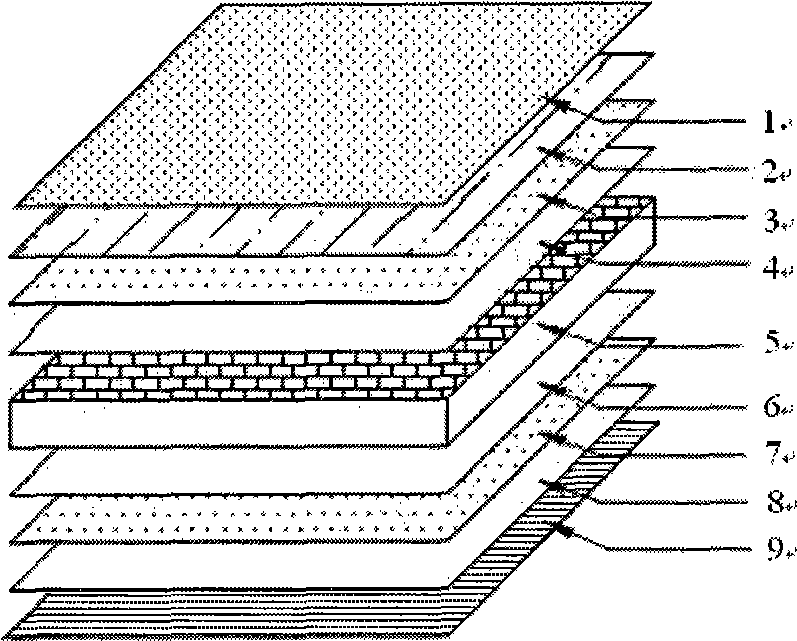

Polyurethane multilayer composite sheet for automotive headliner and processing method thereof

A processing method and polyurethane technology, applied in chemical instruments and methods, lamination, layered products, etc., can solve the problems of skin itching, glass fiber exposure, dust pollution, etc., and achieve the effect of improving production efficiency and accelerating compounding speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

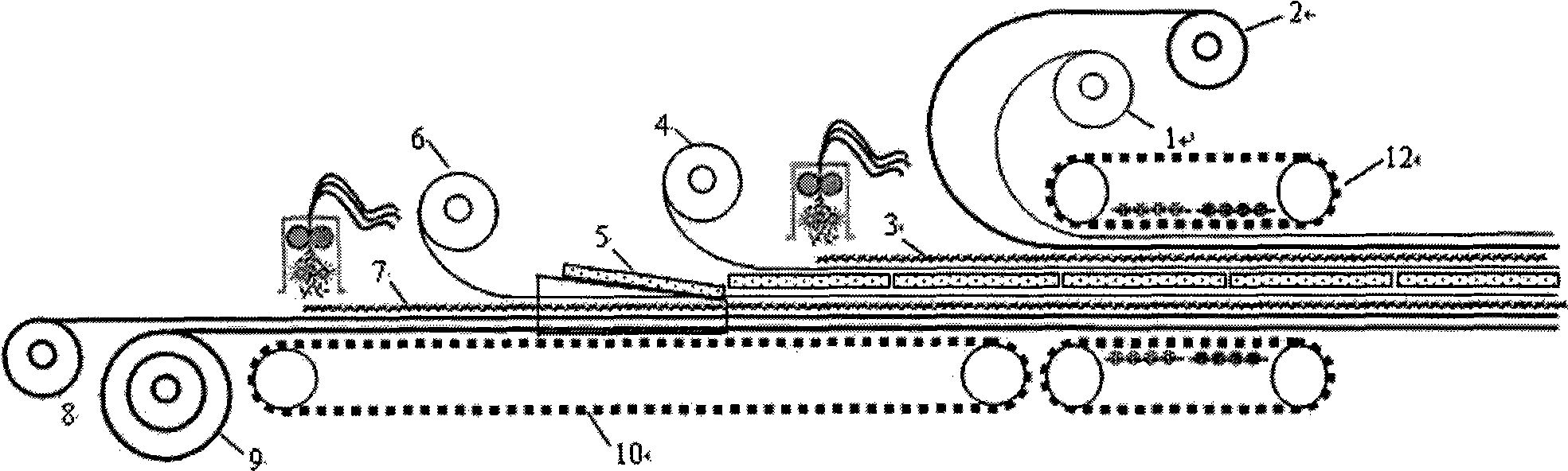

[0028] The processing method of polyurethane multi-layer composite board for automobile roof, the steps are as follows:

[0029] On the workbench of the composite production line, unwind and lay flat 120g / m from bottom to top 2 Hot-bonded non-woven fabric, nano-material modified polypropylene / ethylene-vinyl acetate copolymer reinforced film with a thickness of 120 μm, unwound on the reinforced film, and the flat laying weight is 100g / m 2 Porous, sound-absorbing polyethylene terephthalate fiber mat, and then unwind on the polyethylene terephthalate fiber mat, and lay an adhesive film with a thickness of 120 μm, place a thickness of 8.0mm, and a density of 40Kg / m 3 Polyurethane foam board, and then unroll on the polyurethane foam board, spread an adhesive film with a thickness of 50 μm, unwind on the adhesive film, and lay the weight of 150g / m 2The porous basalt fiber and sisal fiber are mixed with sound-absorbing fiber mat, and then unrolled sequentially on the reinforced fib...

Embodiment 2

[0032] The processing method of polyurethane multi-layer composite board for automobile roof, the steps are as follows:

[0033] On the workbench of the composite production line, unwind and lay flat 60g / m from bottom to top 2 Hot-bonded non-woven fabric, nano-material modified high-density polyethylene reinforced film with a thickness of 100 μm, and the chopped length is 40 mm and the weight is 150 g / m on the reinforced film. 2 flax fiber, and then unroll on the flax fiber, lay an adhesive film with a thickness of 30 μm, place a thickness of 6.0mm, and a density of 35Kg / m 3 The polyurethane foam board, and then unrolled on the polyurethane foam board, the adhesive film with a thickness of 30μm is spread flat, and the chopped length is 40mm and the weight is 150g / m2 on the adhesive film. 2 flax fiber, and then unwind sequentially on the reinforcing fiber, flatten a nano-material modified high-density polyethylene reinforced film with a thickness of 100 μm and a three-layer mo...

Embodiment 3

[0036] The processing method of polyurethane multi-layer composite board for automobile roof, the steps are as follows:

[0037] Unwind and spread 45g / m on the workbench of the composite production line from bottom to top 2 spunlace non-woven fabric, filled modified high-density polyethylene reinforced film with a thickness of 200 μm, unrolled on the reinforced film, and the weight of flat laying is 300g / m 2 The glass fiber felt, and then unwind on the glass fiber felt, and spread the adhesive film with a thickness of 20μm, place a thickness of 5.0mm, and a density of 35Kg / m 3 Polyurethane foam board, and then unrolled on the polyurethane foam board, the adhesive film with a thickness of 30 μm is spread flat, and the chopped length is 60mm and the weight is 300g / m2 on the adhesive film. 2 glass fiber, and then unwind the glass fiber sequentially, flatten the nano-material modified high-density polyethylene reinforced film with a thickness of 200 μm and a grammage of 20g / m 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com