High temperature and high pressure radiation heat flow meter

A high-temperature, high-pressure, heat flow meter technology, applied in calorimeters, measuring heat, measuring devices, etc., can solve problems that affect the measurement accuracy, influence, and failure to detect radiation heat flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

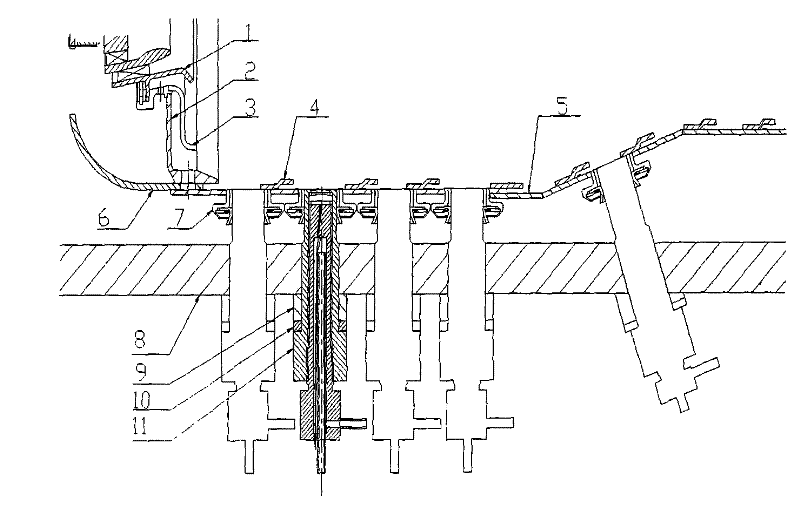

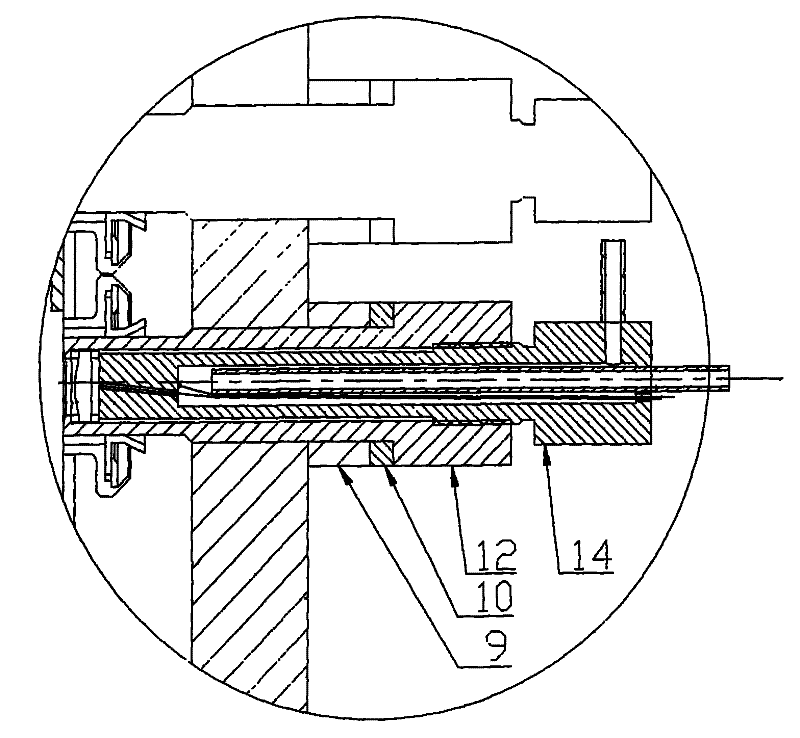

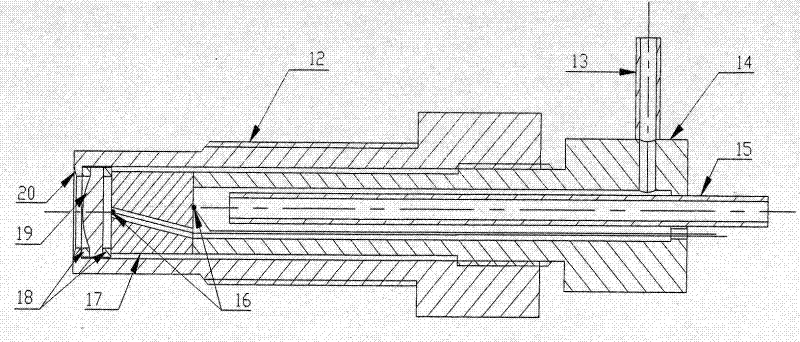

[0024] Such as figure 1 As shown, for a typical structure of a combustion chamber, the heat release process of the working fluid combustion mainly occurs in the area surrounded by the wall surface 5 of the combustion chamber flame tube, and the highest temperature in the combustion area can reach 2500K or even higher. Therefore, the wall surface is surrounded by Ablation is the most common form of flame tube damage in the combustor, in order to more effectively protect the wall of the combustor flame tube from heat. Accurate heat transfer data on the wall of the combustion chamber is required, including the specific conditions of radiation, convection, and heat conduction. Radiation heat transfer has been difficult to describe accurately due to its complex mechanism. In order to accurately measure the radiant heat flow on the wall surface of the combustion chamber flame tube, the designed radiant heat flow meter is installed at the characteristic point through the installation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com