Halogen-free flame retarding epoxy resin composition

A technology of epoxy resin and composition, which is applied in the field of halogen-free flame-retardant epoxy resin composition, can solve the problems of poor heat resistance and dielectric properties of the composition, and achieve improved heat resistance and excellent flame retardancy , the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

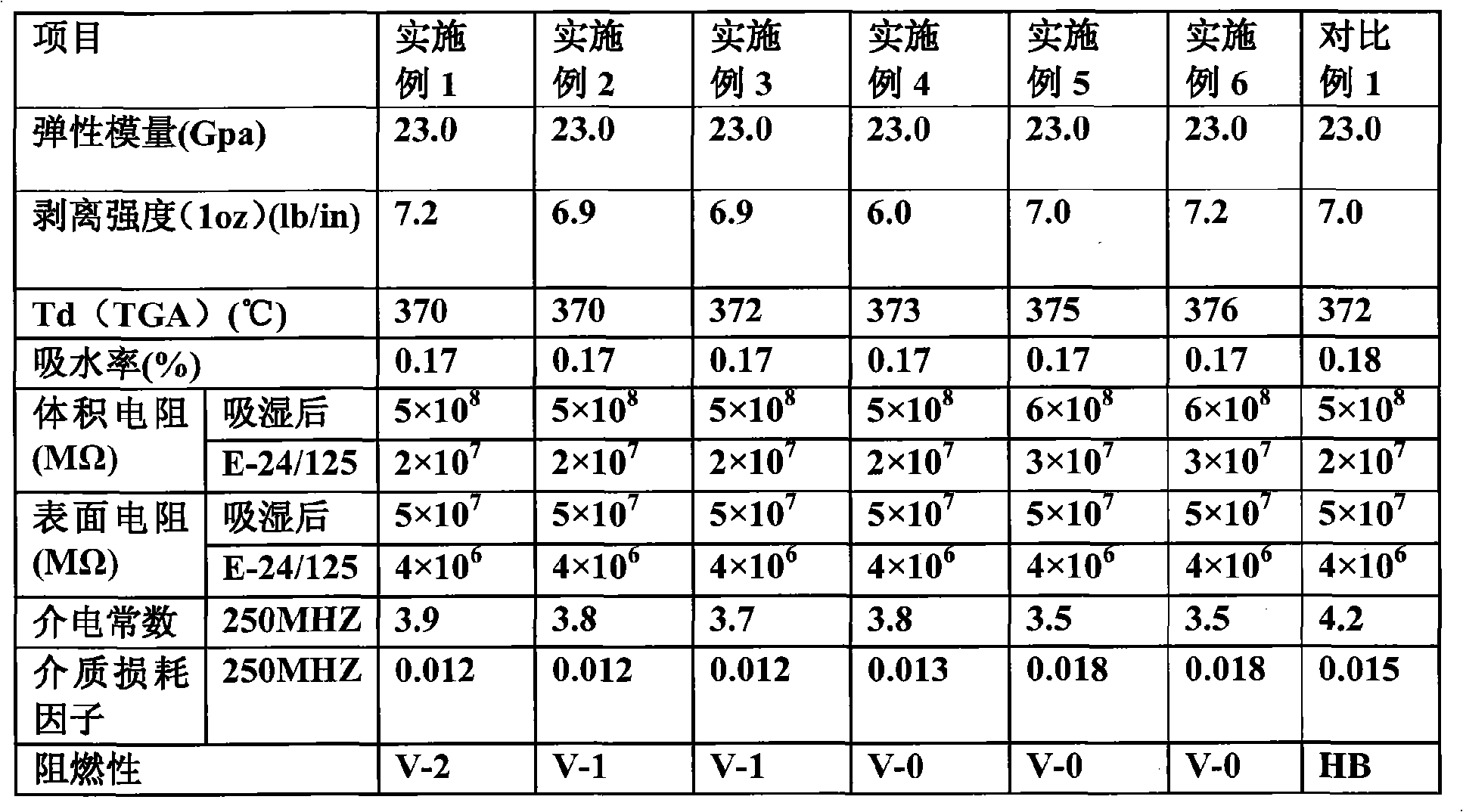

Embodiment 1

[0018] The halogen-free flame-retardant epoxy resin composition according to this embodiment is uniformly stirred by the following proportioning components:

[0019] 100 parts by weight of phosphorus-containing epoxy resin, model 92547 (01), solid content 60%, phosphorus content 2%;

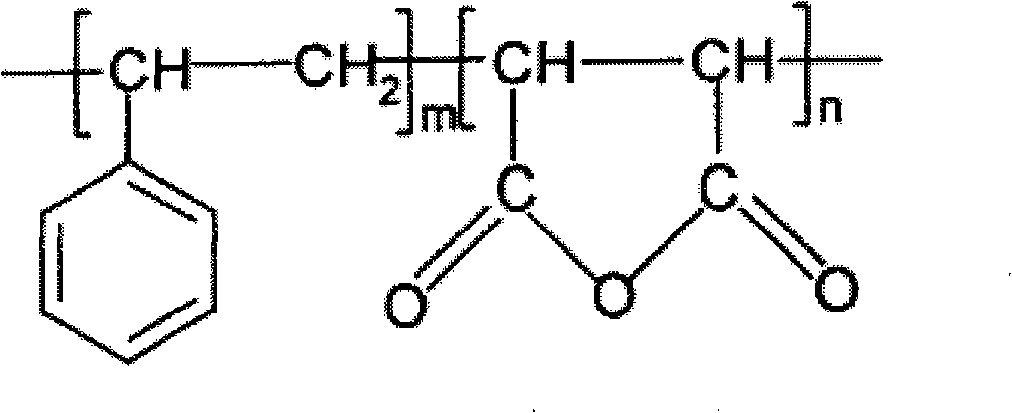

[0020] 100 parts by weight of styrene-maleic anhydride copolymer (m / n=1, Mw=2000);

[0021] 0.1 parts by weight of 2-methylimidazole.

Embodiment 2

[0023] The halogen-free flame-retardant epoxy resin composition according to this embodiment is uniformly stirred by the following proportioning components:

[0024] 100 parts by weight of phosphorus-containing epoxy resin, model 92547 (03), solid content 60%, phosphorus content 4%;

[0025] 100 parts by weight of styrene-maleic anhydride copolymer (m / n=1, Mw=2000);

[0026] 0.1 parts by weight of 2-methylimidazole.

Embodiment 3

[0028] The halogen-free flame-retardant epoxy resin composition according to this embodiment is uniformly stirred by the following proportioning components:

[0029] 100 parts by weight of phosphorus-containing epoxy resin, model 92547 (05), solid content 60%, phosphorus content 4.7%;

[0030] Styrene-maleic anhydride copolymer (m / n=4, Mw=3000) 125 parts by weight;

[0031] 0.1 parts by weight of 2-methylimidazole.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mw | aaaaa | aaaaa |

| Mw | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com