Micro-net component with continuous mobile line-shaped backwash and distributed with shock absorption and application method thereof

A backwash and micro-grid technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of difficult to guarantee water quality, difficult to improve water yield, and high equipment idle rate, so as to improve the flux of treated water and solve the problem of The effect of generating unevenness and increasing the micro mesh area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

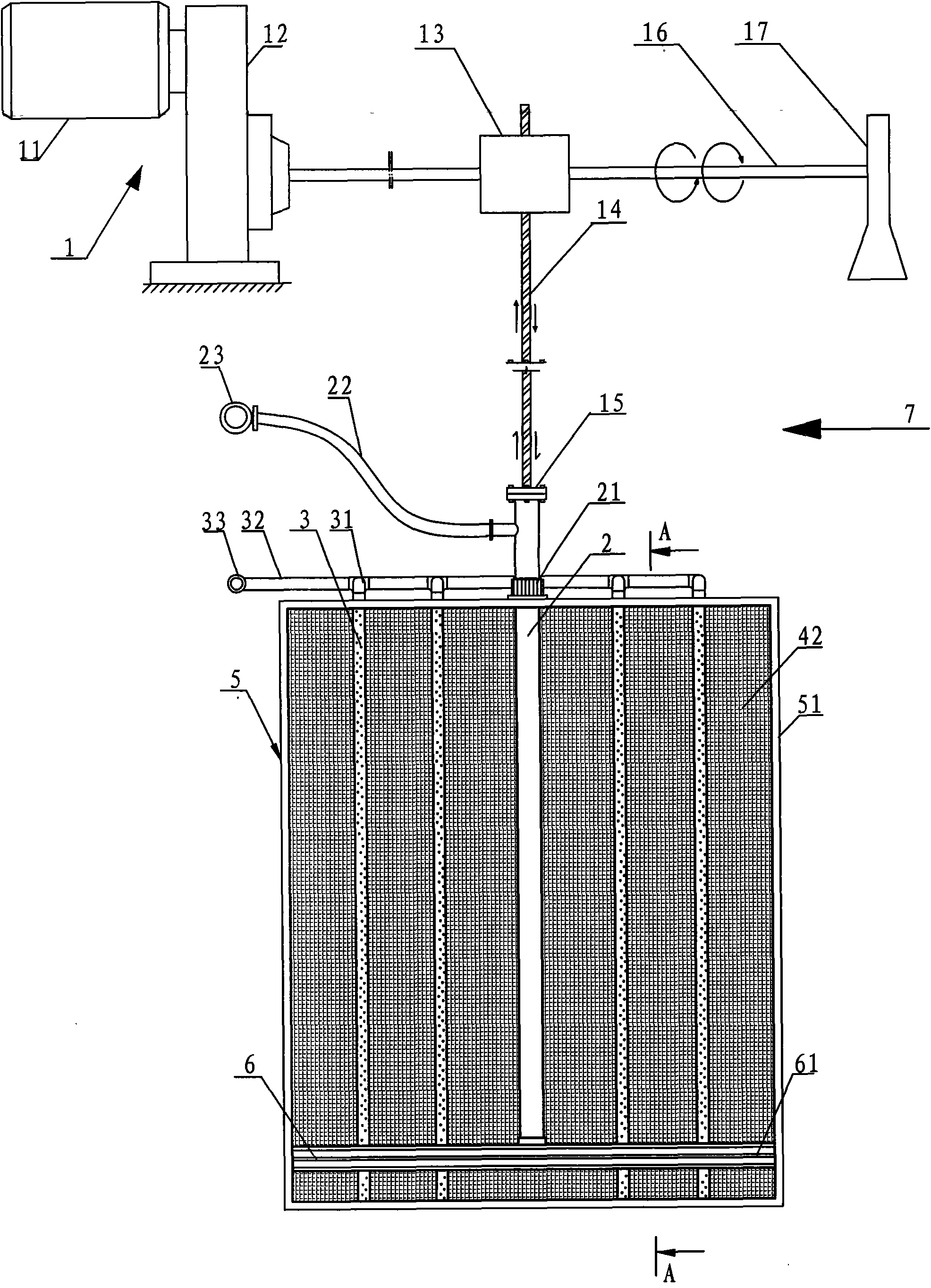

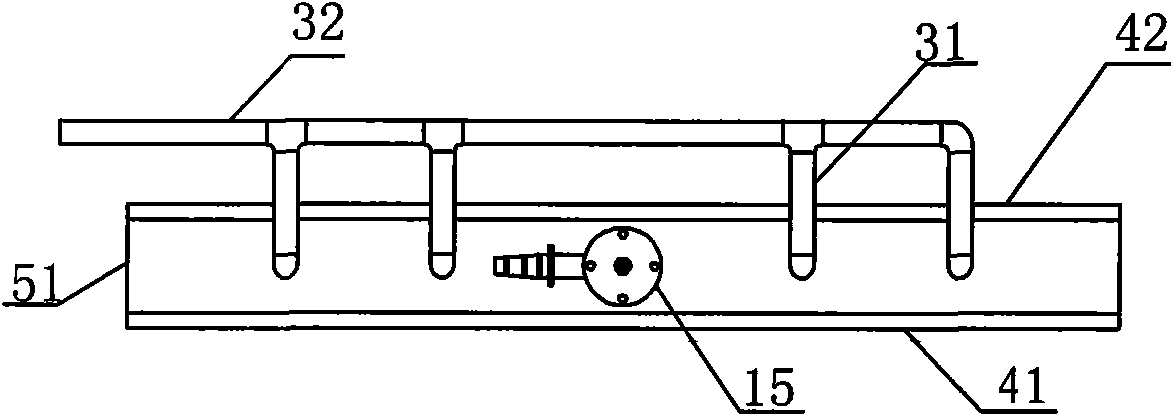

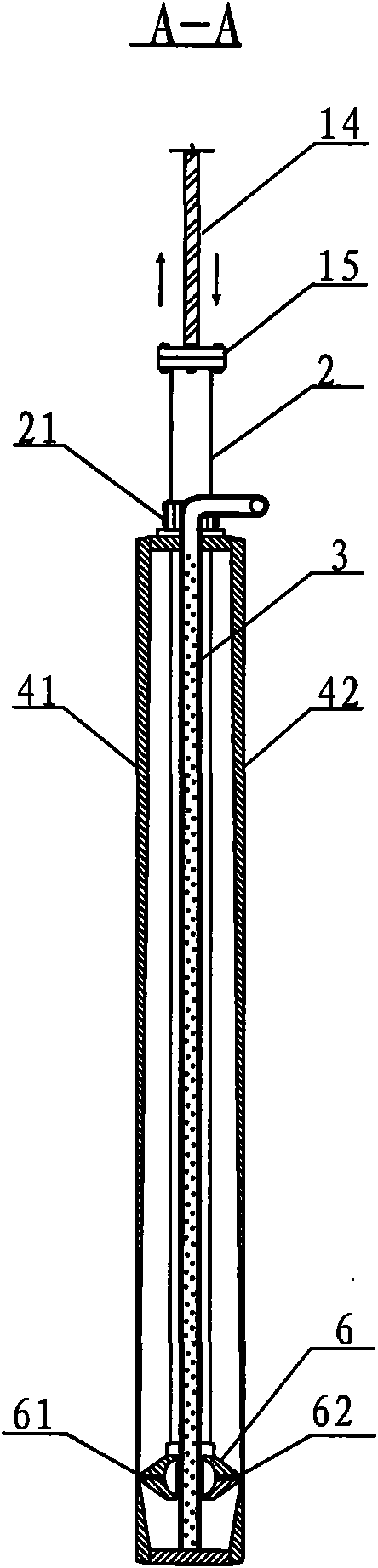

[0025] Figure 1-Figure 4 It shows a micro-grid assembly with continuous moving linear backwashing and distributed vibration reduction, including a square frame 51 surrounded by rigid impermeable upper, lower, left, and right panels and fixedly packaged on both ends of the frame. The hollow cuboid box 5 formed by the micro-grids 41, 42 is characterized in that the micro-grids 41, 42 are formed by stacking 2-3 layers of micro-nets with different apertures of 200 to 500 meshes; The mesh material can be stainless steel wire mesh, nylon, polyester and other chemical fiber mesh and non-woven fabrics, etc. In this example, three layers of micro-networks with 250 mesh, 360 mesh and 480 mesh from the outside to the inside are superimposed to form a micro-network body. The micro-net material adopts chemical fiber screen; the backwash support plate 6 is set in the above-mentioned box body 5, and one or more backwash water supply pipes 2 that drive the backwash support plate to move and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com