Method for modifying bio-oil through in-situ reduction reaction and esterification reaction

A bio-oil and upgrading technology, which is applied in the petroleum industry, processing hydrocarbon oil, refining hydrocarbon oil, etc., can solve the problems of unsatisfactory hydrogenation effect, unfavorable catalyst thermal stability, and increased energy cost of bio-oil, etc., to achieve Low requirements for reaction equipment, enhanced hydrogenation effect, and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

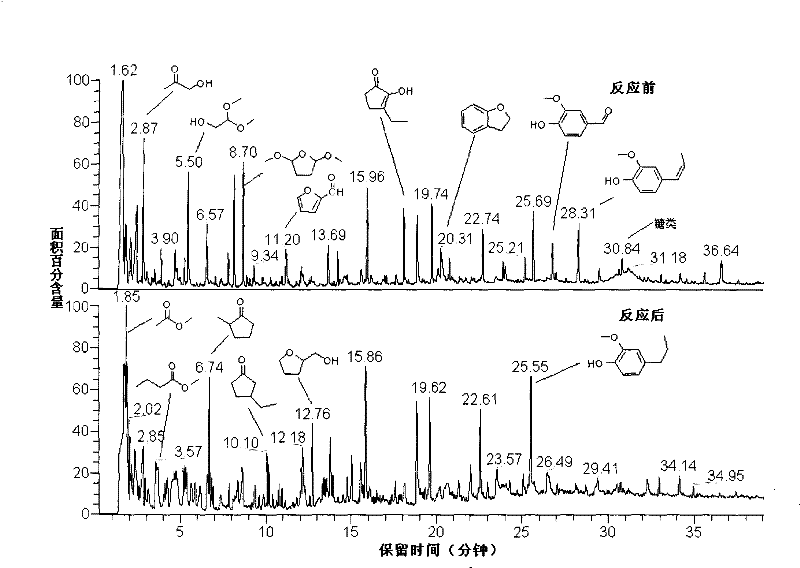

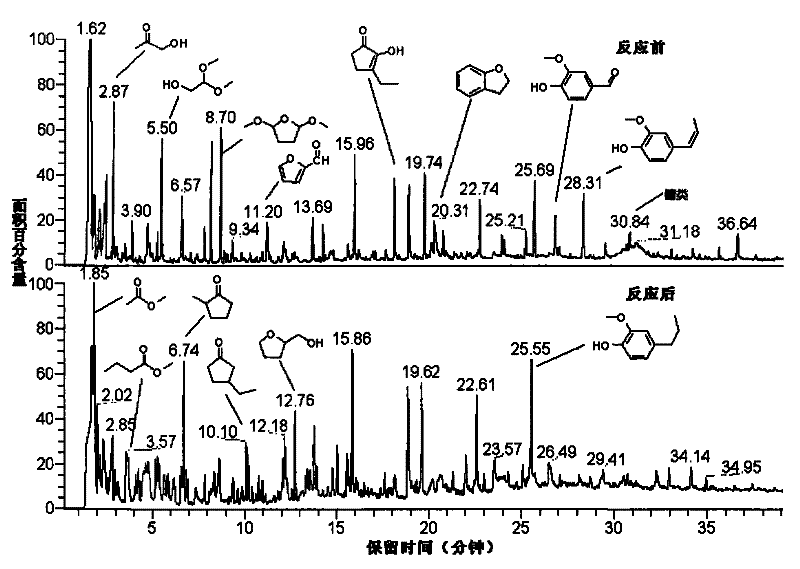

[0038] Weigh 60 parts of bio-oil (with a water content of 30.3wt%) and add it into a 100ml autoclave, then successively add 30 parts of methanol, 10 parts of formic acid and 1 part of metal nickel catalyst. After replacing the air in the kettle three times, start stirring to about 1000 rpm; under temperature-controlled conditions, slowly heat to 200°C and react for 8 hours. After the reaction was finished, the modified bio-oil was collected, and the yield was 89.4%. After testing, its water content is 27.8wt%, and its viscosity is 4.15mm 2 / s, the pH value is 4.35. Its GC-MS test results show that most of the substances containing double bonds and aldehyde groups in the bio-oil are reduced, and organic acids and alcohols form esters. For details, see the attached figure 1 .

Embodiment 2

[0040] Weigh 65 parts (moisture content 30.3wt.%) of bio-oil into a 100ml autoclave, and then successively add 25 parts of ethanol and 5 parts of sodium formate and 2 parts of metal Pd / HZSM-5 (5%) catalyst. After replacing the air in the kettle three times, start stirring to about 1000 rpm; under temperature-controlled conditions, slowly heat to 200°C and react for 7 hours. After the reaction, the modified bio-oil was collected, and the yield was 87.6%. Its water content is 30.4wt%, viscosity is 4.02mm 2 / s, the pH value is 3.74.

Embodiment 3

[0042] The following discusses the comparison between the method of the present invention and other methods in terms of bio-oil modification effect through specific examples.

[0043] Experiment 3-1: Weigh 50 parts of bio-oil (with a water content of 30.3wt.%) and add it to a 100ml autoclave, then add 30 parts of methanol, 10 parts of formic acid and 1 part of Ru / SBA-15 (5 %)catalyst. After replacing the air in the kettle three times, start stirring to about 1000 rpm; under temperature-controlled conditions, slowly heat to 200°C and react for 8 hours. After the reaction was finished, the modified bio-oil was collected, and the yield was 91.3%. Its water content is 28.61wt%, viscosity is 3.84mm 2 / s, the pH value is 4.58. The system has no obvious coking, and the modification effect is better.

[0044] Experiment 3-2: 70 parts of bio-oil (water content 30.3wt.%) was weighed and added to a 100 ml autoclave, and then 15 parts of ethanol and 1 part of metal nickel catalyst wer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com