Device and method for measuring voltaic arc pressure distribution and current density distribution

A technology of current density and arc pressure, applied in current density measurement, arc welding equipment, manufacturing tools, etc., can solve the problems of no device, microscopic arc pressure, and few studies on current density distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

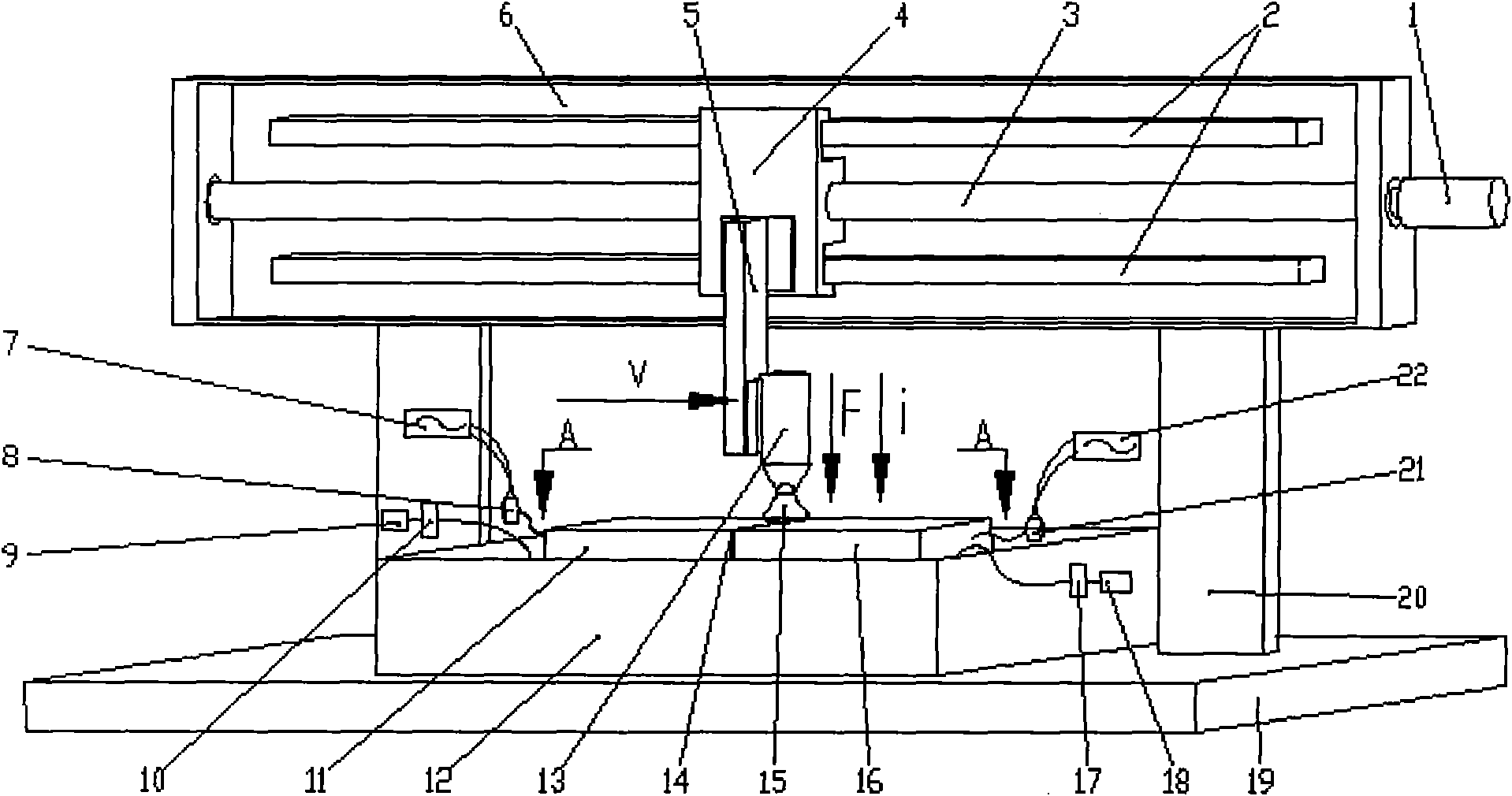

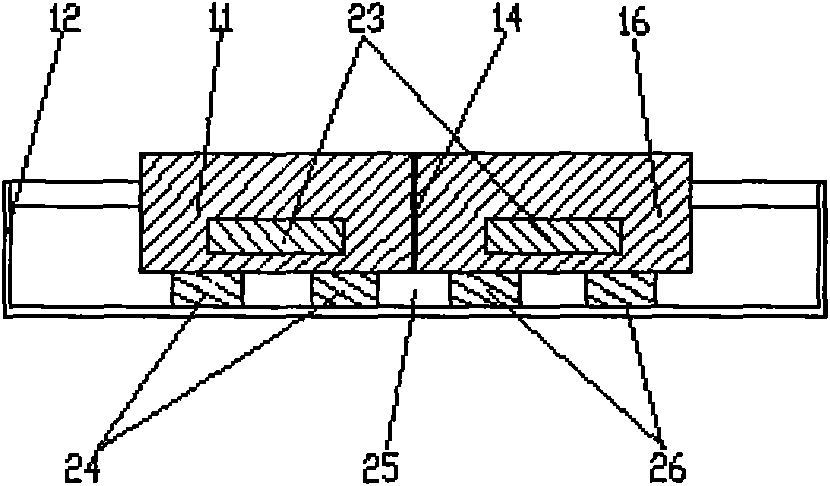

[0058] The concrete operation process of the present invention is described in detail below in conjunction with accompanying drawing:

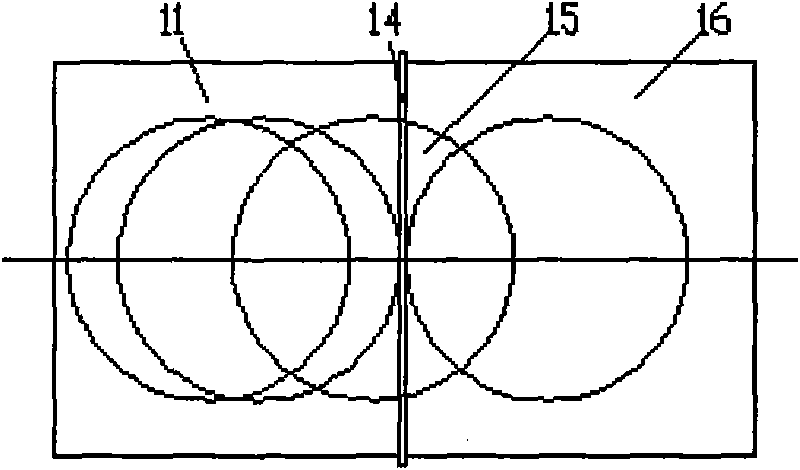

[0059] Such as figure 1 , figure 2 As shown, the device of the present invention includes: motor 1, guide rail 2, lead screw 3, welding torch position adjustment mechanism 5, left anode plate 11, right anode plate 16, cooling device (comprising container 12, cooling liquid 25), measuring arc force system (comprising left load cell 24, right load cell 26, lightweight block 23, left AD conversion module 10, right AD conversion module 17, left computer 9, right computer 18), measuring current system (comprising left current sensor 8, Right current sensor 21, left oscilloscope 7, right oscilloscope 22). The anode is composed of a left anode plate 11 and a right anode plate 16 located in the same plane, and the middle is completely separated by an insulating material 14 with a thickness of 50 microns to 150 microns. Two anode plates are all so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com