Liquid crystal orientation agent, liquid crystal display element, poly-amic acid, polyimide and compound

A technology of liquid crystal alignment agent and polyamic acid, which is applied in the direction of liquid crystal materials, chemical instruments and methods, instruments, etc., and can solve problems such as damage to liquid crystal alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

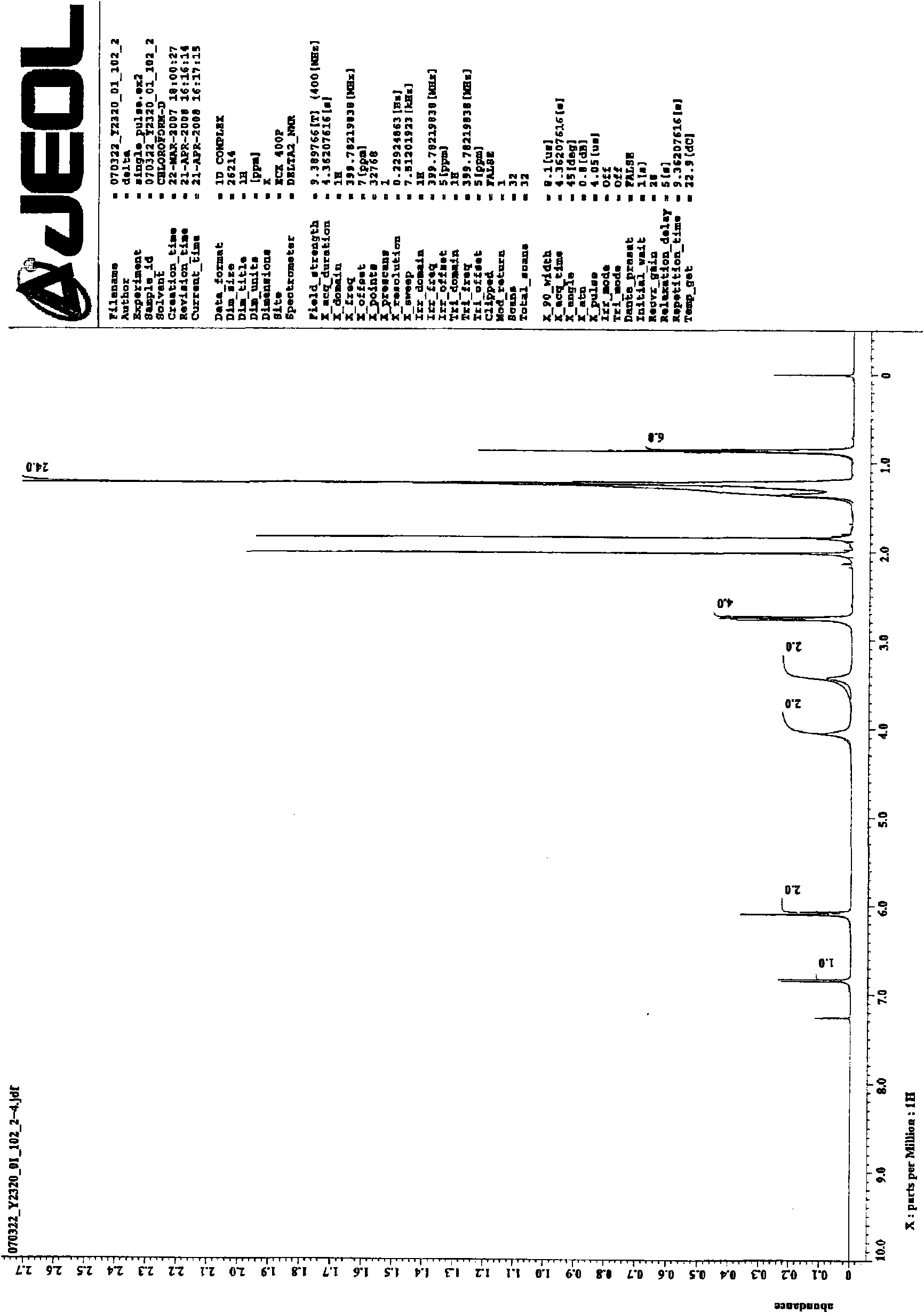

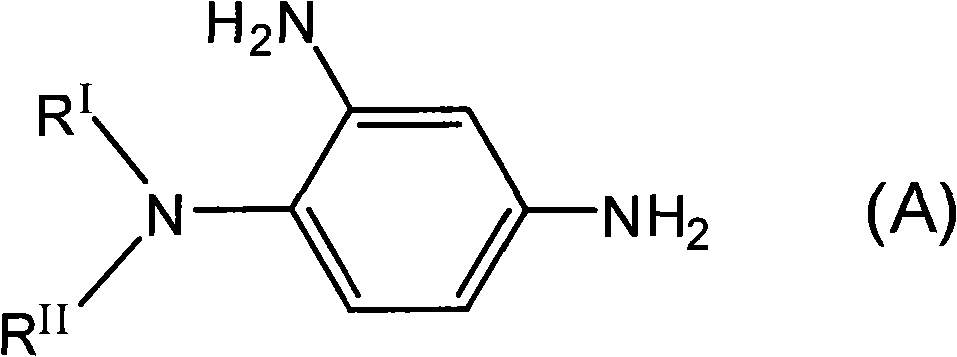

[0130] According to the following synthetic scheme 1, N,N-dioctyl-1,2,4-benzenetriamine was synthesized.

[0131]

[0132] Synthetic route 1

[0133] Under a nitrogen atmosphere, in a 300ml three-necked flask, 11.2g (0.06mol) of 2,4-dinitrofluorobenzene, 10.0g (0.066mol) of cesium fluoride, 14.5g (0.6mol) of di-n-octyl The amines were mixed, 60 ml of dimethyl sulfoxide was added thereto, and stirred to obtain a solution. This solution was heated and stirred at 110° C. under nitrogen for 6 hours to perform a reaction. After the reaction, 200 ml of chloroform was added to the reaction mixture, extracted and washed with 100 ml of ion-exchanged water for 4 times. After the organic layer was dehydrated with magnesium sulfate, it was removed by filtration. The filtrate was concentrated and the solvent was further removed to yield 23.7 g of the dinitro intermediate.

[0134] Then, under a nitrogen atmosphere, add 12.2g (0.03 moles) of the dinitro intermediate synthesized abo...

Synthetic example 2

[0138] 98 g (0.50 mol) of 1,2,3,4-cyclobutanetetracarboxylic dianhydride as tetracarboxylic dianhydride and 109 g (0.50 mol) of pyromellitic dianhydride, 4,4' as diamine - 198g (1.0 mole) of diaminodiphenylmethane was dissolved in a mixed solvent of 230g N-methyl-2-pyrrolidone and 2060g γ-butyrolactone, and after reacting for 3 hours at 40°C, 1350g γ-butyrolactone was added lactone to obtain about 4000 g of a solution containing 10% by weight of polyamic acid (A-1). The solution viscosity of this solution was 125 mPa·s.

Synthetic example 3

[0140] 196 g (1.0 mol) of 1,2,3,4-cyclobutanetetracarboxylic dianhydride as tetracarboxylic dianhydride, 2,2'-dimethyl-4,4'-diamino as diamine Biphenyl 212g (1.0 mole) is dissolved in the mixed solvent that 370g N-methyl-2-pyrrolidone and 3300g gamma-butyrolactone form, after carrying out 3 hours reaction at 40 ℃, obtain containing polyamic acid (A-2 ) solution about 4000g. The solution viscosity of this solution was 160 mPa·s.

[0141]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Solution viscosity | aaaaa | aaaaa |

| Solution viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com