Production process for easy decontamination shrink-proof bleaching liner

A production process and easy decontamination technology, applied in bleaching products, clothing, applications, etc., can solve problems such as unfavorable environmental protection and large fabric damage, and achieve the effect of simplifying operation, reducing fabric damage, and reducing fabric damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

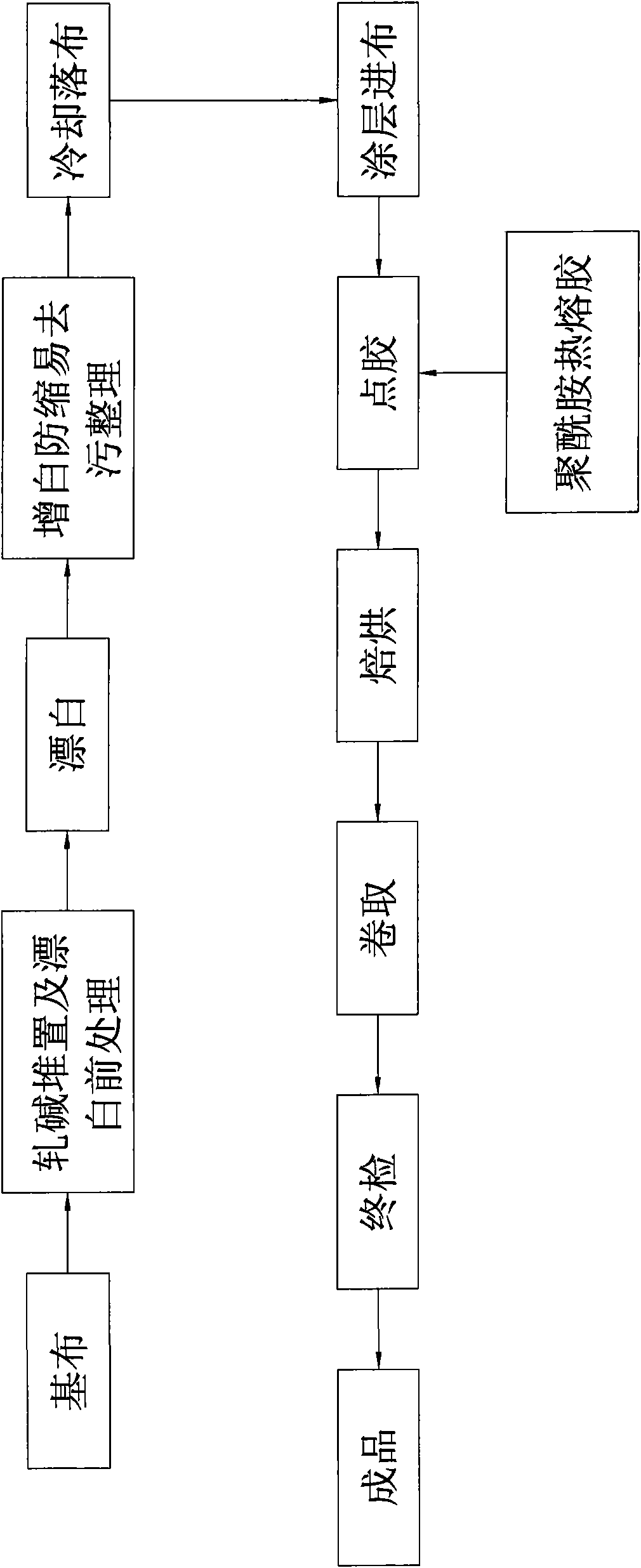

[0018] refer to figure 1 It is an embodiment of the production process of the easy decontamination and anti-shrinkage bleached lining of the present invention, and the production process of the easy-decontamination and anti-shrinkage bleached lining comprises the following steps:

[0019] A. Immediately after singeing the base fabric, roll alkali to extinguish the fire and cool it down. The NaOH in the alkali solution is 10-15g / L, and the environmental refining agent is 6g / L. After keeping warm and moisturizing for 10-12 hours, perform flat washing and desizing above 95°C ;

[0020] B. Bleaching: multifunctional refining enzyme 2.5-3.0g / L in the bleaching solution, 6-8ml / L hydrogen peroxide at a concentration of 27.5%-30%, bath ratio 1:8-1:10, bleaching time 30-45min;

[0021] C. Whitening, anti-shrinkage finishing and decontamination finishing in the same bath: SR antifouling agent 50g / L, ultra-low formaldehyde resin 80g / L, magnesium chloride 13g / L, whitening agent 8-10g / L, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com