Ce-contained rare-earth polishing powder and preparation method thereof

A technology of rare earth polishing powder and polishing powder, which is applied in the direction of polishing compositions containing abrasives, etc., to achieve the effect of simple preparation process, easy process, and high polishing flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

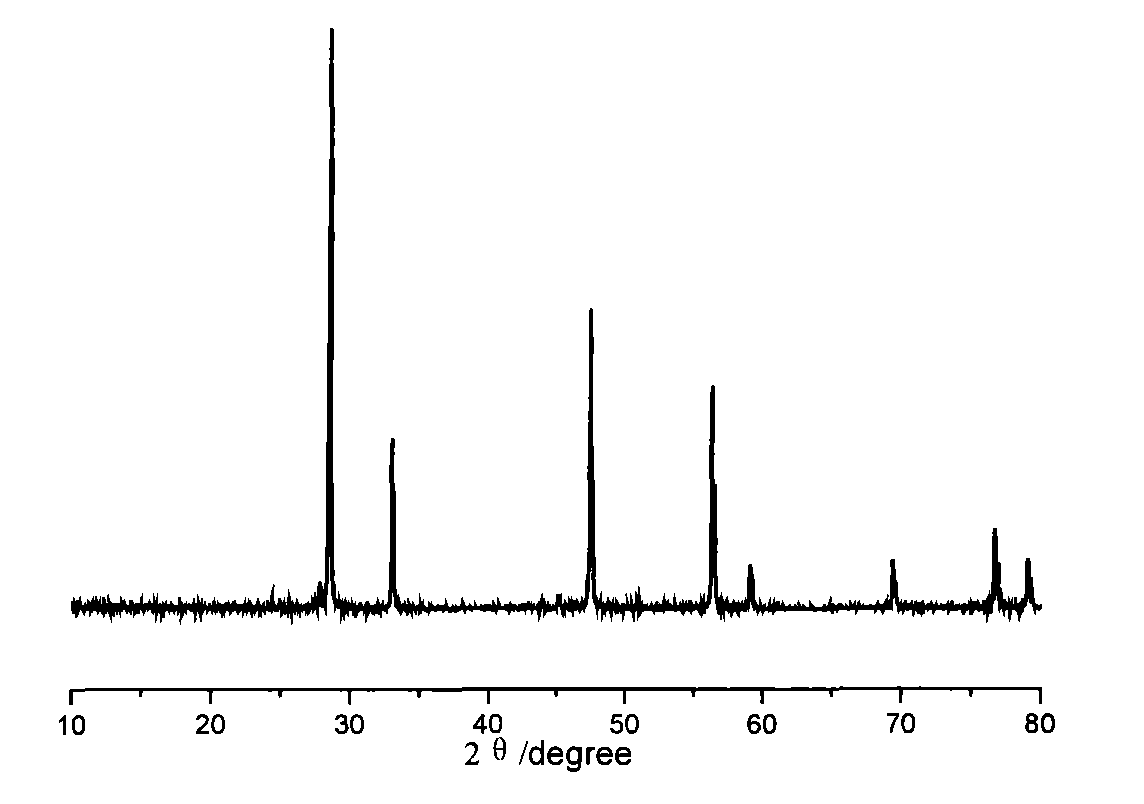

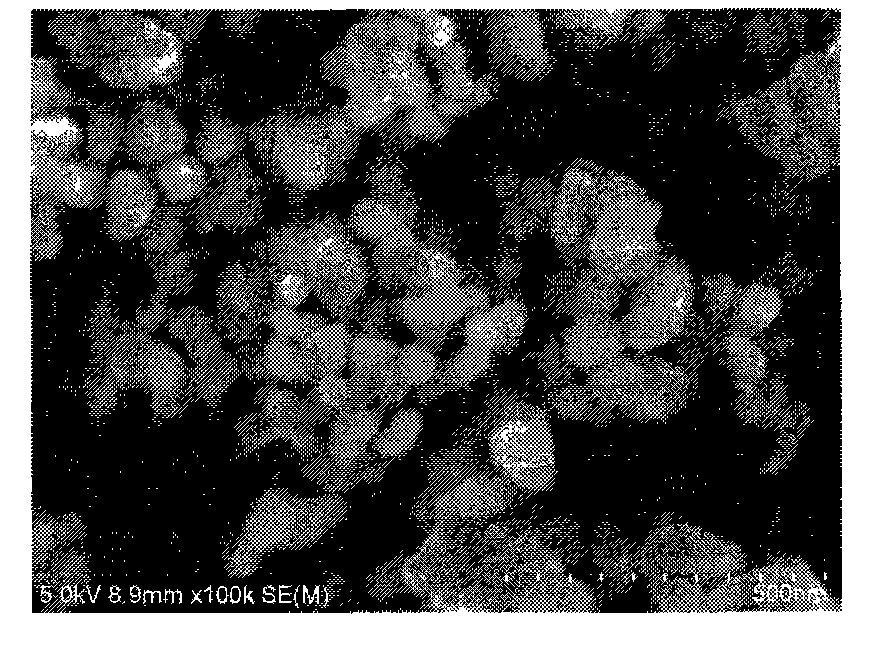

[0020] The polishing powder precursor cerium carbonate (wherein the molar ratio of cerium and total rare earth is 99.5%) is put into 700 ℃ of high-temperature furnaces and roasted for 2 hours, feeds N in the roasting furnace 2 , the maximum partial pressure of oxygen in the control atmosphere is 100Pa, and the final rare earth polishing powder product containing trivalent cerium is obtained after ball milling and sieving. The median particle size is 0.07um, and the polishing powder Ce is measured by X-ray photoelectron spectroscopy (XPS). 3+ / ΣCe = 18.8%.

[0021] The trivalent cerium-containing polishing powder and the comparative sample were made into a 5% slurry, and the liquid crystal glass was polished under the same conditions. The cutting force of the trivalent cerium-containing polishing powder product was 0.010mm / h, and the visual scratch was 0 / m 2 .

Embodiment 2

[0023] The polishing powder precursor cerium oxalate (wherein the molar ratio of cerium and total rare earth is 99.5%) is put into 650 ℃ of high-temperature furnaces and roasted for 4 hours, feeds N in the roasting furnace 2 , the maximum partial pressure of oxygen in the control atmosphere is 300Pa, after ball milling and sieving, the median particle size of the final rare earth polishing powder product containing trivalent cerium is 0.36um, and the polishing powder Ce is determined by XPS 3+ / Ce = 15.6%.

[0024] The polishing powder and the comparison sample were made into 10% slurry, and the laser glass was polished under the same conditions. The cutting force of the polishing powder product was 0.014mm / h, and the visual scratch was 1 / m 2 .

Embodiment 3

[0026] The mixture of polishing powder precursor cerium oxalate and cerium carbonate (wherein the mol ratio of cerium and total rare earth is 99.9%) is put into the high-temperature furnace of 850 ℃ and roasted for 6 hours, and ammonium fluoride (accounting for rare earth polishing powder) is added in the roasting furnace 4% of content), after ball milling and sieving, finally obtain the rare earth polishing powder product containing trivalent cerium, the median particle diameter is 0.98um, XPS measures polishing powder Ce 3+ / ∑Ce=5.6%.

[0027] Make 10% slurry of polishing powder and comparative sample, and polish zf glass under the same conditions. The cutting force of polishing powder product is 0.020mm / h, and the visual scratch is 1 / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com