Sepiolite fiber modified vitrification bead thermal insulation mortar

A technology of sepiolite fiber and vitrified microbeads, which is applied in the field of thermal insulation mortar and its preparation, and vitrified microbeads, which can solve the problems of unstable construction performance, hollowing and cracking, and low cost, and achieve easy quality control and supply The effect of long time and excellent construction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: A kind of sepiolite fiber modified vitrified bead insulation mortar, its components and proportioning (mass percentage) are:

[0031] Cement: 40.1%, fly ash: 10.9%, slaked lime: 3%, vitrified microspheres: 43.5%, sepiolite fiber: 0.6%, redispersible latex powder: 1.5%, methyl cellulose ether: 0.29% , starch ether: 0.07%, air-entraining agent: 0.01%.

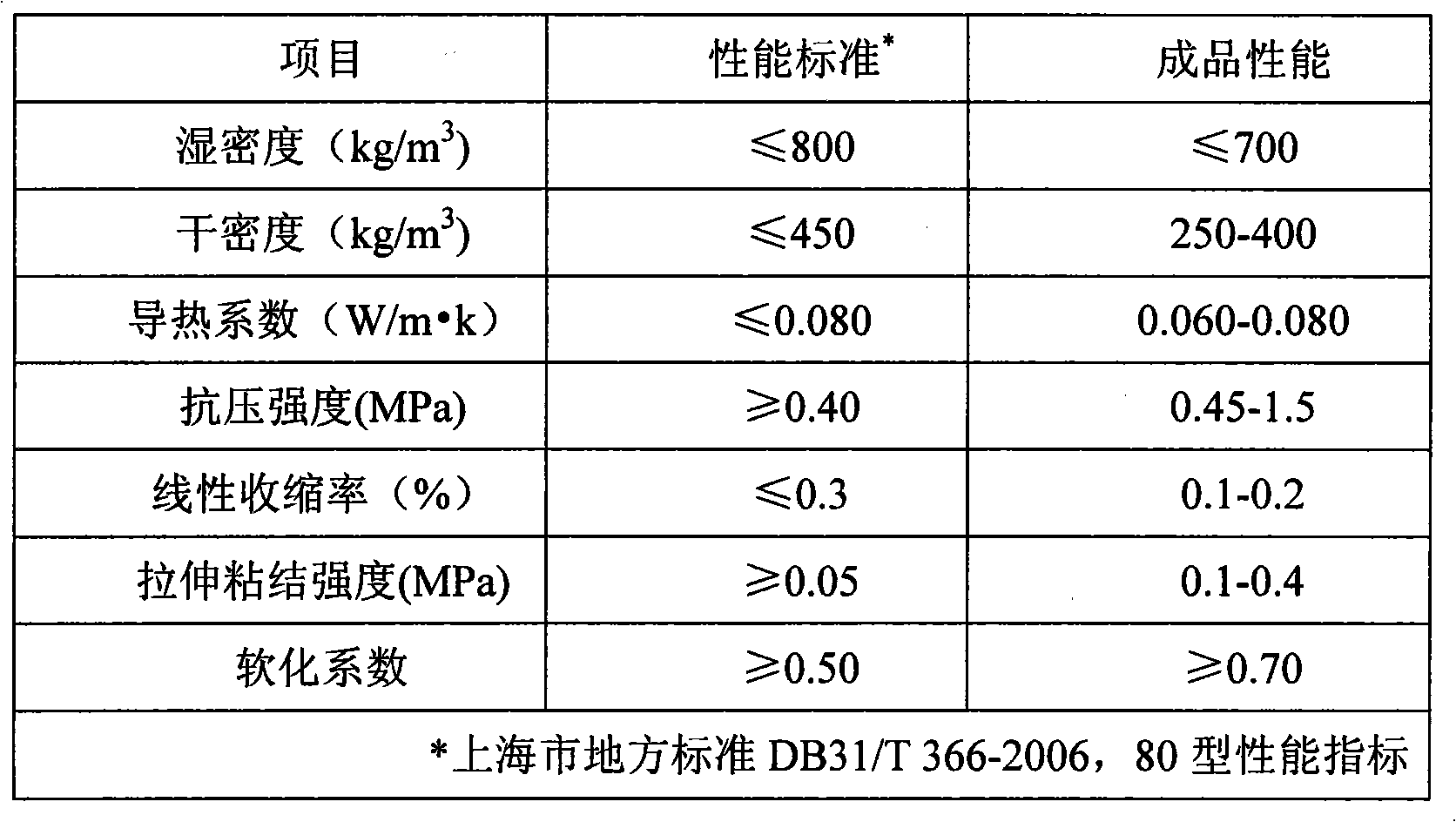

[0032] Table 2 Example-1 Performance Index of Sepiolite Fiber Modified Vitrified Bead Thermal Insulation Mortar

[0033] project

Embodiment 2

[0034] Embodiment 2: A kind of sepiolite fiber modified vitrified bead insulation mortar, its components and proportioning (mass percentage) are:

[0035] Cement: 41.8%, fly ash: 7.5%, slaked lime: 2.5%, vitrified microspheres: 46.3%, sepiolite fiber: 0.5%, redispersible latex powder: 1.1%, methyl cellulose ether: 0.21% , Starch ether: 0.05%, air-entraining agent: 0.01%.

[0036] Table 3 Example-2 Performance indicators of sepiolite fiber modified vitrified microbead thermal insulation mortar

[0037] project

Embodiment 3

[0038] Embodiment 3: A kind of sepiolite fiber modified vitrified bead insulation mortar, its components and proportioning (mass percentage) are:

[0039] Cement: 53.1%, fly ash: 5%, slaked lime: 3%, vitrified microspheres: 36.9%, sepiolite fiber: 0.5%, redispersible latex powder: 1.2%, methyl cellulose ether: 0.25% , starch ether: 0.07%, air-entraining agent: 0.01%.

[0040] Table 4 Example-3 Performance Index of Sepiolite Fiber Modified Vitrified Bead Thermal Insulation Mortar

[0041] project

[0042] It can be seen from the above examples that sepiolite fiber-modified vitrified microbead thermal insulation mortar can prepare thermal insulation mortar with different thermal conductivity. All indicators meet the engineering requirements, and can be popularized and used as high-performance wall insulation materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Dry apparent density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com