, ethanol, and deionized water for 5 minutes in sequence, and dried naturally for later use.

[0035] (2) Soak the washed aluminum sheet in 1M NaOH solution for 30s until a large number of bubbles are formed on the surface, and then soak it in 4M HCl solution for 10min.

[0036](3) With two equal-area platinum sheets as cathodes and aluminum foils as anodes, they are placed in parallel and facing each other with a distance of 10 mm. 3 PO 4 Solution: glycerol=2:3V / V) under magnetic stirring, constant current density 3mA / cm 2 Oxidation for 15min. At this time, the surface has superhydrophilic properties, and the contact angle is almost zero.

[0037] (4) Dip the aluminum sheet in 1% (fluorosilane: ethanol = 1:99 V / V) fluorosilane ethanol solution for 12 hours, and then dry it in an oven at 120° C. for 10 minutes to obtain a superhydrophobic surface. The contact angle of water droplets on the aluminum surfac...

Embodiment 3

[0039] (1) The aluminum sheet was ultrasonically cleaned with acetone, ethanol, and deionized water for 5 minutes in sequence, and dried naturally for later use.

[0040] (2) Soak the washed aluminum sheet in 1M NaOH solution for 60s until a large number of bubbles are formed on the surface, and then soak it in 3M HCl solution for 20min.

[0041] (3) With two equal-area platinum sheets as cathodes and aluminum foils as anodes, they are placed in parallel and facing each other with a distance of 10 mm. 3 PO 4 Solution: glycerol=2:3V / V) under magnetic stirring, constant current density 3mA / cm 2 Oxidation for 20min. At this time, the surface has superhydrophilic properties, and the contact angle is almost zero.

[0042] (4) Dip the aluminum sheet in 1% (fluorosilane: ethanol = 1:99 V / V) fluorosilane ethanol solution for 12 hours, and then dry it in an oven at 120° C. for 10 minutes to obtain a superhydrophobic surface. The contact angle of water droplets on the aluminum surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com