Method for realizing mono-disperse modification and optimal orientation array of hypovanadic oxide nano wire

A technology of preferred orientation and nanowires, which is applied in the field of nanomaterials and nanometers, can solve the problems of poor dispersion, affecting the use effect, inability to show surface area effect, volume effect and quantum size effect, etc., to achieve improved performance, good monodispersity and The effect of merit orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

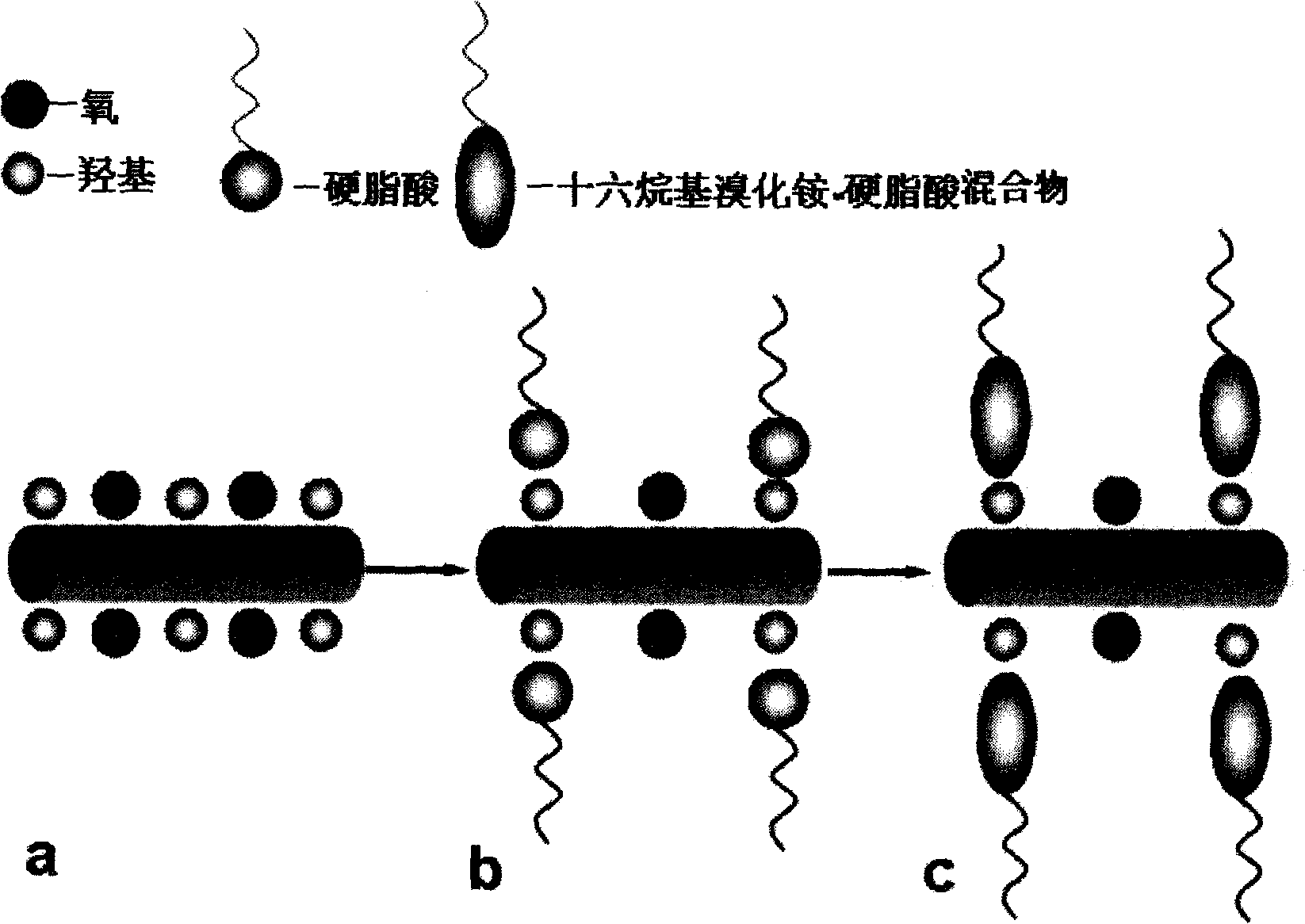

[0020] 1. Measure 50 ml of toluene and transfer it into a 100 ml beaker, add 1 mmol of stearic acid into it and stir vigorously, heat the beaker in a water bath at 90°C, and keep stirring until the stearic acid dissolves or melts; add 0.5 mmol of stearic acid to it. Moore VO 2 Nanowires were centrifuged after stirring for 1 hour, and washed with toluene to remove excess stearic acid to obtain stearic acid-modified VO 2 Nanowires;

[0021] 2. Weigh 10 grams of surfactant CTAB and transfer it to 80 ml of 1 beaker, add 40 ml of cyclohexane and 10 ml of deionized water; take 0.1 mmol of stearic acid-modified VO 2 The nanowires were ultrasonically dispersed in 10 ml of n-butanol for 5 minutes, then all of them were transferred into the above-mentioned cyclohexane solution, and stirred vigorously to obtain a black, clear and translucent microemulsion, which was centrifuged after continuous stirring for 2 hours, using a volume ratio of 1: Wash 10 times with 1 isooctane / chloroform m...

Embodiment 2

[0027] 1. Measure 40 ml of toluene and transfer it into a 100 ml beaker, add 0.8 mmol of stearic acid into it and stir vigorously, heat the beaker in a water bath at 70°C, and keep stirring until the stearic acid dissolves or melts; add 0.4 mmol of stearic acid to it. Moore VO 2 Nanowires, centrifuged after stirring for 0.5 hours, washed with toluene to remove excess stearic acid, and obtained stearic acid-modified VO 2 Nanowires;

[0028] 2. Weigh 8 grams of surfactant CTAB and transfer it to an 80-ml beaker, add 40 ml of cyclohexane and 10 ml of deionized water; take 0.08 mmol of stearic acid-modified VO 2 The nanowires were ultrasonically dispersed in 8 ml of n-butanol for 5 minutes, then all were transferred into the above-mentioned cyclohexane solution, and stirred vigorously to obtain a black, clear and translucent microemulsion, which was centrifuged after continuous stirring for 1.5 hours. The isooctane / chloroform mixed solvent washes 8 times;

[0029] 3. Treat the ...

Embodiment 3

[0033] 1. Measure 60 ml of toluene and transfer it into a 100 ml beaker, add 1.2 mmol of stearic acid into it and stir vigorously, heat the beaker in a water bath at 80°C, and keep stirring until the stearic acid dissolves or melts; add 0.6 mmol of stearic acid to it. Moore VO 2 Nanowires were centrifuged after stirring for 1.5 hours, and washed with toluene to remove excess stearic acid to obtain stearic acid-modified VO 2 Nanowires;

[0034] 2. Weigh 12 grams of surfactant CTAB and transfer it to an 80-ml beaker, add 40 ml of cyclohexane and 10 ml of deionized water; take 0.12 mmol of stearic acid-modified VO 2 The nanowires were ultrasonically dispersed in 12 ml of n-butanol for 5 minutes, then all of them were transferred into the above-mentioned cyclohexane solution, and stirred vigorously to obtain a clear and translucent microemulsion, which was centrifuged after continuous stirring for 2.5 hours, using a volume ratio of 1:1 The isooctane / chloroform mixed solvent wash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com