A process for continuous upgrading of high-temperature slag

A process method and slag technology, which is applied in the direction of electric furnace, furnace, furnace type, etc., can solve the problems that the modifier and slag are difficult to mix evenly, ordinary carbon steel cannot meet daily needs, and the temperature of slag is lowered, etc., to achieve High added value and large-scale utilization, guaranteed modification effect, high temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

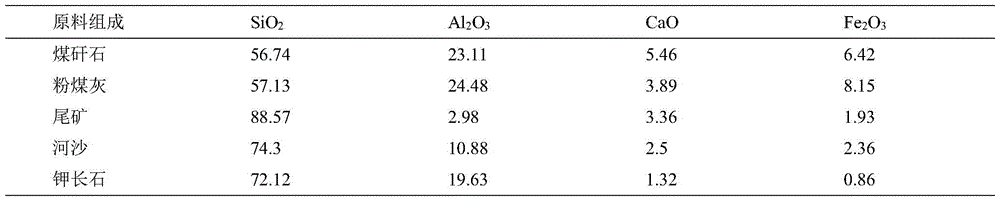

[0028] After crushing and ball milling the raw material of the modifier, the 5-20mm granular material is put into the warehouse for standby. According to the proportion (wt%) of the carbon-containing raw material coal powder and the high-silicon-aluminum raw material potassium feldspar and fly ash (wt%) is 10, 20 Mix the ingredients with 70, then transport the modifier to the electric furnace plant, and add the modifier to the powder conveying silo by driving.

[0029] The effective amount of slag discharged from the electric furnace is about 8 tons. After the electric furnace starts to discharge slag, according to the mass ratio of molten electric furnace slag to modifier is about 2, the modifier in the silo can be continuously fed through the screw conveyor, so that the modifier and molten slag are discharged into the slag at the same time in the bag. The discharge time of electric furnace slag is about 45 minutes. According to this, the discharge stage of slag can be divided...

Embodiment example 2

[0032] After crushing and ball milling the raw material of the modifier, the 5-20mm granular material is put into the warehouse for later use, and the proportion (wt%) of the high-silicon-aluminum raw material river sand and tailings is 30 and 70, and the ingredients are mixed, and then the modified The modifier is transported to the electric furnace factory, and the modifier is added to the powder conveying silo by driving. The effective amount of slag discharged from the electric furnace is about 8 tons.

[0033] After the electric furnace starts to discharge slag, according to the mass ratio of molten electric furnace slag to modifier is about 4, the modifier in the silo can be continuously fed through the screw conveyor, so that the modifier and molten slag are discharged into the slag at the same time in the bag. The discharge time of electric furnace slag is about 45 minutes. According to this, the discharge stage of slag can be divided into early, middle and late stage...

Embodiment example 3

[0036] After crushing and ball milling the raw material of the modifier, the 5-20mm granular material is put into the warehouse for standby, and the proportion (wt%) of the high-silicon aluminum raw material fly ash, river sand and tailings is 70, 15 and 15 respectively, and the batching is carried out Mix, then transport the modifier to the electric furnace plant, and add the modifier to the powder conveying silo by driving. The effective amount of slag discharged from the electric furnace is about 12 tons.

[0037] After the electric furnace starts to discharge slag, according to the mass ratio of molten electric furnace slag to modifier is about 6, the modifier in the silo can be continuously fed through the screw conveyor, so that the modifier and molten slag are discharged into the slag at the same time in the bag. The discharge time of electric furnace slag is about 45 minutes. According to this, the discharge stage of slag can be divided into early, middle and late sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com