Radio frequency filter capable of single chip integration and manufacture method thereof

A radio frequency filter and monolithic integration technology, applied in the coupling of optical waveguides, manufacturing microstructure devices, components of TV systems, etc., to reduce substrate loss and simplify the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 - RF low-pass filter can be integrated monolithically

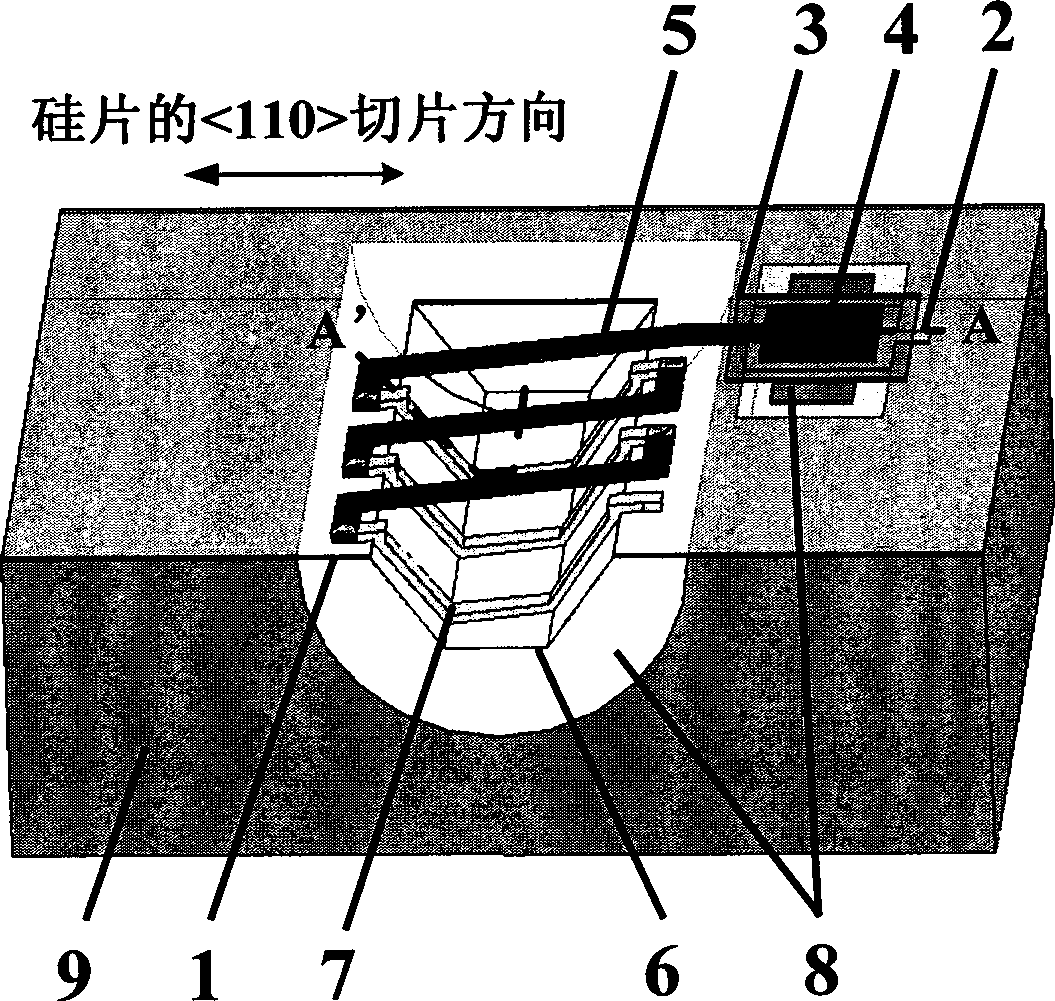

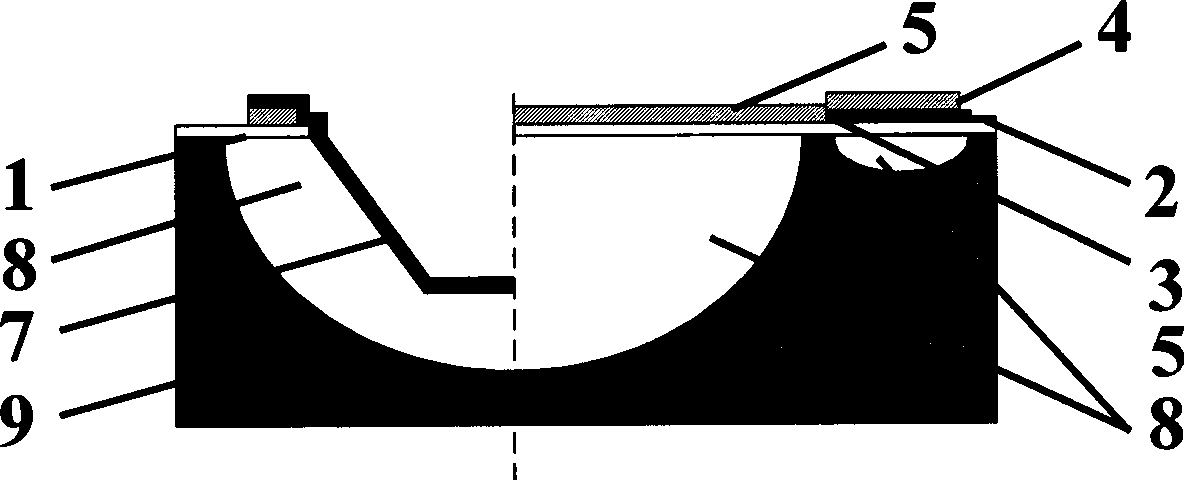

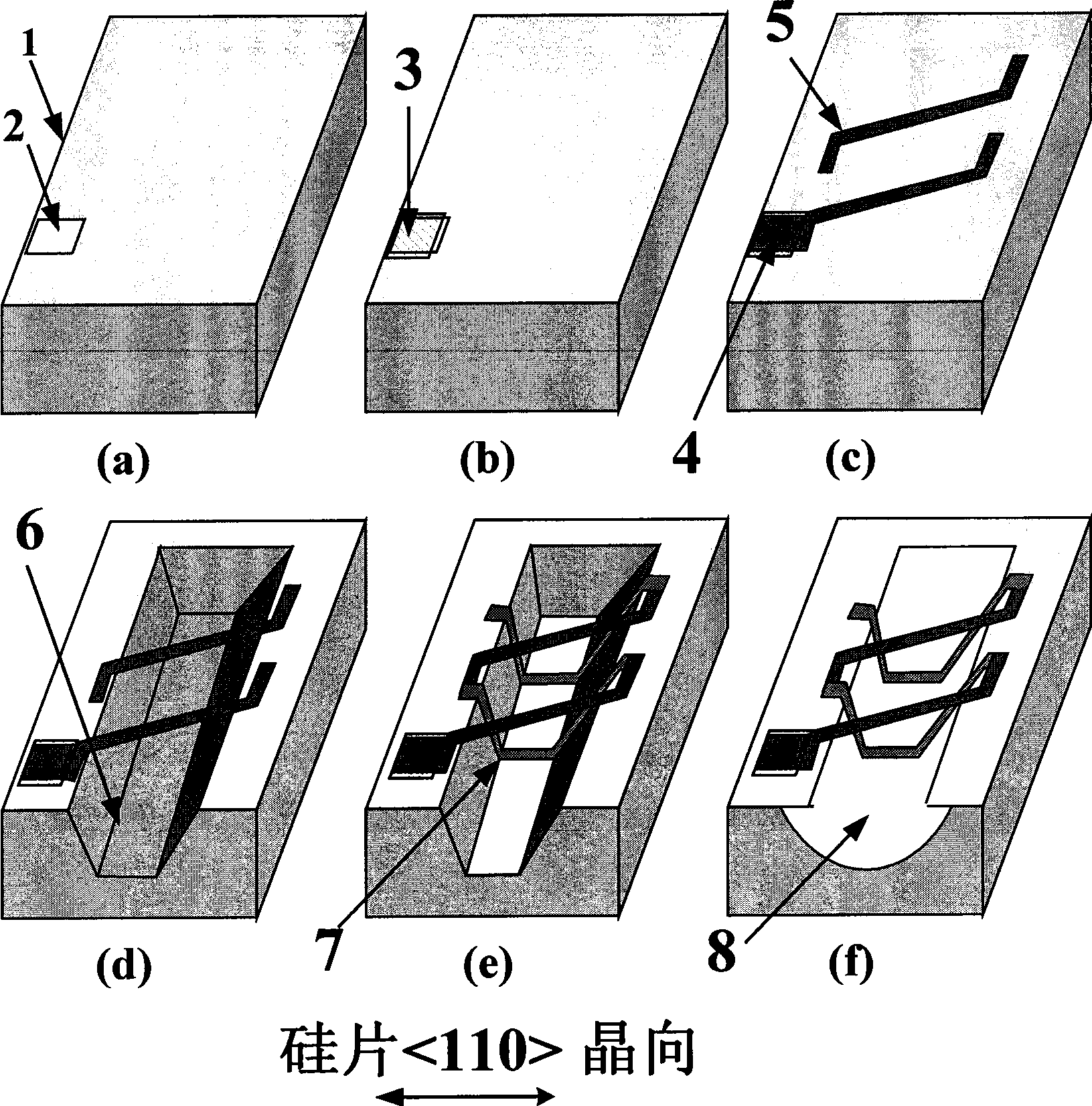

[0031] figure 1 with figure 2 Provide the present invention with a schematic structural view of an on-chip integrated radio frequency low-pass filter, figure 2 for figure 1 Cross section along AA'. A possible production implementation is as follows image 3 As shown in (a)-(f), photolithography was used 5 times in the fabrication. The implementation of this device is not limited to this process flow. In conjunction with the accompanying drawings, the description is as follows:

[0032] 1. Selected material: 4-inch double-polished P-type (100) silicon wafer, resistivity 3-8Ω·cm, thickness 450±10μm, edge cut; plasma-enhanced chemical vapor deposition (PECVD) method Form a silicon dioxide film on the surface of the silicon substrate as a supporting layer after the structure of the inductor and capacitor is released, with a thickness of 1 to 3 microns;

[0033] 2. Sputter a conductive metal laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com