Diffusion plate for backlight source of liquid crystal display

A liquid crystal display and backlight technology, applied in the fields of instruments, optics, nonlinear optics, etc., can solve the problem of no effective countermeasures for the decline of the life of the diffusion plate, the quality of light diffusion is not ideal, and the optical effects such as haze and brightness are poor. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

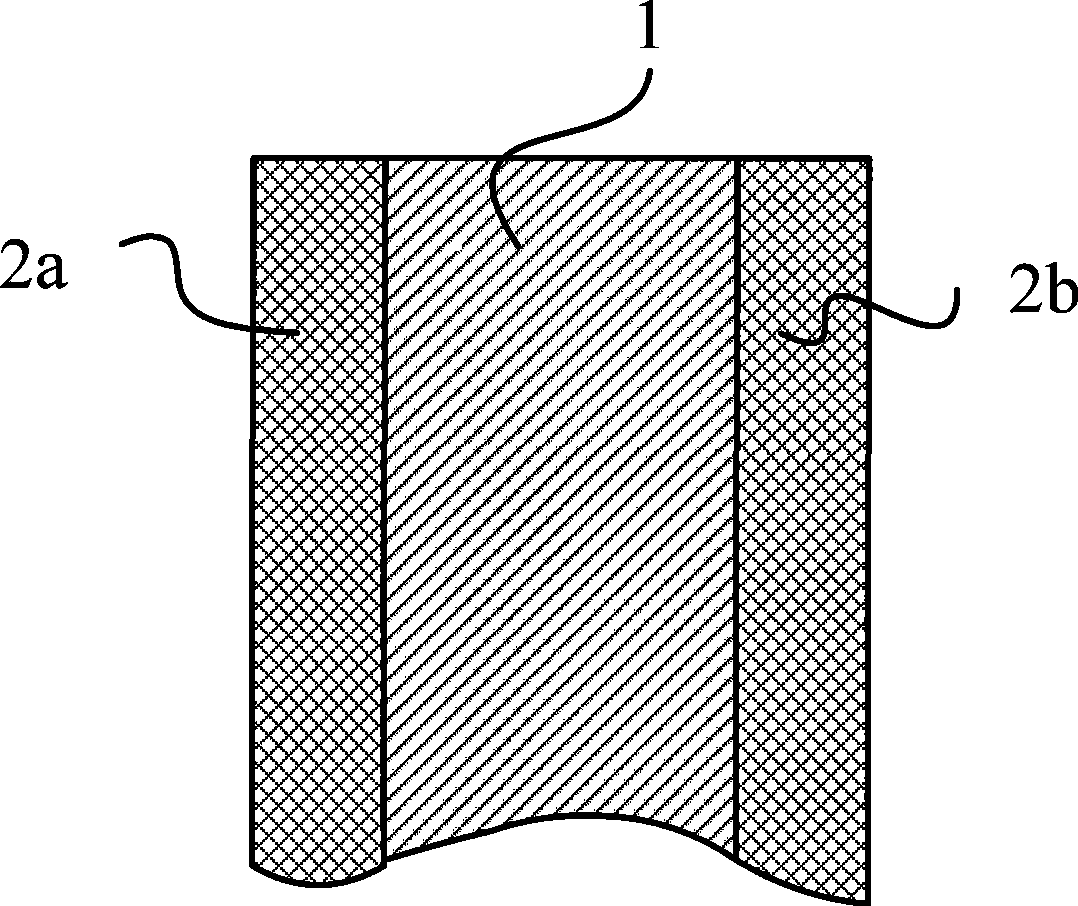

[0021] Such as figure 1 As shown, a diffuser plate for a backlight source of a liquid crystal display is composed of at least a substrate layer 1 and two upper and lower side layers 2a, 2b to form a layered composite structure. The substrate layer 1 is sandwiched between the side layers 2a and 2b. The substrate Layer 1 is a blend layer that uses polystyrene (PS) as the base material and a light diffusing agent, and side layers 2a and 2b are made of polymethyl methacrylate (PMMA) as the base material, light diffusing A blended layer composed of triazole UV absorbers. Moreover, the thickness range of the light diffusion plate is 0.5mm-3mm, and the thicknesses of the side layers 2a and 2b are both 0.04mm-0.06mm.

Embodiment 2

[0024] Such as figure 1 As shown, a diffuser plate for a backlight source of a liquid crystal display is at least a layered composite structure composed of a substrate layer 1 and side layers 2a, 2b. The side layers 2a, 2b are two layers, and the substrate layer 1 is sandwiched therein. The substrate layer 1 is a blend layer made of polystyrene (PS) as the base material and light diffusing agent, and the side layers 2a and 2b are made of polycarbonate (PC) as the base material and light diffusing agent and benzo A blended layer composed of triazole UV absorbers. In order to achieve the optimal use effect, the thickness range of the light diffusion plate is 0.5mm-3mm, and the thickness of the side layers 2a and 2b are both 0.04mm-0.06mm.

[0025] In the above-mentioned second specific embodiment, polystyrene (PS) is used as the base material of the substrate layer 1 , and its low water absorption rate reduces the possibility of deformation of the plate due to the influence of ...

Embodiment 3

[0027] Such as figure 1 As shown, a diffuser plate for a backlight source of a liquid crystal display is at least a layered composite structure composed of a substrate layer 1 and side layers 2a, 2b. The side layers 2a, 2b are two layers, and the substrate layer 1 is sandwiched therein. The substrate layer 1 is a blend layer made of polystyrene (PS) as the base material and light diffusing agent, and the side layers 2a and 2b both use polymethyl methacrylate and styrene copolymer (MS) as the base material Blended layer with light diffusing agent and benzotriazole UV absorber. In order to achieve the best combination of layered composite structures, the thickness range of the light diffusion plate is 0.5mm-3mm, and the thickness of the side layers 2a and 2b are both 0.04mm-0.06mm.

[0028] In the above-mentioned third specific embodiment, the base material of the substrate layer 1 is polystyrene (PS), which has a relatively low water absorption rate so that the diffusion plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Single layer thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com