Method for preparing aluminum borate nanowire

A nanowire and aluminum borate technology, which is applied in the field of preparation of aluminum borate nanowires, can solve the problems of inconsistent product morphology, harsh preparation conditions, and dispersed dimensional distribution, and achieve uniform size distribution, complete product crystal form, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

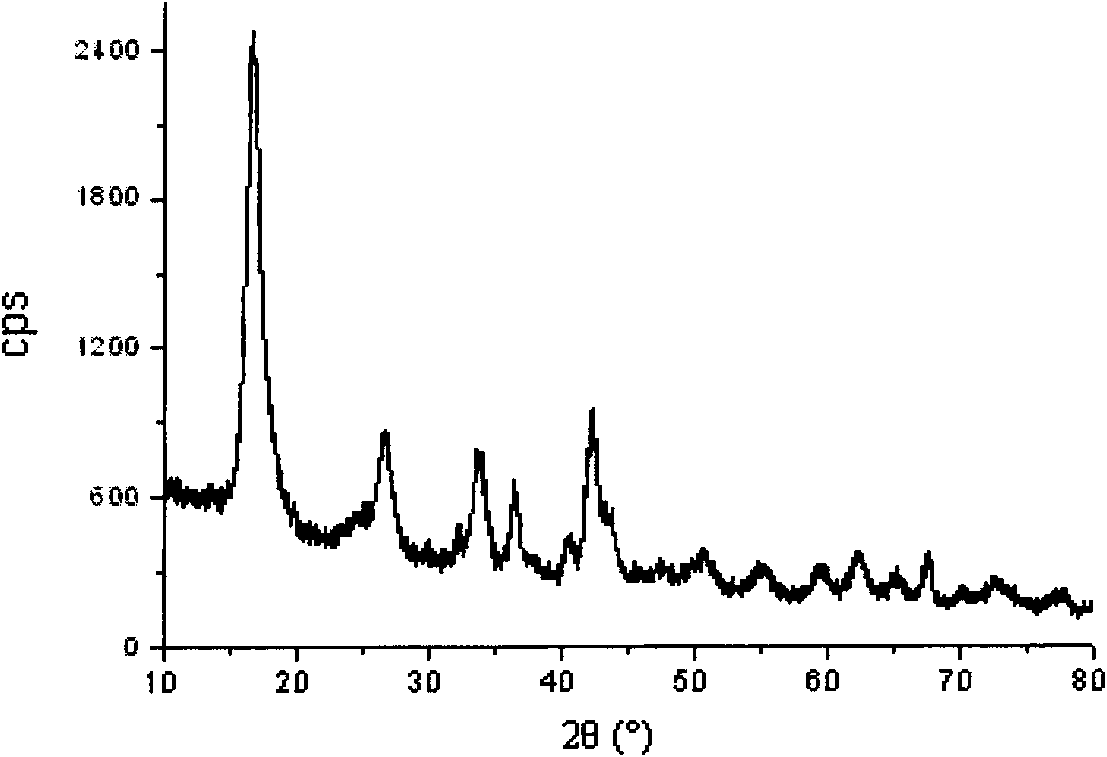

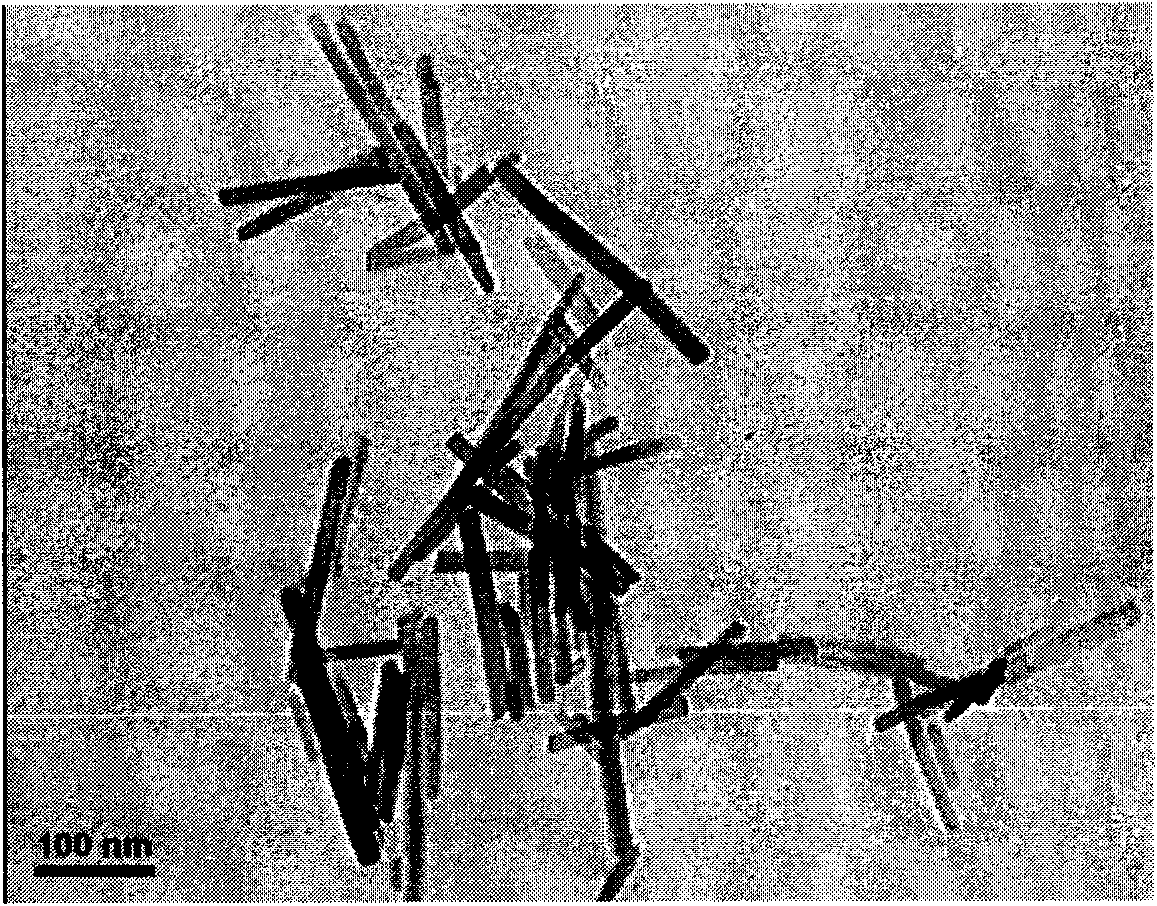

Embodiment 1

[0017] Weigh 3.75g Al(NO 3 ) 3 9H 2 O was dissolved in 100ml of distilled water, stirred magnetically for 2 hours to obtain mixed solution A, weighed 1.87g of boric acid and 5.62g of glucose, and stirred in 100ml of distilled water for 1 hour to obtain solution B, slowly added solution B to mixed solution A After mixing evenly, dry at 150°C to obtain light yellow xerogel. The gel was calcined at 750°C for 4 hours to form a white powder, which was washed three times with hot water and dried at 60°C to obtain Al 4 B 2 o 9 Nanowires, Al detected by TEM and XRD 4 B 2 o 9 It is a nanowire with a single crystal structure, the size of the nanowire is uniformly distributed, the diameter is 25nm, and the length is 200-300nm.

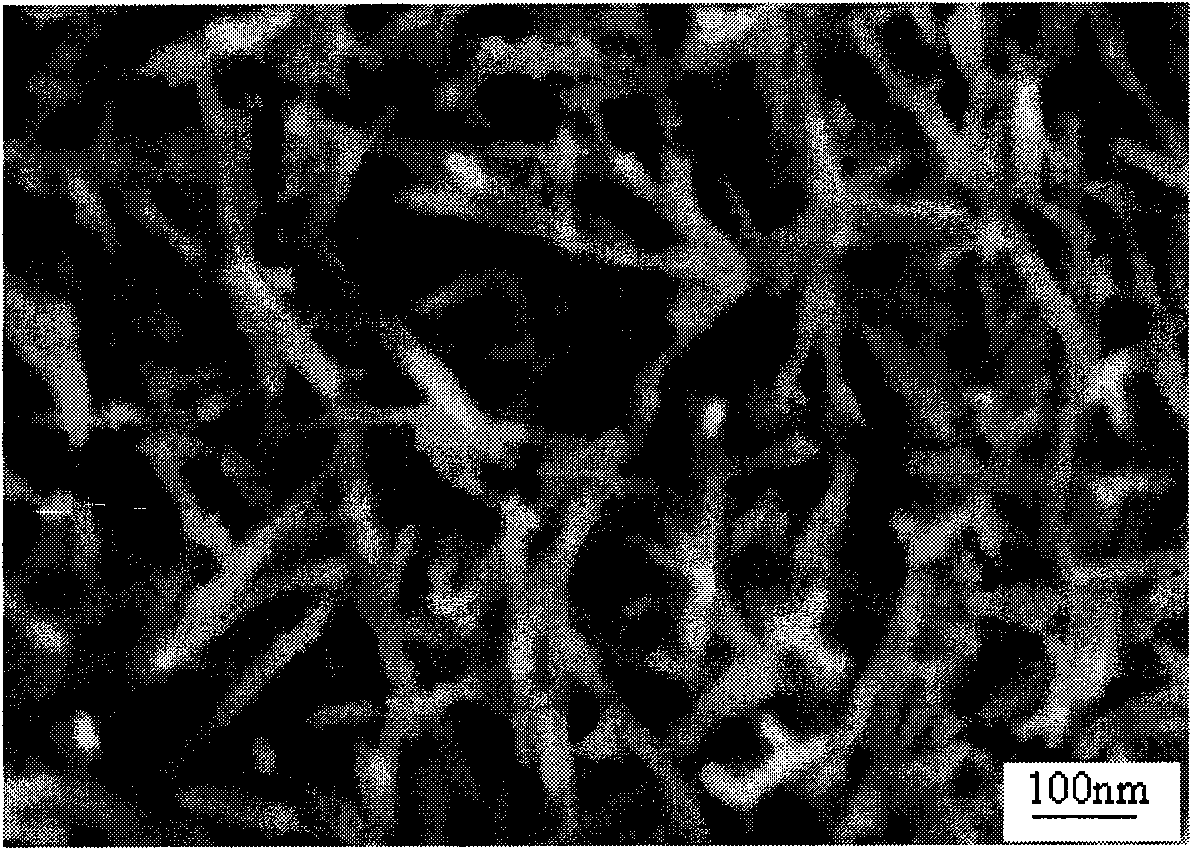

Embodiment 2

[0019] Weigh 3.75gAl(NO 3 ) 3 9H 2 Dissolve O in 200ml distilled water, stir magnetically for 24 hours to obtain mixed solution A, weigh 1.25g boric acid and 5.0g sucrose, mix them uniformly in 200ml distilled water for 6 hours to obtain solution B, slowly add solution B to mixed solution A After mixing evenly, evaporate at 120°C for 8 hours to obtain dark brown xerogel. The gel was calcined at 1200°C for 2 hours to form a white powder, which was washed with hot water for 5 times and dried at 100°C to obtain Al 18 B 4 o 33 Nanowires, Al detected by TEM and XRD 18 B 4 o 33 The nanowire is a single crystal structure with a diameter of 50-90 nm and a length of 2-3 μm.

Embodiment 3

[0021] Weigh 2.46g of aluminum sec-butoxide and dissolve it in 100ml of distilled water, stir magnetically for 36 hours to obtain mixed solution A, weigh 1.24g of boric acid and 3.7g of glucose, and magnetically stir in 100ml of distilled water for 1 hour to obtain solution B. Slowly add it dropwise into the mixed solution A, mix well and dry at 100°C to obtain a light yellow xerogel. The gel was calcined at 750°C for 4 hours to form a white powder, which was washed three times with hot water and dried at 60°C to obtain Al 4 B 2 o 9 Nanowires. Al was detected by TEM and XRD 4 B 2 o 9 The nanowire is a single crystal structure with a diameter of about 30nm and a length of 100-200nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com