Polysiloxane based in situ polymer blends-compositions, articles and methods of preparation thereof

A technology of polysiloxane and polymer, applied in the field of in-situ polymer blend based on polysiloxane - its composition, article and preparation, which can solve the problems of hindering use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

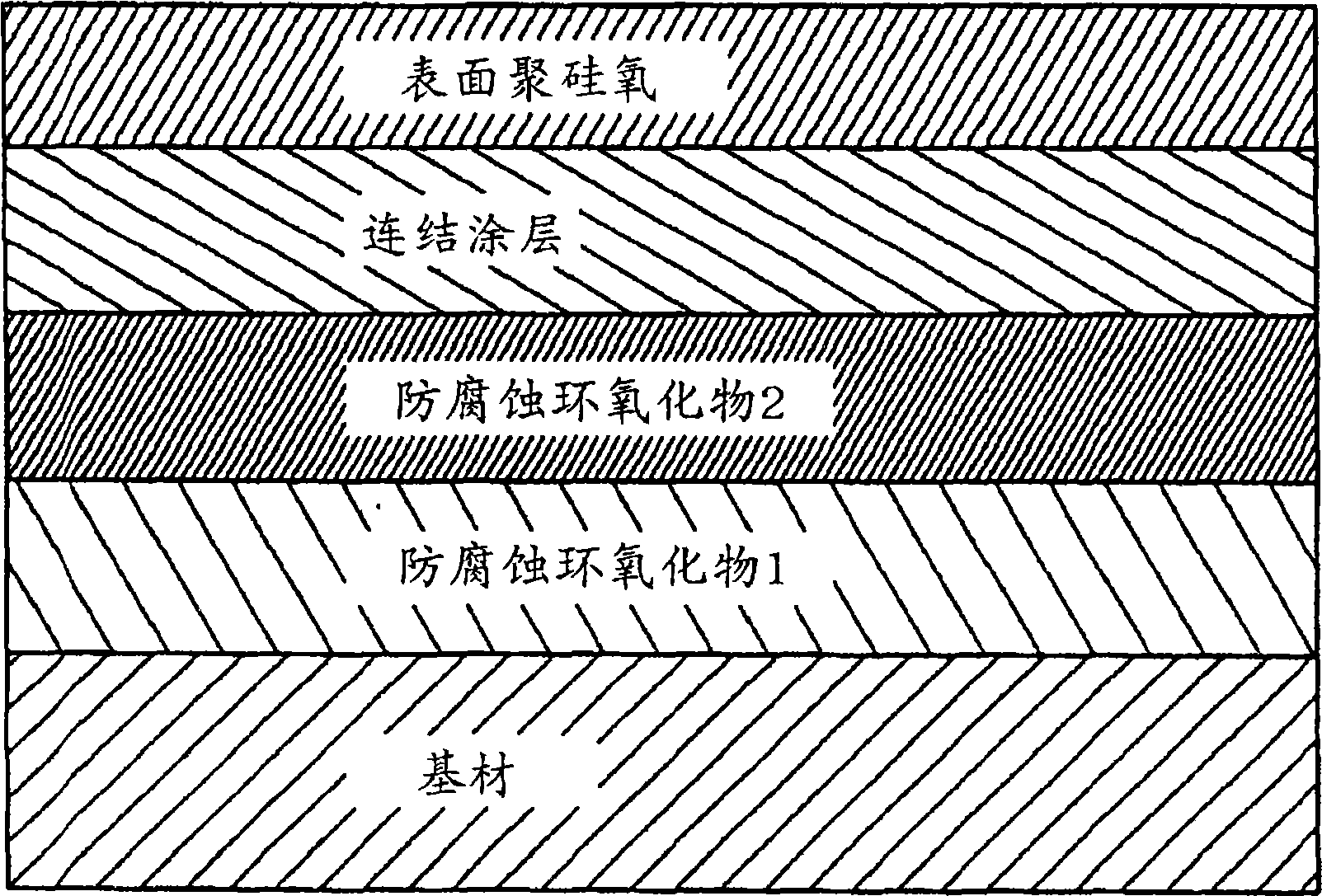

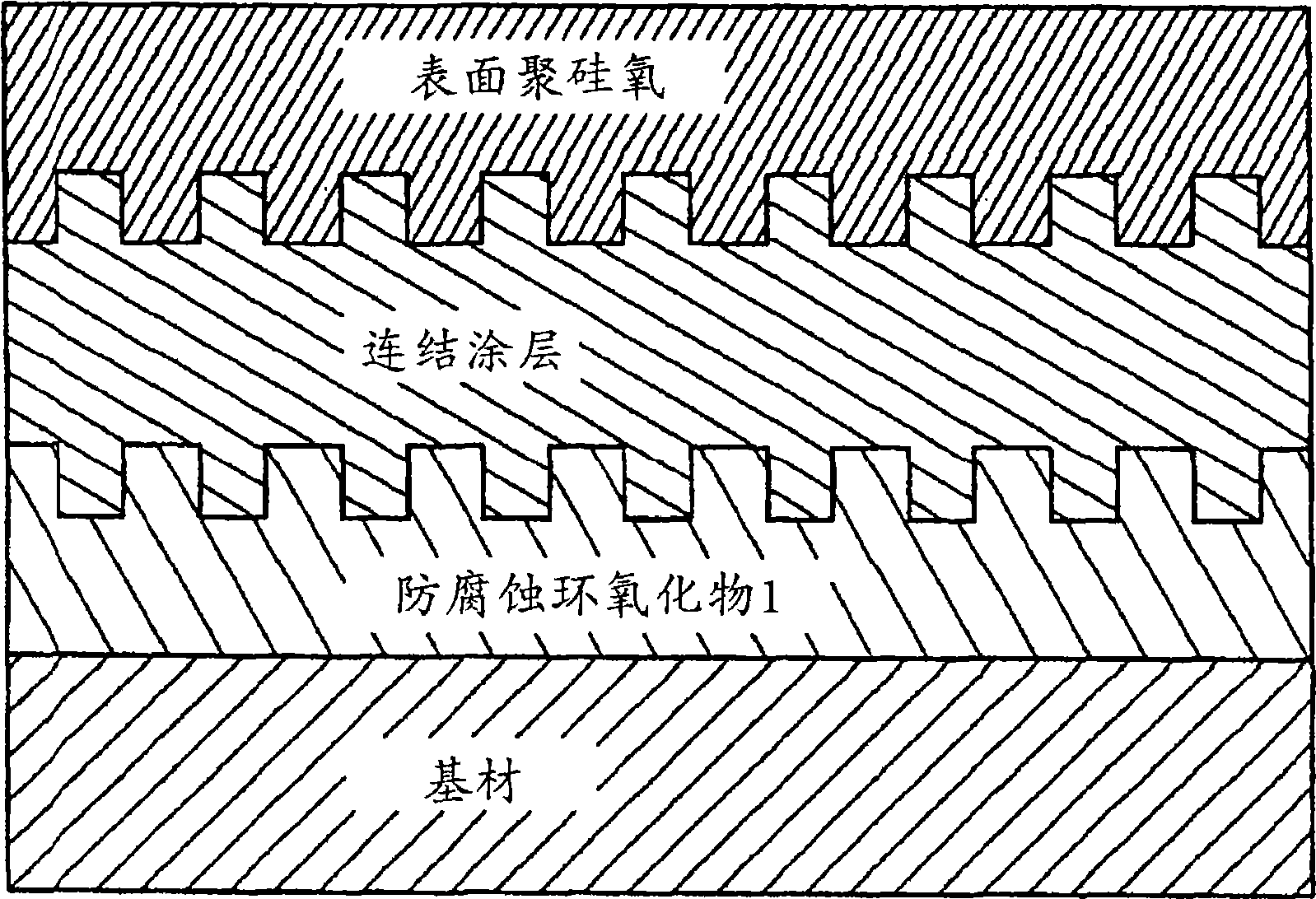

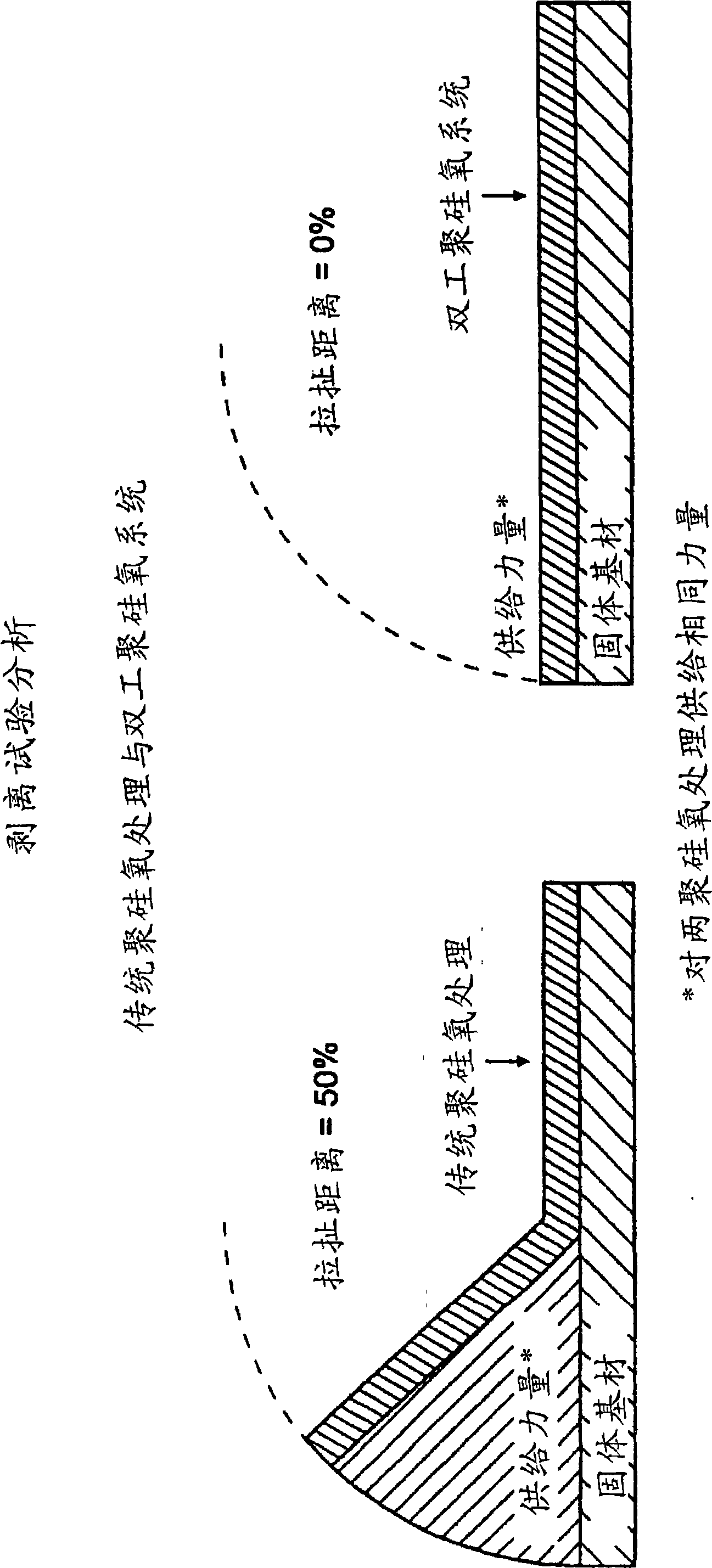

Method used

Image

Examples

Embodiment 1

[0203] Synthesis of polysiloxane-based in situ polymer blends

[0204] The blend reaction was performed in a fume hood using a 3-neck round bottom flask equipped with a condenser and mechanical stirrer and continuously purged with nitrogen. For example, 32 ml of hydroxyl-terminated polydimethylsiloxane having a viscosity of 8,000 cSt at 25°C and 0.386 g of benzoyl peroxide were added to the reactor, and the blend was stirred vigorously for 20 minutes. 12.3 ml of styrene and 35.4 ml of n-butyl acrylate were added to the reactor, and the mixture was stirred continuously for 20 minutes. 20 mL of deionized water was added, and the system was stirred for 20 minutes. Then the reactor was immersed in a water bath at a temperature of 100°C. The color turned off-white within 10 minutes, and the color and viscosity continued to increase throughout the reaction period. After 2 to 3 hours the reaction was complete. The condenser was removed for the last 15 minutes to remove most of ...

Embodiment 2

[0206] Synthesis of polysiloxane-based in situ polymer blends

[0207] The reaction was carried out as before, but using 32 ml of hydroxyl-terminated polysiloxane having a viscosity of 20,000 cSt at 25° C. and 18.5 ml of styrene, 52.6 ml of n-butyl acrylate, 0.836 g of benzoyl peroxide and 20 ml of deionized water. Examples 1 and 2 can be performed in various solvents, including but not limited to toluene, ether, tetrahydrofuran (THF), benzene, methylene chloride, and hexanes. The viscosity of polysiloxanes can range from about 10 to about 100 cSt at 25°C, from about 2,000 to about 8,000 cSt at 25°C and from about 10,000 to about 50,000 cSt at 25°C scope. In a specific embodiment, the polysiloxane has a viscosity of 3,500 cSt. Additionally, initiators include, but are not limited to, benzoyl peroxide, di-tert-butyl peroxide, cumyl hydroperoxide, t-butyl hydroperoxide, AIBN, azo-bis-alkylnitriles, and Di-tert-butyl peroxide.

Embodiment 3

[0209] Exemplary tie coat and top coat formulations

[0210] Exemplary formulations of the tie coat and top coat described herein are shown in Table 2 below, but are not limiting. In each coating, the material was divided into two parts (A and B) before mixing.

[0211] Table 2: Tie coat and top coat formulations (Formulations A and B are expressed in metric units)

[0212] link coating

[0213] A+B top coat Element 1000ml 500ml 250ml 100ml A RTV-11 766.871 383.436 191.718 76.687 SF-1147 92.025 46.012 23.006 9.202

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com