Lactobacillus bacteria proliferated culture medium and preparation method thereof

A technology for proliferating culture medium and lactobacilli, applied in the field of lactobacillus proliferation medium and preparation thereof, can solve the problems of lack of quality standards, inconsistent quality, uncontrollable and supervising product quality, etc., so as to reduce production costs and facilitate industrialized production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

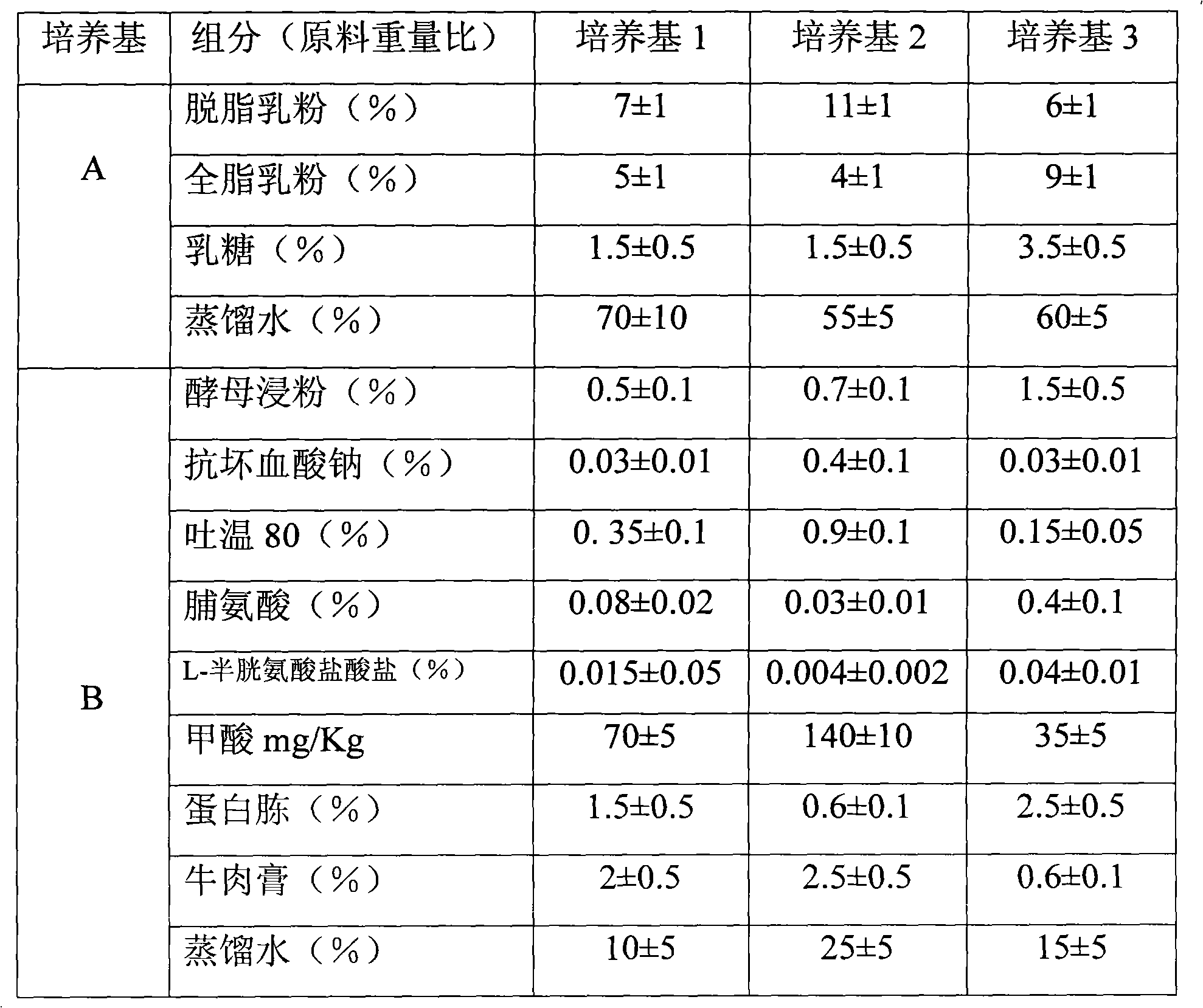

[0016] 1. The formula of lactobacillus proliferation medium is shown in Table 1:

[0017] Table 1 medium formula

[0018]

[0019] 2. Prepare 300g of Lactobacillus Proliferation Medium, using the following steps:

[0020] 1) According to the above-mentioned weight ratio, the components of the above-mentioned medium A and B are dissolved in distilled water respectively;

[0021] 2) Mix medium A and medium B evenly;

[0022] 3) Sterilize medium A and medium B respectively: 110-121°C, 15-30 minutes;

[0023] 4) Cool the medium to below 55-30°C respectively;

[0024] 5) Mix medium A and medium B evenly under aseptic conditions to prepare a lactobacillus proliferation medium.

[0025] 6) The prepared Lactobacillus proliferation medium is stored below 4°C for future use.

Embodiment 2

[0027] The formula of medium 1 in Table 1 was used to prepare a medium for culturing Lactobacillus bulgaricus subspecies for proliferation.

[0028] Cultivation method: 5% inoculation amount, 200 rpm, culture at 42°C, and control the pH value of the fermentation broth to 5.5 with 15% (W / V) sodium hydroxide lye.

[0029] After 6 hours of fermentation, the fermentation was terminated, and the thalline concentration of Lactobacillus was 6.2×10 10 cfu / ml.

Embodiment 3

[0031] The formulation of medium 2 in Table 1 was used to prepare a medium for culturing Lactobacillus bulgaricus subspecies for proliferation.

[0032] Cultivation method: 5% inoculated bacteria, 200rpm, cultured at 42°C, and 15% (W / V) sodium hydroxide lye to control the pH value of the fermentation broth to 5.5

[0033] After 6 hours of fermentation, the fermentation was terminated, and the thalline concentration of Lactobacillus was 5.9×10 10 cfu / ml.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com