Refuse leachate ammonia nitrogen handling arrangement

A landfill leachate and treatment device technology, applied in the direction of sustainable biological treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of reduced nitrification reaction rate, reduced nitrification activity, increased operating costs and management The difficulty and other issues, to achieve the effect of low manufacturing and operating costs, high removal rate, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

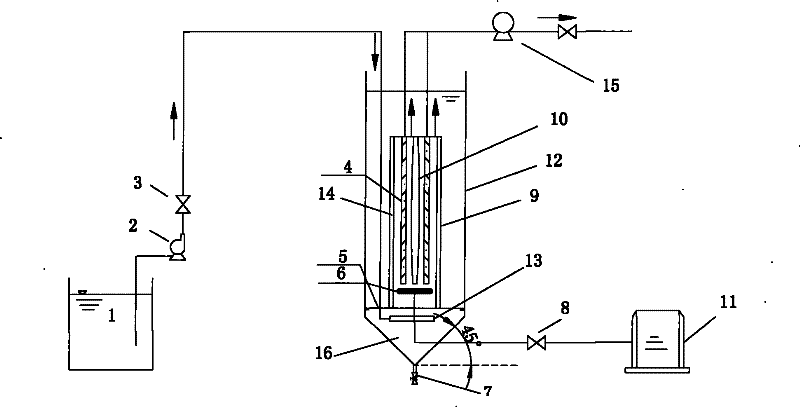

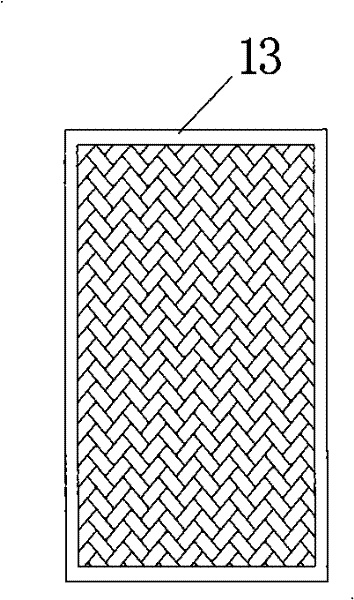

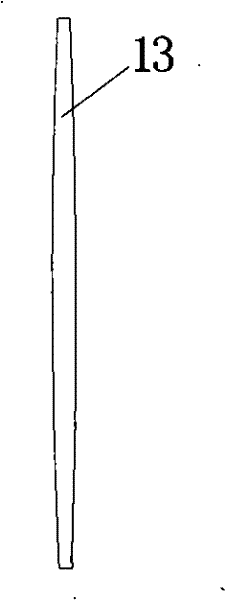

[0028] Such as Figure 1-8 As shown, the present invention is provided with a reaction tank 12, a supporting plate 5, a composite membrane-bag assembly 9, a water distribution pipe 13, an air distribution pipe 6, a mud discharge chamber 16 and a mud discharge valve 7. The supporting plate 5 is located at the bottom of the reaction tank 12, the composite film-cloth bag assembly 9 is located on the supporting plate 5, the composite film-cloth bag assembly 9 is provided with a non-woven bag 10 and a deflector 14, the non-woven bag 10 The inside is filled with oyster shell particles, the two sides of the non-woven bag 10 are respectively provided with a flat diaphragm 4 , and the deflector 14 is placed outside the diaphragm 4 . The air distribution pipe 6 is arranged above the support plate 5 and below the diaphragm, the air distribution pipe 6 is connected to the aerator 11, and the aerator 11 sends air into the air distribution pipe 6. The water distribution pipe 13 is located ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com