Chloroacetic acid producing method and reaction equipment thereof

A reaction equipment, the technology of chloroacetic acid, applied in the preparation of carboxylates, chemical instruments and methods, preparation of organic compounds and other directions, can solve the problems of inconvenient product separation, affect product quality, increase processing costs, etc., and achieve environmental protection. , improve the reaction speed and selectivity, the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

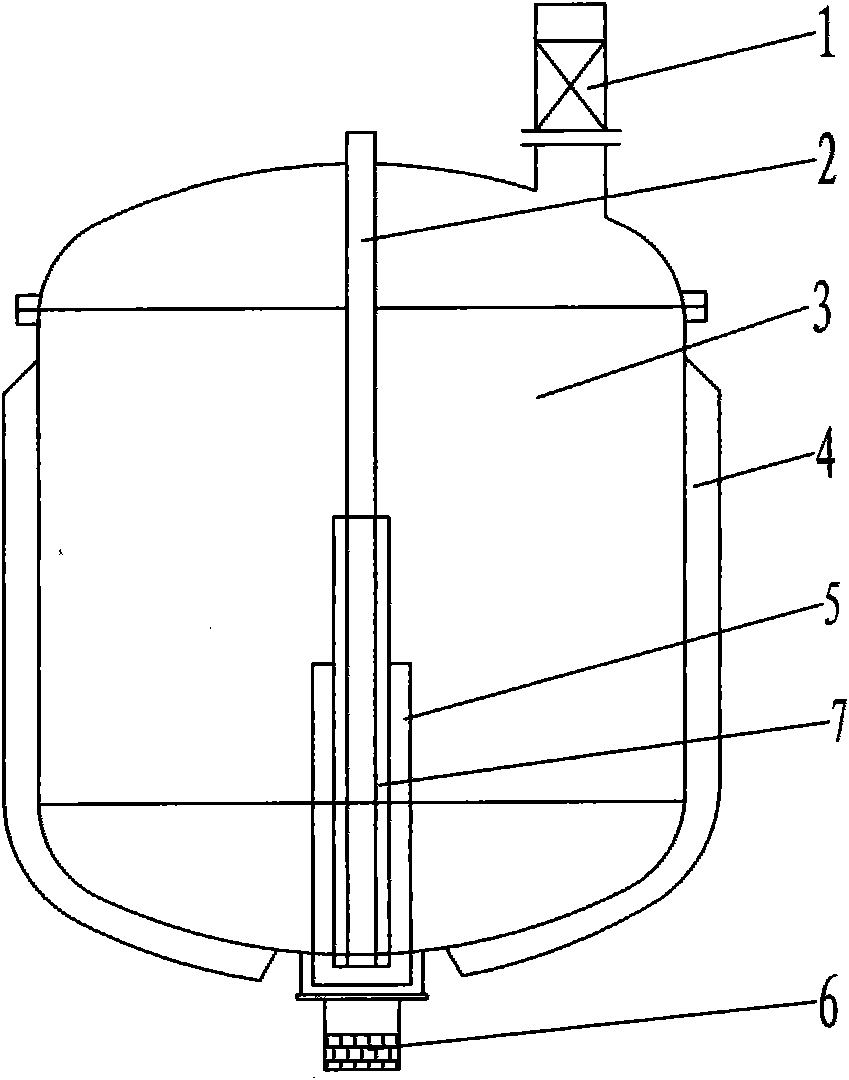

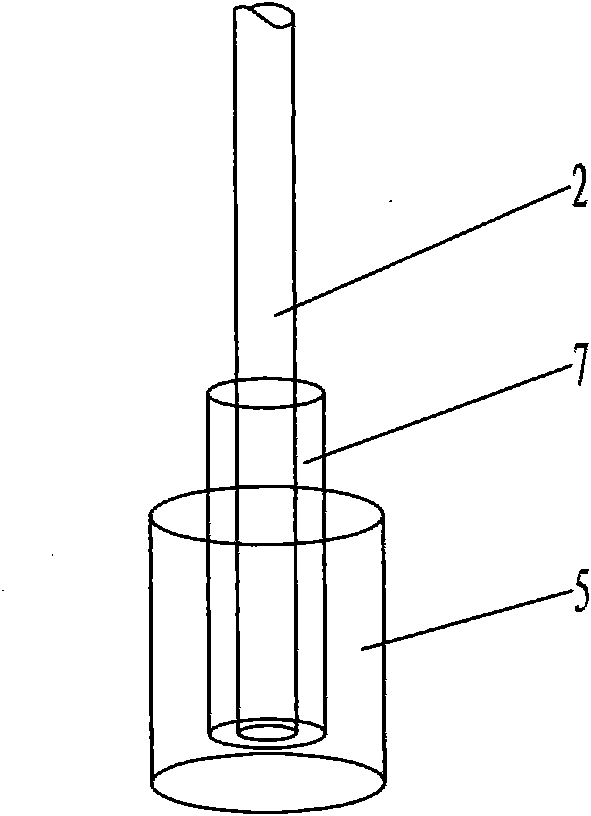

[0015] The reaction equipment of producing chloroacetic acid of the present invention is as figure 1 As shown, it includes a reaction kettle 3 with an enamel lining, a reflux condenser 1, and a chlorine gas pipe 2 is arranged in the reaction kettle. Glass tube, the outside of chlorine gas pipe has concentric deflector 5, and deflector is a circular glass tube, and deflector is fixedly installed in the bottom of chlorine gas pipe, and the lower end of deflector lower end is slightly longer than the lower end of chlorine gas pipe and reinforcing pipe. The outer layer of the reaction kettle is provided with a temperature control jacket 4 for adjusting the temperature of the reaction kettle, and the medium used is steam or water. A microwave generator 6 is installed at the lower opening of the reactor, and the emitter of the microwave generator passes through the polytetrafluoroethylene plate on the wall of the reactor towards the lower end of the internal deflector 5 of the react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com