Method for extracting phenazine from RT base production waste

A technology of base and phenazine, which is applied in the field of extracting useful substances, can solve problems such as waste, achieve high production efficiency, reduce production costs, and increase industrial utilization value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

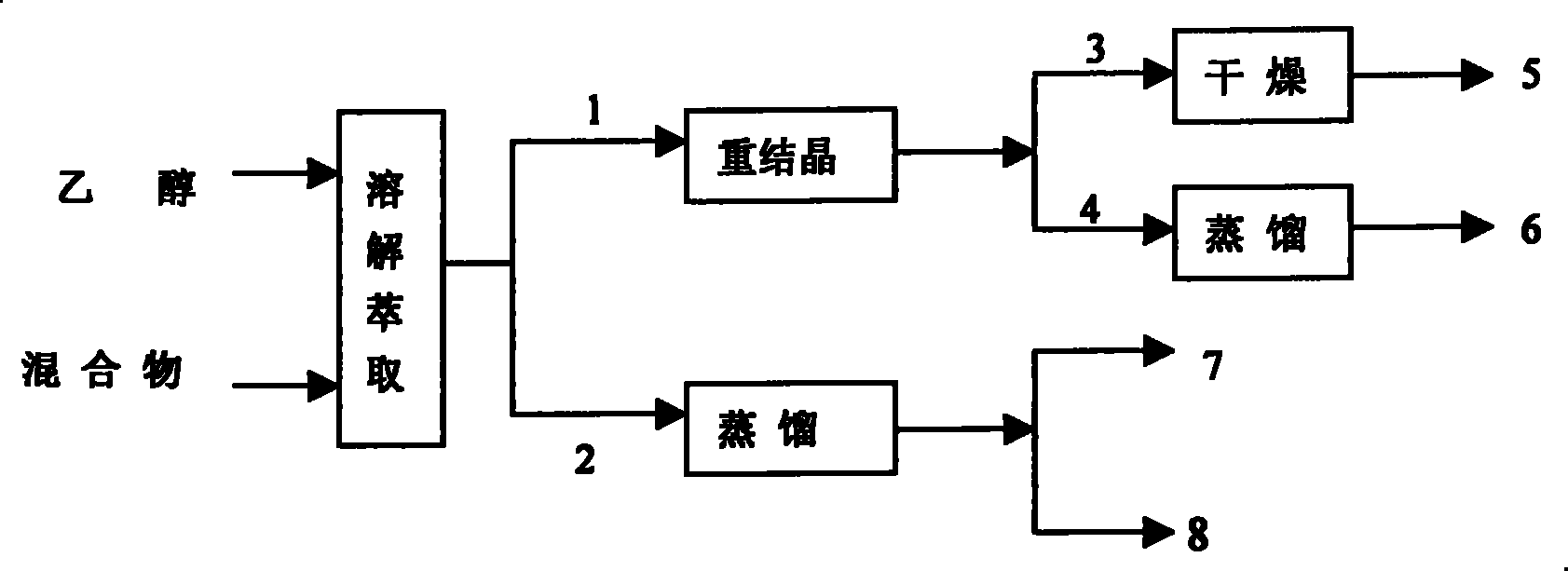

Image

Examples

Embodiment 1

[0019] Add a certain amount of ethanol into the dissolving tank, weigh 1kg RT base waste and add it to the filter cloth of the dissolving extraction tank, first immerse in ethanol for dissolving and extracting for 20 minutes, then raise the filter cloth above the liquid surface, and spray with 2000ml ethanol Rinse the solid insolubles, and centrifugally filter the extracted solid phase before entering the crude phenazine storage tank.

[0020] Add the crude phenazine to the heating kettle of the heating reflux device, add ethanol in a ratio of 1:6 to 1:7 (g:ml) through a meter, heat to 80°C, dissolve and reflux for 0.5 to 1.0 hours, and dissolve the phenazine dissolve. Then filter the solution while it is hot to remove insoluble impurities, put the filtrate into a crystallization tank and slowly cool down to crystallize for 1 to 2 hours, and obtain needle-shaped crystal phenazine, which is separated by centrifugal filtration, and the filter cake is dried in a drying oven, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com