Fibre optic gas detector for fire hazard of coal gab area

A technology for gas detectors and gobs, applied in the direction of color/spectral characteristic measurement, spectrum generation using multiple reflections, spectrum generation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

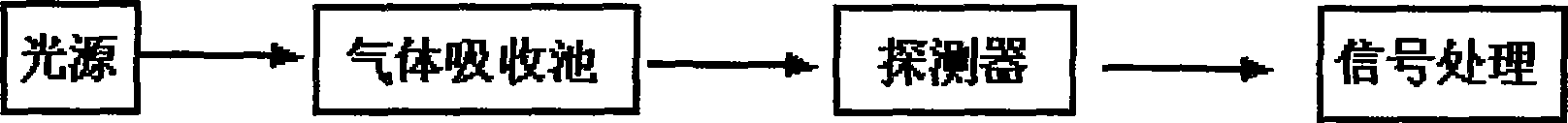

Method used

Image

Examples

Embodiment Construction

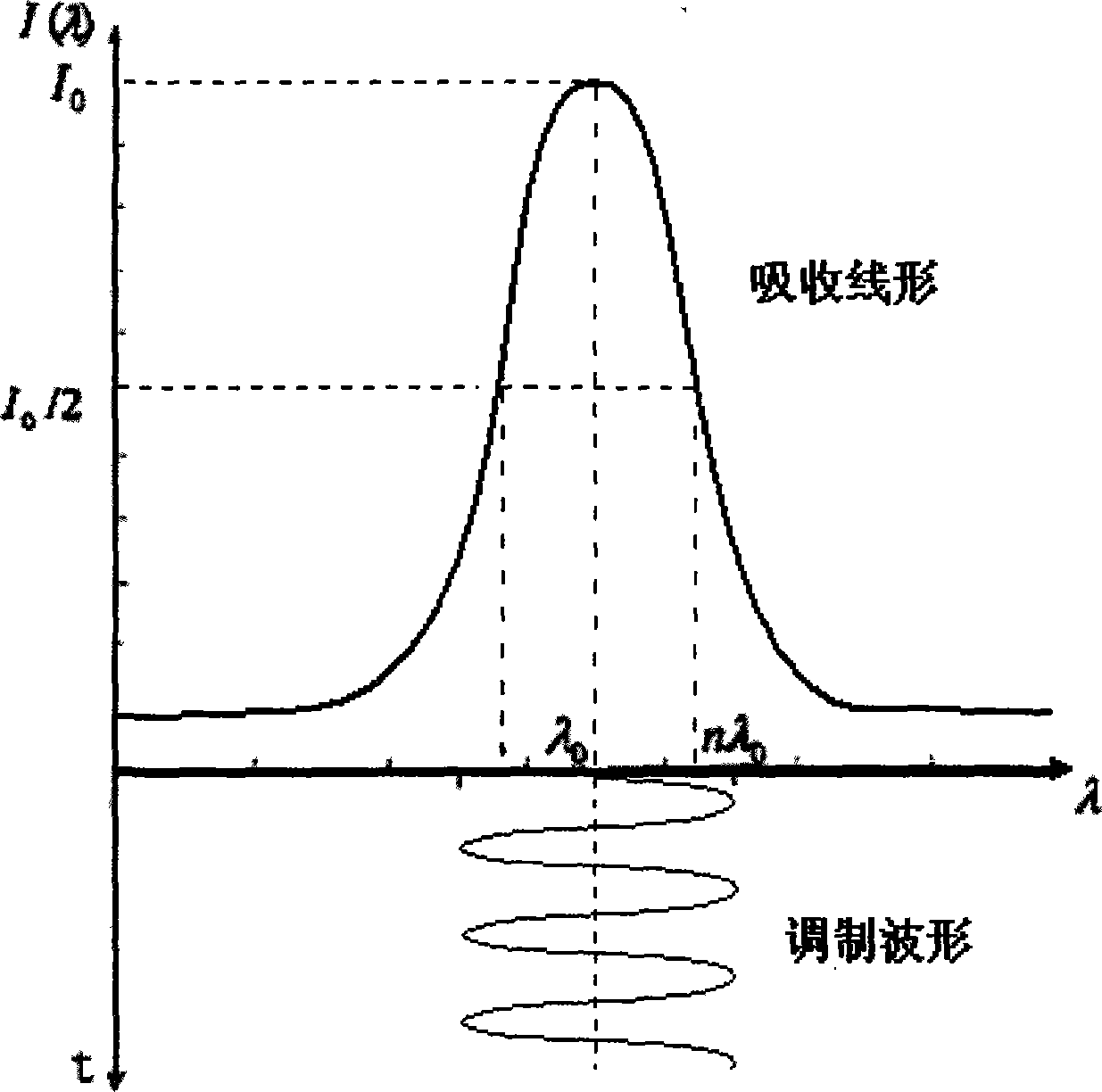

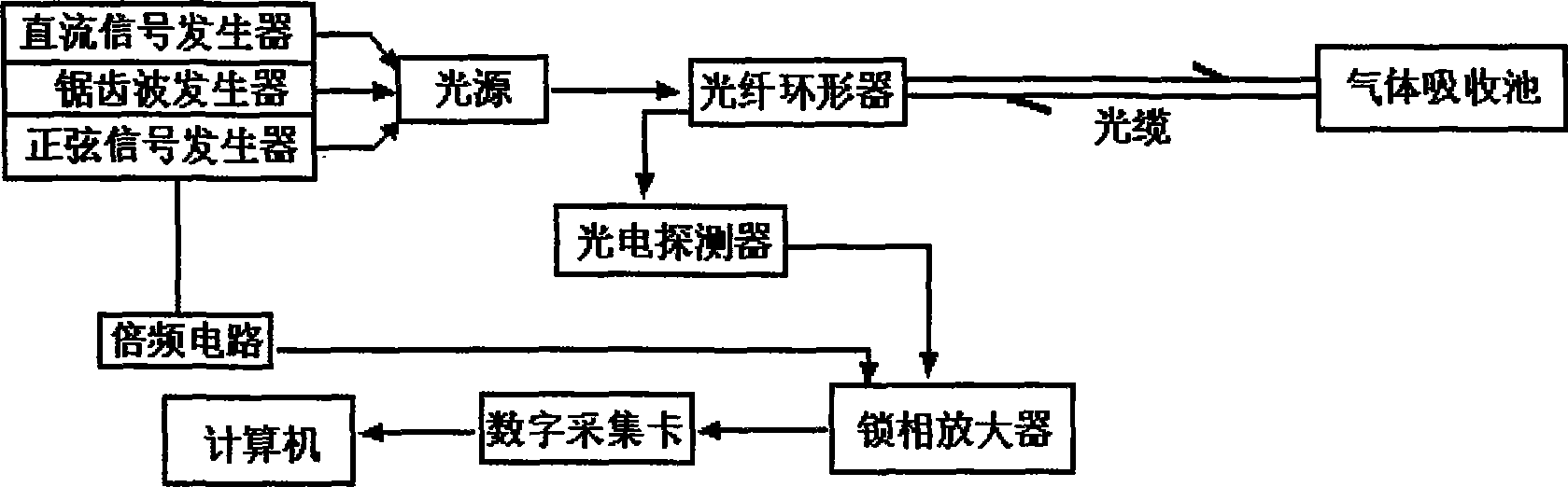

[0070] Such as image 3 As shown in , choose a distributed feedback semiconductor laser with temperature control as the light source; the relationship between the driving current signal and time is as follows Figure 4 As shown, it is the superposition effect of the above three signals. Since the center wavelength of the laser emitted by the laser and the magnitude of the driving current are also approximately linear, the change in the wavelength of light emitted by the driving signal driven by the laser is also the superposition effect of the above three signal waveforms. The sawtooth signal is 100Hz, and the sine signal is 10KHz. The central wavelength of the light source is required to select an appropriate central wavelength according to the corresponding absorption peak position of the gas in Table 1. Different gases require lasers with different central wavelengths; for example, to detect carbon monoxide, we choose 1.567um as the central wavelength of the light source, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com