Thermal and strengthened insulating glass spacer bar

A spacer and glass technology, which is applied in windows/doors, building components, buildings, etc., can solve problems such as poor thermal insulation performance, increased energy consumption of heating and air conditioning, and achieve low thermal conductivity, low cost, and high cost performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

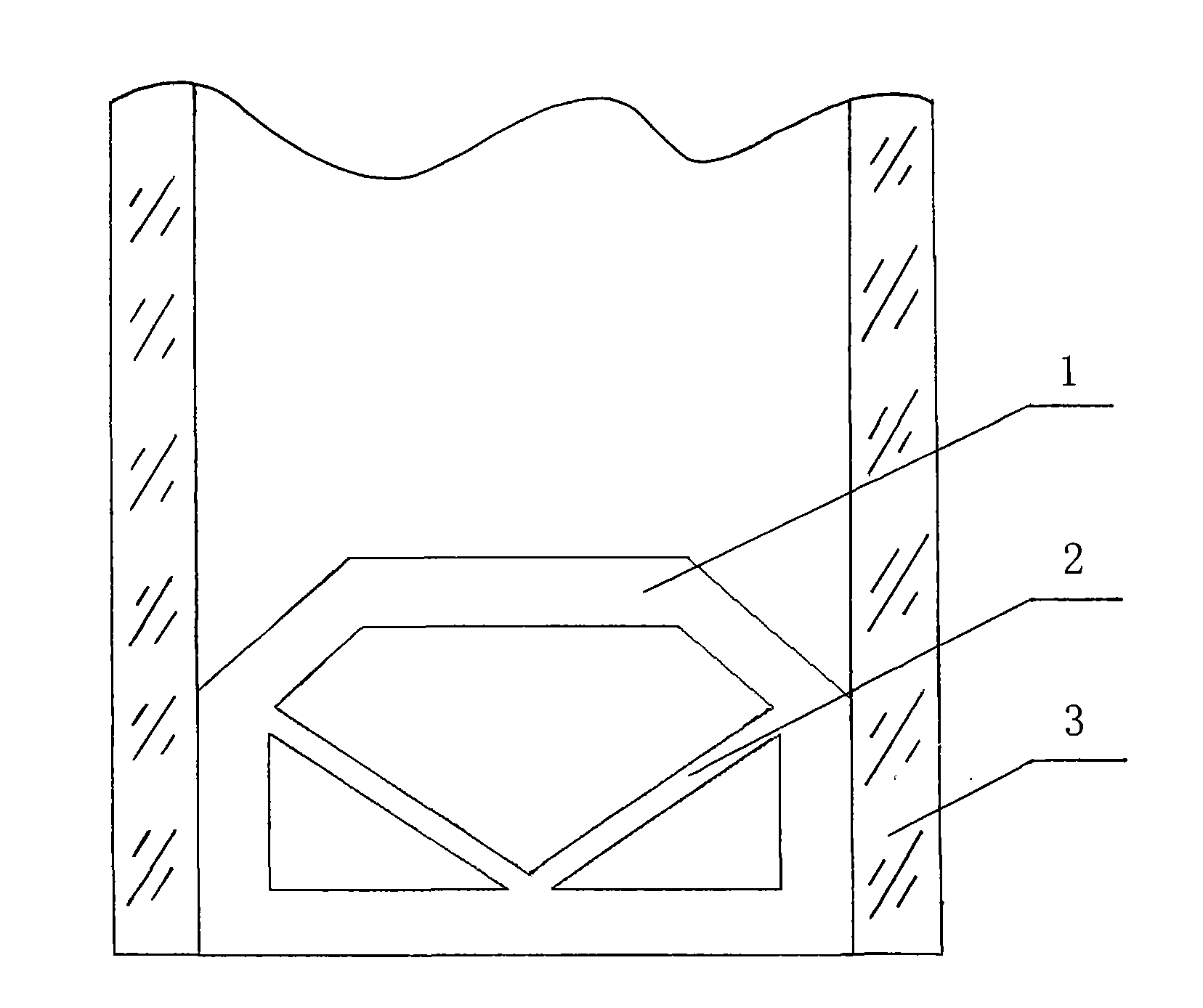

Image

Examples

Embodiment Construction

[0012] The present invention is described in detail below with reference to accompanying drawing:

[0013] The invention adopts a coupled control precision extrusion process. It divides the content of precision extrusion into two systems: flow system and size system, and adopts dual system coupling to meet the requirements of stability and precision. The flow system achieves the stability of the extrusion flow on the basis of improving the barrel screw temperature control, screw speed control and traction speed control level, rationally designing the screw structure of the extruder, and optimizing the flow rate of the extruder head. The size system adopts The controllable multi-point primary cold sizing and multi-point secondary thermal sizing coupling approach size can obtain high-precision size of extruded products. In the dual system coupling method of the flow system and the size system, the temperature of the barrel screw, the screw speed and the traction speed are incre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com