Manufacturing technology of individual hydraulic prop piston

A single hydraulic prop and production process technology, which is applied to forging presses, forging presses, manufacturing tools, etc., can solve the problems of piston blank size, poor weight control, high labor intensity of operators, and low quality of piston products. The effect of saving raw materials, low production efficiency and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

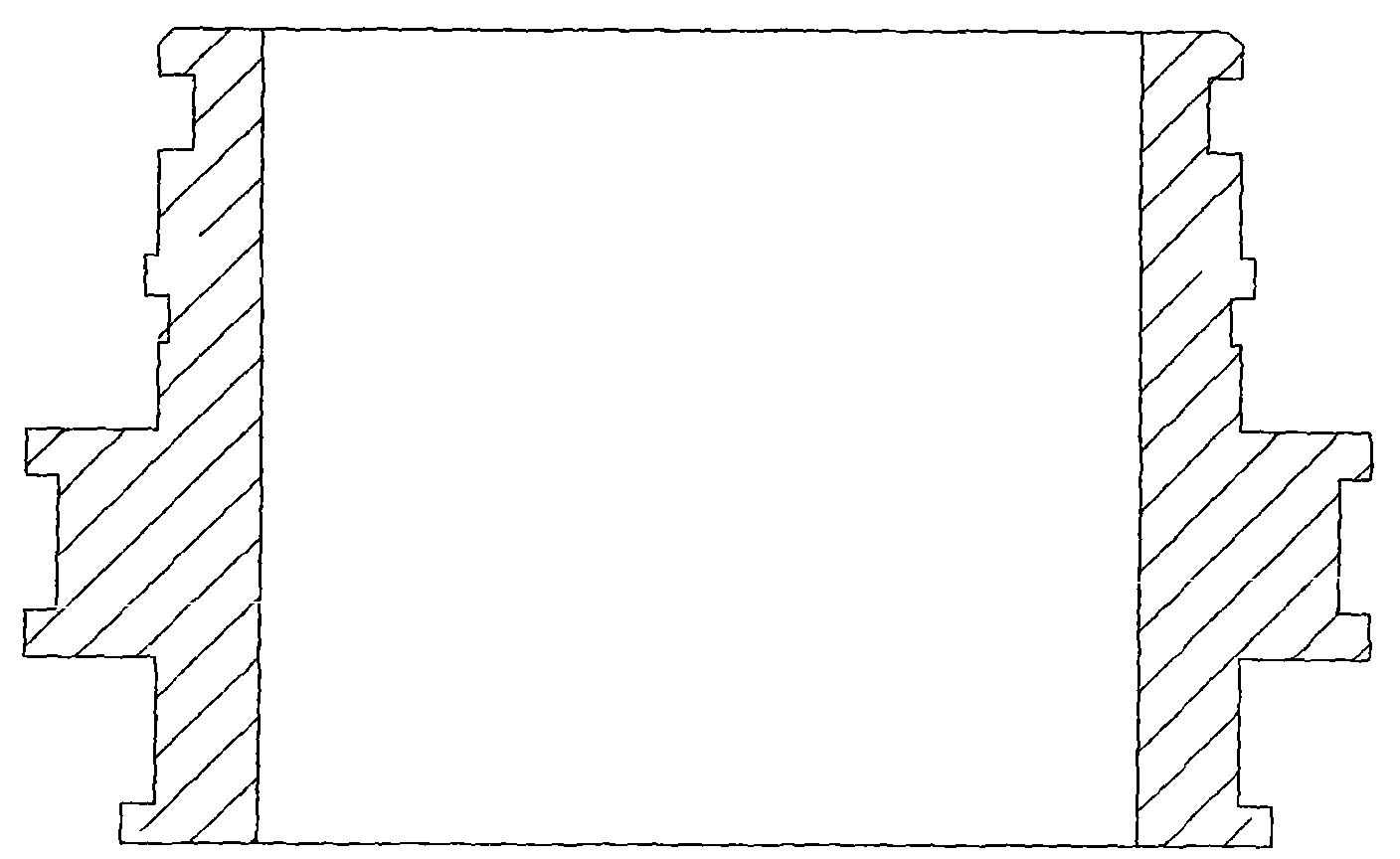

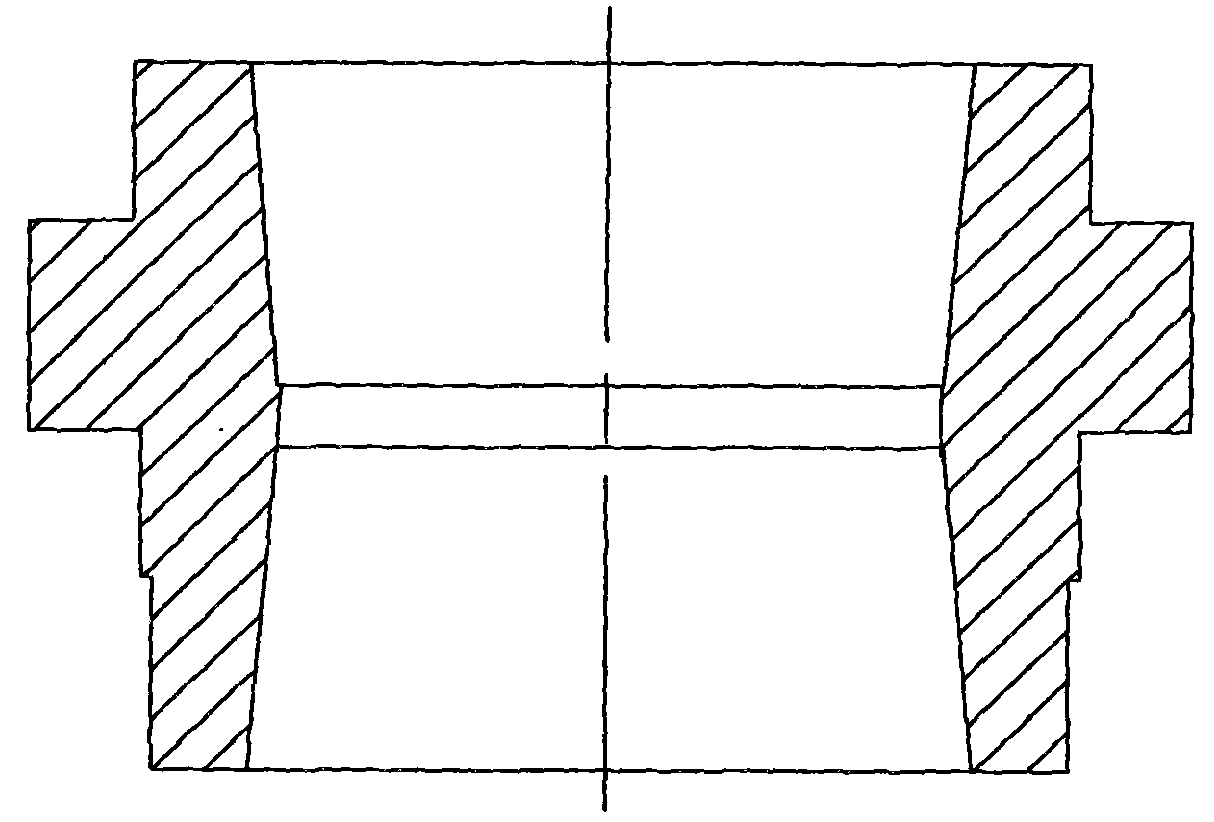

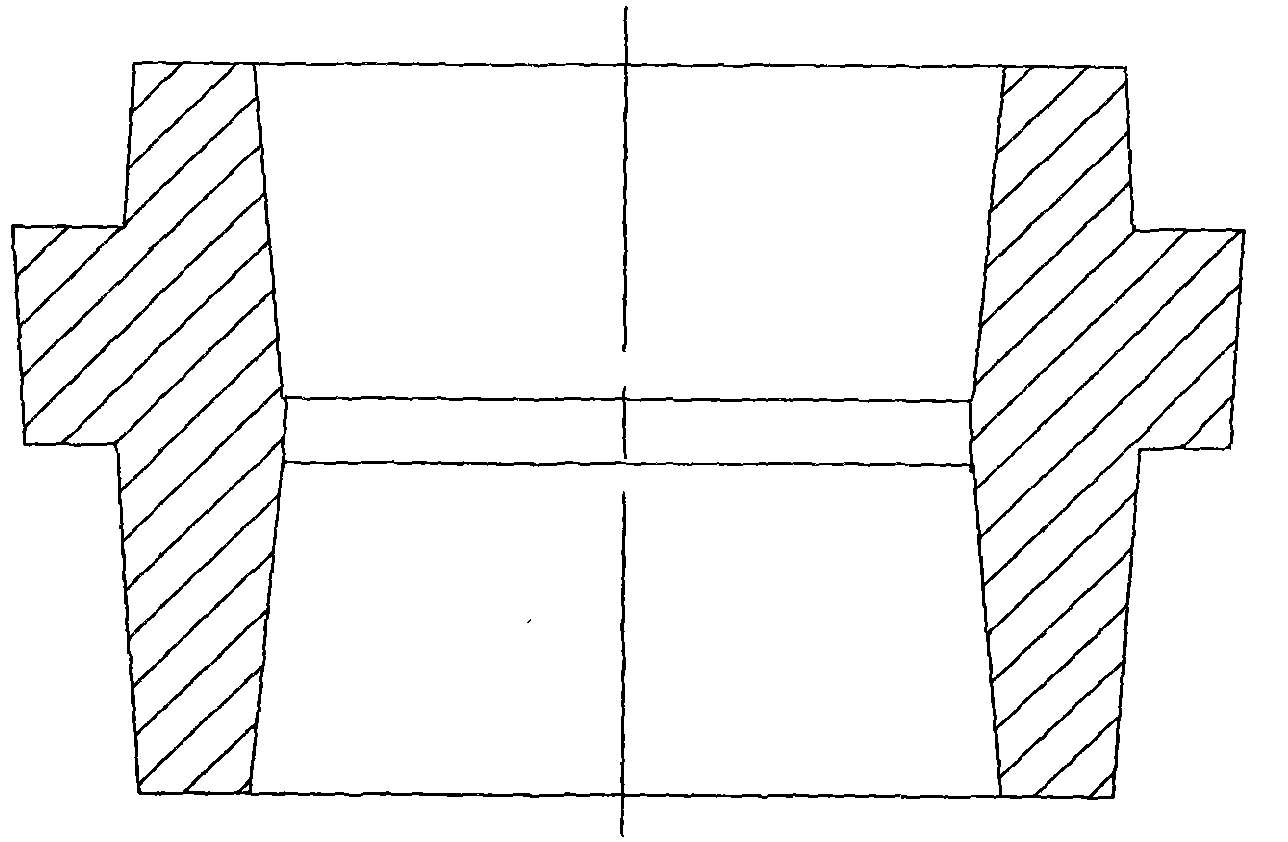

[0027] Embodiment 1: Purchase a round steel with a diameter of 55mm, blank 1.55Kg, heat the round steel after blanking to 900°C with a 300KW intermediate frequency induction heating furnace, and then press the heated round steel on a 100-ton punch to form a diameter The round billet is 82±1mm, put the round billet into the mold of a 630-ton friction press for split-type closed forging, and the automatic ejector device of the friction press ejects the piston forging and the inner mold (the shape of the forged piston forging is as follows figure 2 As shown), the operator clamps both ends of the piston forging with pliers, and after cooling in tap water for 3 seconds, a single piston forging is placed in the air to cool to room temperature; then the piston forging is roughed and finished by a lathe once.

[0028] In this embodiment, the production cost of each DW-type piston is 2.2 yuan lower than that of the current process.

Embodiment 2

[0029] Embodiment 2: Purchase a round steel with a diameter of 55mm, blank 1.58Kg, heat the round steel after blanking to 1000°C with a 300KW intermediate frequency induction heating furnace, and then press the heated round steel on a 160-ton punch to form a diameter The round billet is 82±1mm, put the round billet into the mold of a 630-ton friction press for split-type closed forging, and the automatic ejector device of the friction press ejects the piston forging and the inner mold (the shape of the forged piston forging is as follows figure 2 As shown), the operator clamps both ends of the piston forging with pliers, and after cooling in tap water for 5 seconds, a single piston forging is placed in the air to cool to room temperature; then the piston forging is roughed and finished by a lathe once.

[0030] In this embodiment, the production cost of each DW-type piston is 3 yuan lower than that of the current process.

Embodiment 3

[0031] Embodiment 3: Purchase a round steel with a diameter of 55mm, blank 1.68Kg, heat the round steel after blanking to 900°C with a 300KW intermediate frequency induction heating furnace, and then press the heated round steel on a 160-ton punch to form a diameter The round billet is 82±1mm, put the round billet into the mold of a 630-ton hot die forging press for closed forging, and the automatic ejector device of the friction press ejects the piston forging and the inner mold (the shape of the forged piston forging is as follows figure 2 shown), the operator clamps both ends of the piston forging with pliers, and after cooling in tap water for 6 seconds, a single piston forging is placed in the air to cool to room temperature; then the piston forging is roughed and finished by a lathe once.

[0032] In this embodiment, the production cost of each DW-type piston is 3.0 yuan lower than that of the current process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com