Light coated white craft paper and method for manufacturing same

A kraft cardboard and white surface technology, which is applied in the direction of coated paper base paper, coating, paper, etc., can solve the problems of high smoothness, aggravated papermaking pollution, and easy tearing of paper sheets, so as to improve smoothness and gloss , reduce surface roughness, and reduce the effect of paper wool problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

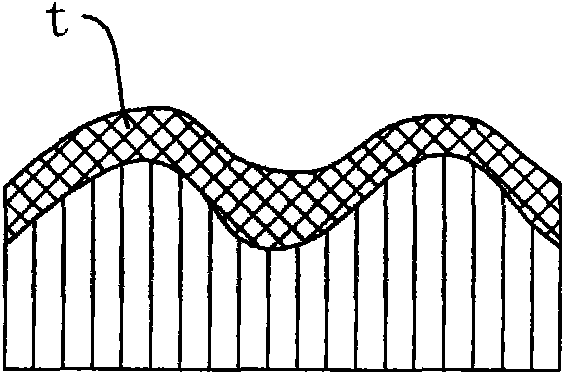

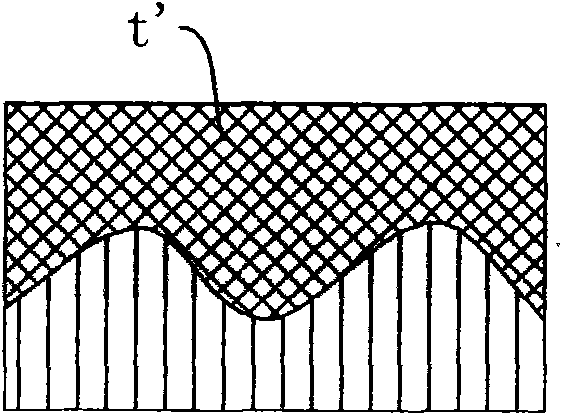

Image

Examples

Embodiment 1

[0023] 1. Pulping

[0024] a. Beat the wood pulp to a degree of 40-50°SR to obtain the surface layer pulp.

[0025] b. Beat recycled old books, old newspapers, and office waste paper to a beating degree of 45-55°SR to prepare lining layer slurry.

[0026] c. Beat the OCC slurry to a beating degree of 30-40°SR to prepare the core layer slurry.

[0027] d. Beat the OCC slurry to a beating degree of 30-40°SR to prepare the bottom layer slurry.

[0028] 2. Coating preparation

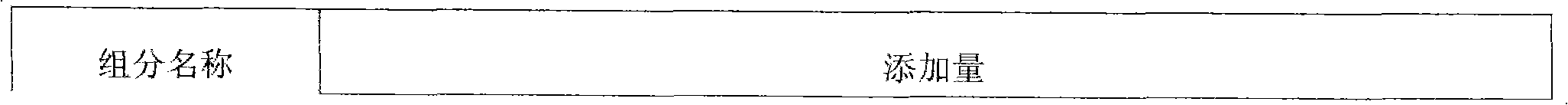

[0029] Coating formula: see Table 1.

[0030] Table 1

[0031]

[0032]

[0033] In Table 1, the calcium carbonate is preferably heavy calcium carbonate, the average particle diameter of the fine-grained kaolin is 0-2 μm, and the exfoliated kaolin is obtained by peeling fine-grained kaolin with an average particle diameter less than 2 μm. For ordinary fine-grained kaolin, the diameter-thickness ratio of exfoliated kaolin is larger, so the covering effect is better.

[0034] After stirring the ab...

Embodiment 2

[0049] Embodiment 2 is basically the same as embodiment 1, and its difference is the formula of coating, and the coating formula of embodiment 2 is shown in Table 1.

[0050] Quantitative 150g / m made by the above process 2 See Table 2 for the technical indicators of light-coated white-faced kraftboard.

Embodiment 3

[0052] Embodiment 3 is basically the same as embodiment 1, and its difference lies in the formula of coating, and the coating formula of embodiment 3 is shown in Table 1.

[0053] Quantitative 170g / m produced by the above process 2 See Table 2 for the technical indicators of light-coated white-faced kraftboard.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com