Numerical control horizontal machine tool

A machine tool and horizontal technology, applied in the field of CNC horizontal machine tools for needle rollers of textile machines, can solve the problems that machine tools cannot perform automatic processing, achieve low power consumption, reduce power, and improve the indexing accuracy of workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

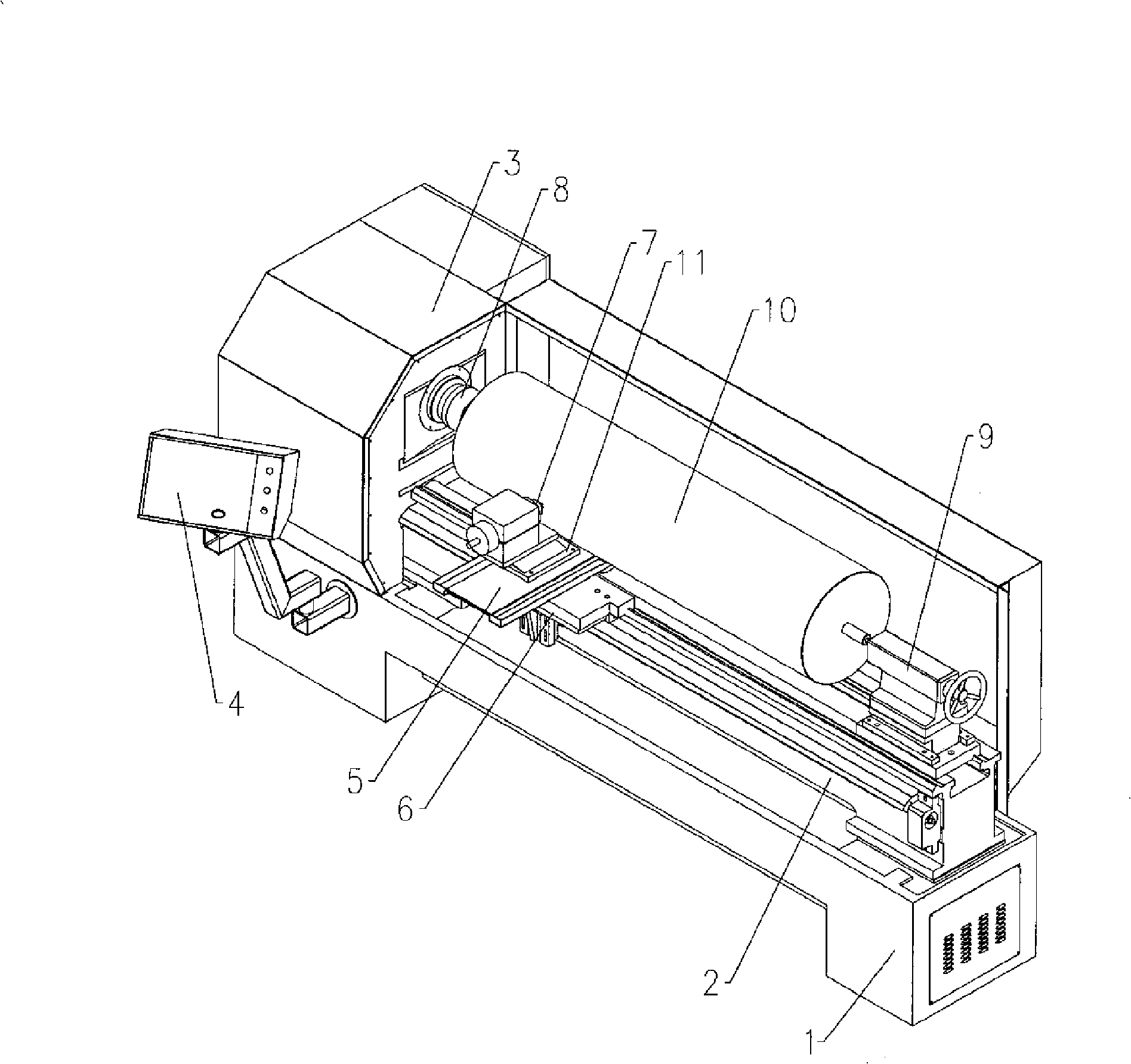

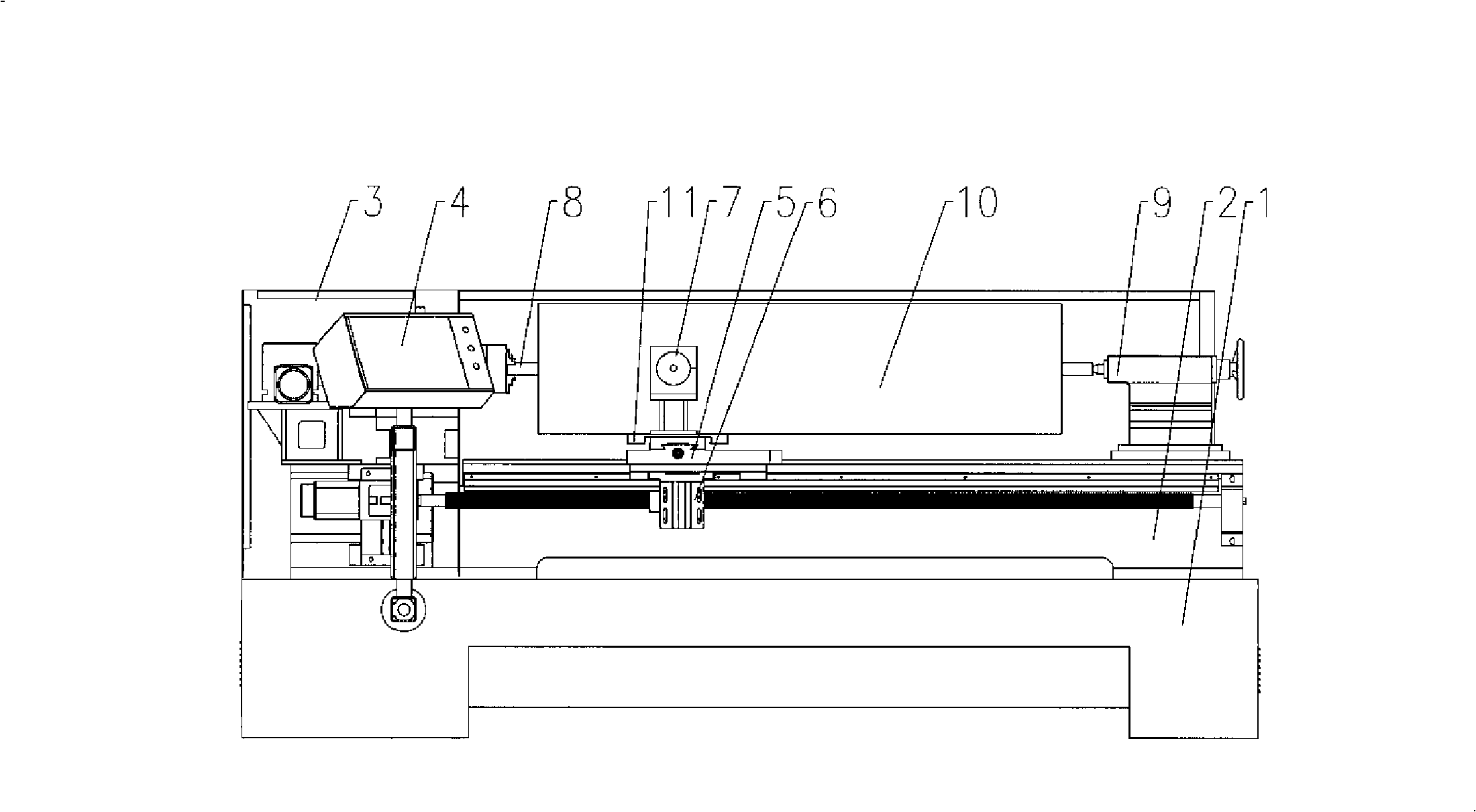

[0011] combine figure 1 , figure 2 Shown: the CNC horizontal machine tool of this embodiment, the machine tool is arranged horizontally, the bed base 1 is provided with a bed 2, the side of the bed is provided with a spindle box 3, and the CNC system 4 controls the work of the servo system. The servo system includes: an X-direction servo system 5 and a Z-direction servo system 6 . The servo system is provided with a high-speed drilling head 7 . The needle roller 10 of the textile machine is positioned between the drive spindle 8 and the tailstock 9. The drive spindle is equipped with a NC indexing head for continuous indexing and position-locking. The maximum processing diameter is 600 mm, and the maximum processing length is 2000 mm. The high-speed drilling head is a graded feed type drilling head, and the machine tool is provided with a water receiving basin 11 and a cooling pipe. The cooling system can ensure sufficient cooling of the high-speed drilling head to achiev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com