Asphalt material with high-strength structure and preparation method thereof

A structural asphalt and high-strength technology, which is applied in the field of high-strength structural asphalt material and its preparation, can solve the problems of affecting the modulus performance of the mixture, poor cohesiveness, melting and dispersion of additives, etc., and achieve low production cost and high melting index. The effect of improving and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

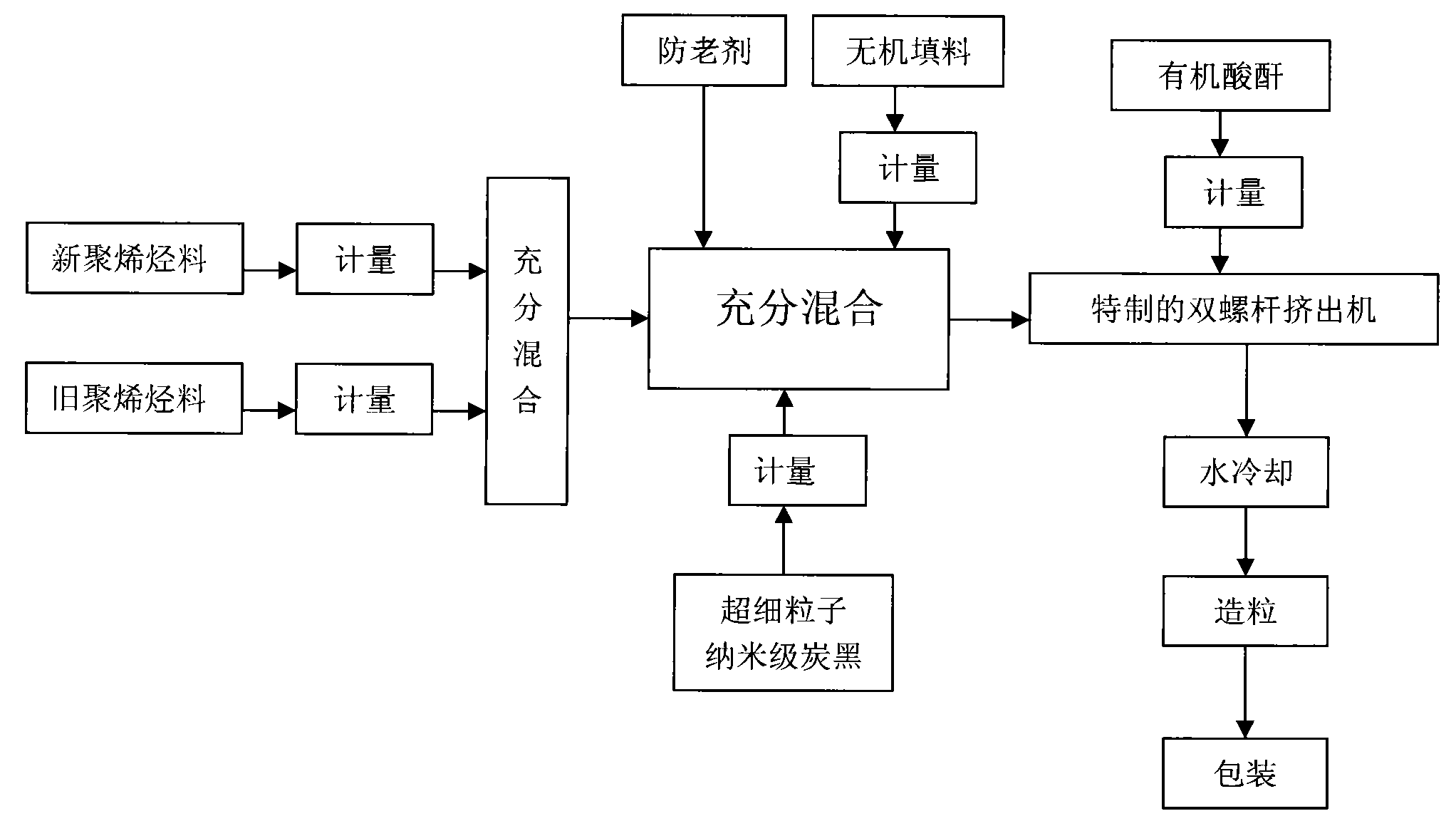

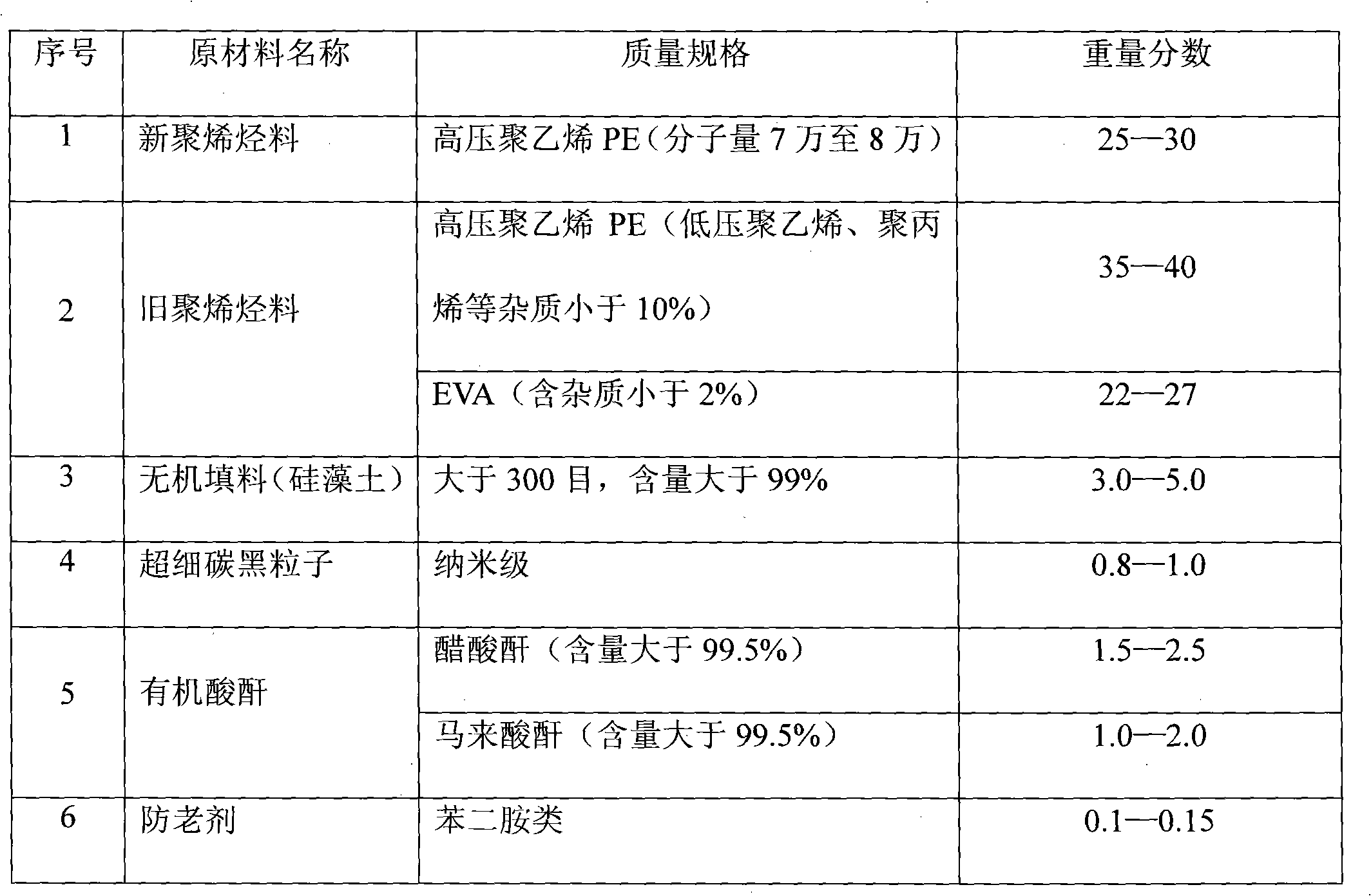

[0025] As shown in the figure, a high-strength structural asphalt material, including new polyolefin material, old polyolefin material, inorganic filler, ultrafine carbon black particles, organic acid anhydride, anti-aging agent, is characterized in that its weight ratio is: 25-30 parts of new polyolefin material, 57-67 parts of old polyolefin material, 3-5 parts of inorganic filler, 0.8-1 part of ultra-fine carbon black particles, 2-4.5 parts of organic acid anhydride, 0.1-0.15 parts of anti-aging agent, etc. The production and preparation process is as follows:

[0026] A. Measure 25-30 parts by weight of new polyolefin material and 57-67 parts by weight of old polyolefin material after type selection and evaluation, and put them into the mixer respectively, start the mixer and mix for 30-40 minutes to make them fully mixed;

[0027] B. Put the measured 3-5 parts by weight of inorganic filler, 0.8-1 parts by weight of ultrafine carbon black particles and 0.1-0.15 parts by we...

Embodiment 2

[0032] As shown in the figure, a high-strength structural asphalt material, including new polyolefin material, old polyolefin material, inorganic filler, ultrafine carbon black particles, organic acid anhydride, anti-aging agent, is characterized in that its weight ratio is: 25-30 parts of new polyolefin material, 57-67 parts of old polyolefin material, 3-5 parts of inorganic filler, 0.8-1 part of ultra-fine carbon black particles, 2-4.5 parts of organic acid anhydride, 0.1-0.15 parts of anti-aging agent, etc. The production and preparation process is as follows:

[0033] A. Measure 28 parts by weight of new polyolefin material and 62 parts by weight of old polyolefin material after type selection and evaluation, and put them into the mixer respectively, and start the mixer to mix for 30-40 minutes to make them fully mixed;

[0034] B, 3.5 parts by weight of inorganic fillers, 0.86 parts by weight of superfine carbon black particles and 0.11 parts by weight of anti-aging agent...

Embodiment 3

[0039] The inorganic filler described in embodiment 1 and embodiment 2 is diatomite, and described organic acid anhydride is acetic anhydride and maleic anhydride mixture, and described old polyolefin material is high-pressure polyethylene ion material PE and EVA material mixture, The ultrafine carbon black particles are ultrafine nanoscale ultrafine carbon black particles. The weight portion of the acetic anhydride is 1.5-2.5, the weight portion of the maleic anhydride is 1-2, the weight portion of the high-pressure polyethylene ion material PE is 35-40, and the weight portion of the EVA material is 22 -27.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com