Uses of a marine yeast and corresponding microorganism fuel cell and method for preparing the same

A fuel cell and marine yeast technology, applied in biochemical fuel cells, fuel cell parts, battery electrodes, etc., can solve problems such as no marine yeast involved, and achieve the effects of long operation cycle, rapid cell reproduction, and low consumption of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

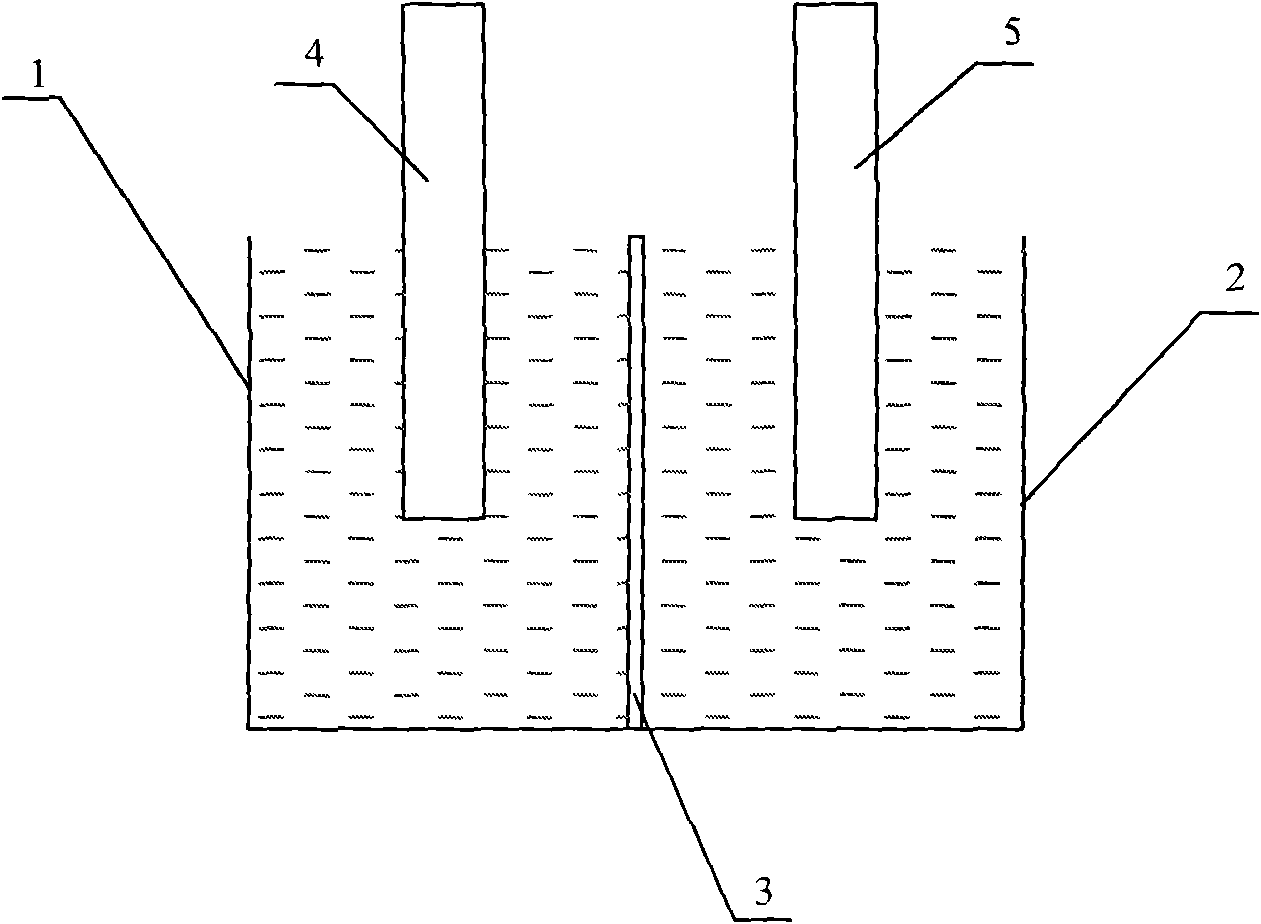

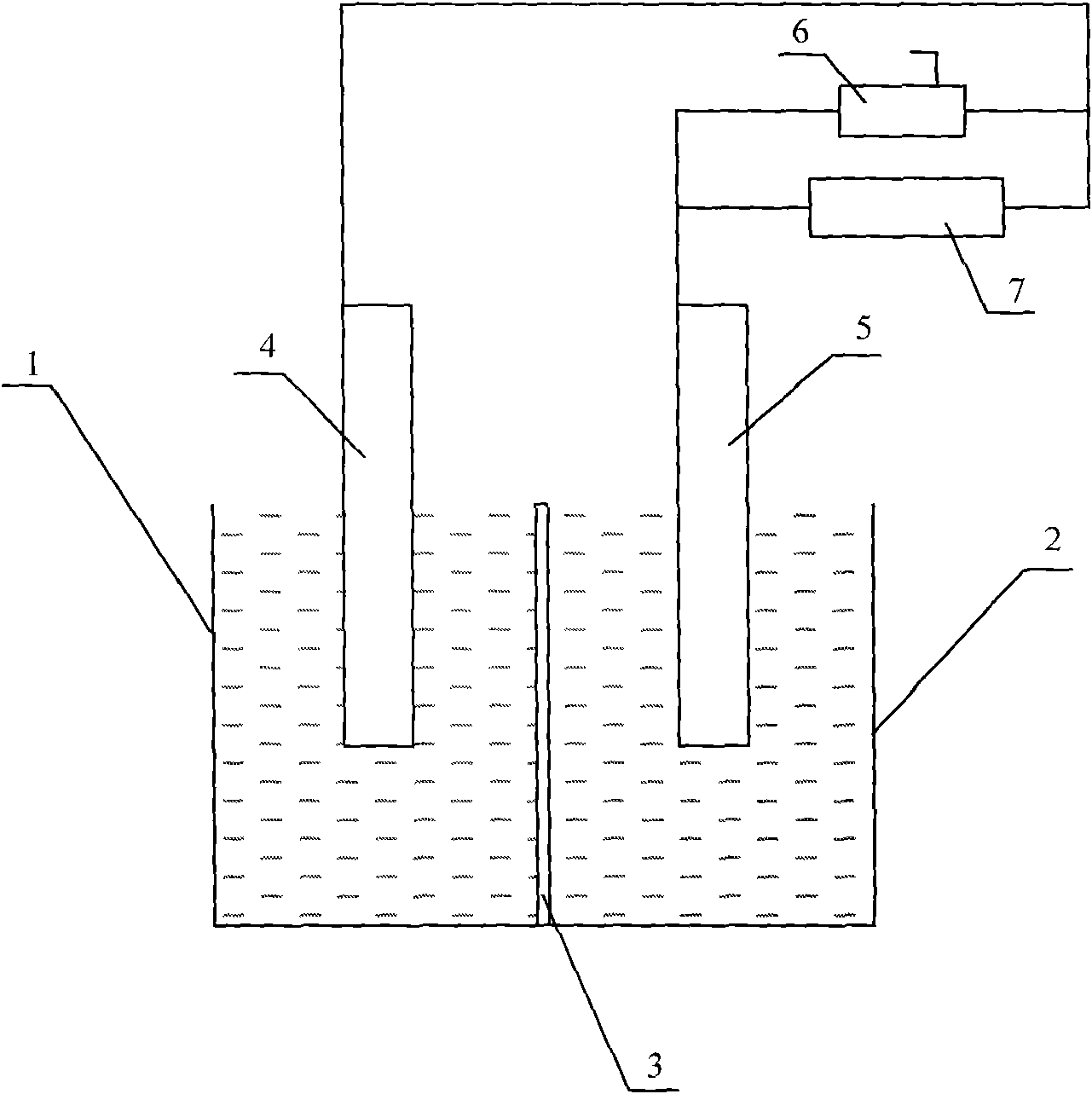

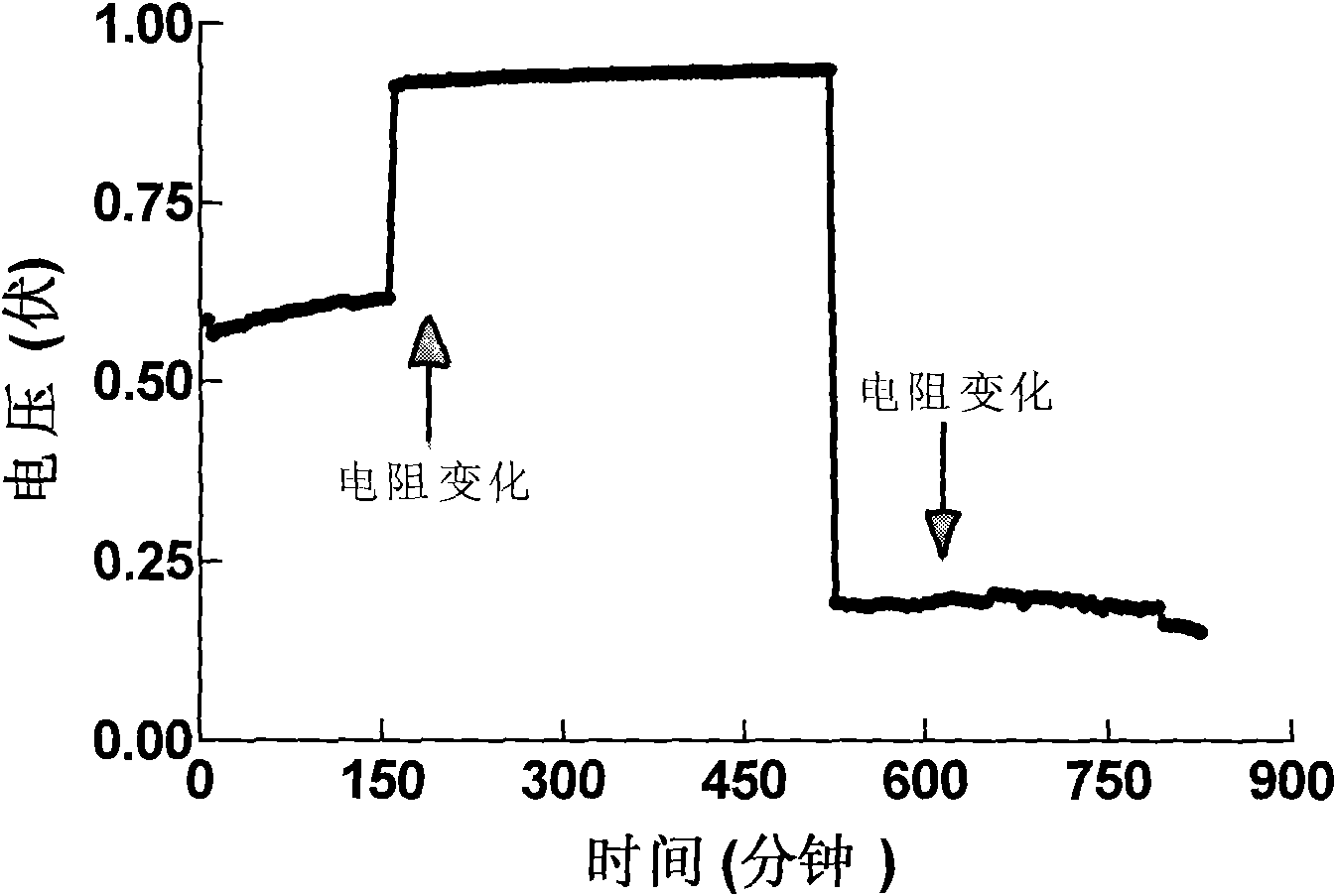

[0047] Embodiment 1, figure 1 A microbial fuel cell is given, comprising an open anode chamber 2 and an open cathode chamber 1, the capacity of the anode chamber 2=the capacity of the cathode chamber 1=216ml. Both the anode chamber 2 and the cathode chamber 1 are made of plexiglass. The anode chamber 2 and the cathode chamber 1 are separated by the proton exchange membrane 3. The proton exchange membrane 3 is made by the following method: on a permeable microporous ceramic membrane Both sides are coated with a layer of Nafion-117 solution, obtained after drying. The permeable microporous ceramic membrane can be selected from the Nafion series membrane produced by DuPont. An organic fuel liquid containing bacterial liquid is arranged in the anode chamber 2, and the bacterial liquid is the bacterial liquid obtained after fermentation of marine yeast with a preservation number of IMI 394084; a potassium ferricyanide solution is provided in the cathode chamber 1; An anode electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com