Formable high strength cold-rolled steel sheet with excellent weather resistance and method manufacturing the same

A technology of cold-rolled steel sheet and weather resistance, applied in the field of formable high-strength cold-rolled steel sheet and its manufacture, can solve problems such as low tensile strength and achieve the effect of excellent workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

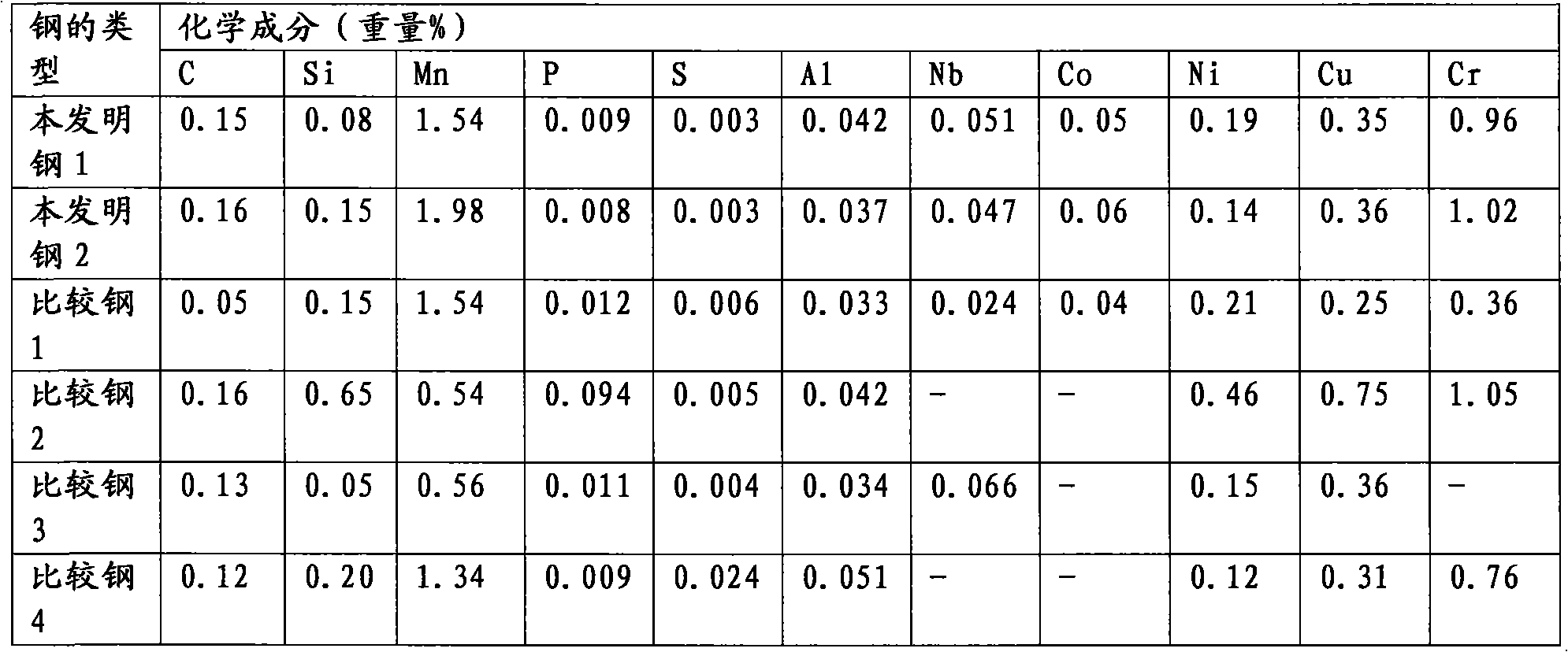

[0056] The normalized corrosion resistance coefficient (CI) and weather resistance of steels having the compositions shown in Table 1 below were measured. The results are listed in Table 2 below.

[0057] As a weather resistance test, a salt spray test (SST) of steel was carried out in 5% salt water (NaCl solution) at 30° C. for 480 hours. The results are listed in Table 2 below.

[0058] The corrosion resistance coefficient is a coefficient obtained by evaluating the weather resistance of steel according to the ASTM G101 standard. It is known that the weather resistance of steel is optimized with increasing corrosion resistance coefficient. Here, the corrosion resistance coefficient is mainly calculated based on alloying elements and expressed by the following formula:

[0059] Corrosion Resistance Coefficient (CI)=26.01(%Cu)+3.88(%Ni)+1.2(%Cr)+1.49(%Si)+17.28(%P)-7.29(%Cu)(%Ni)-9.10(% Ni)(%P)-33.39(%Cu) 2

[0060] Table 1

[0061]

[0062] Table 2

[0063] ...

Embodiment approach 2

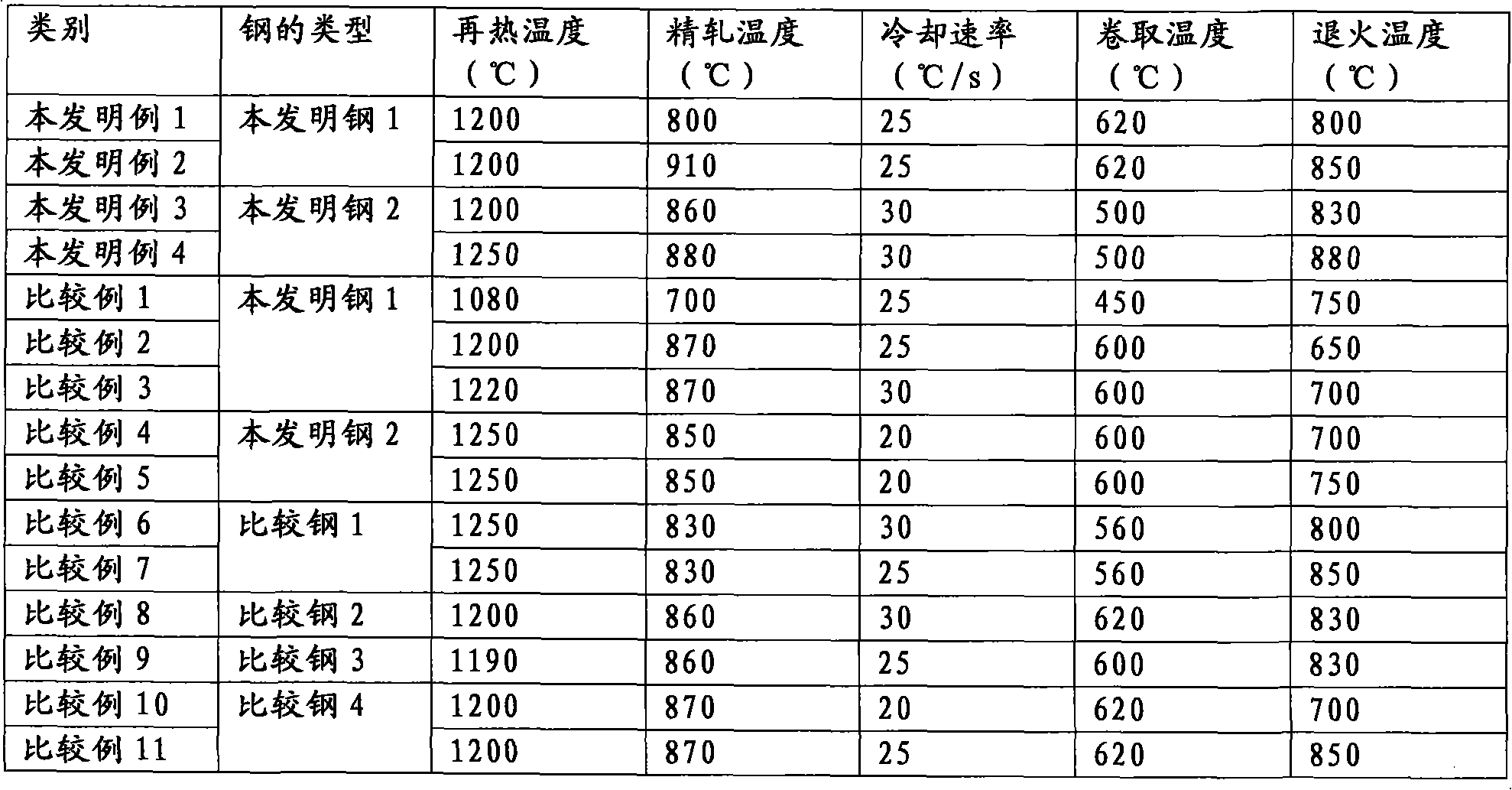

[0066] Each cold-rolled steel sheet was prepared from inventive steels 1 and 2 and comparative steels 1 to 4 shown in Table 1 of Embodiment 1 under the conditions shown in Table 3 below, and the mechanical properties and machining of the cold-rolled steel sheets were measured characteristic. The results are listed in Table 4 below.

[0067] table 3

[0068]

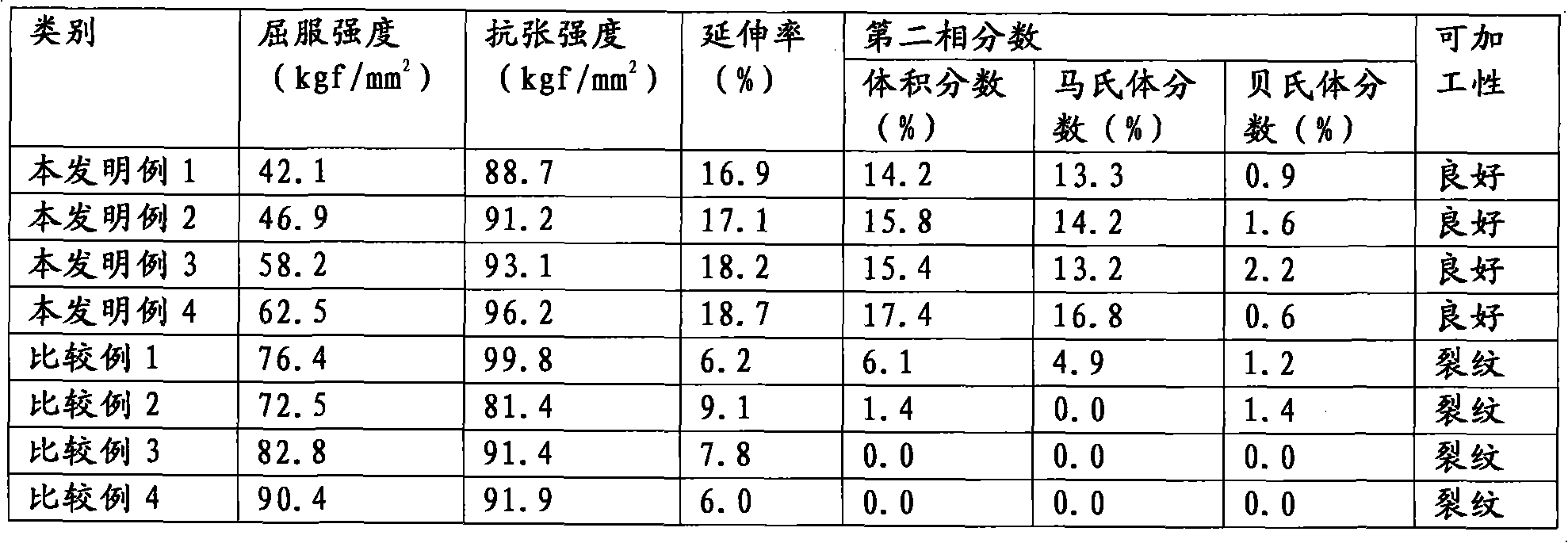

[0069] Table 4

[0070]

[0071]

[0072] As shown in Table 4, it can be seen that compositions 1 to 4 of the present invention—wherein the content ranges of the chemical components in the steel of the present invention and the manufacturing conditions of the steel of the present invention meet the requirements of the method of the present invention—have 80kgf / mm 2 or greater tensile strength, and have a volume fraction of the second phase including the martensite phase of 10% or greater after the annealing process. Therefore, cold-rolled steel sheets with weather resistance, high strength, and high workabilit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com