Biochemical treatment and sedimentation integrated backflow type active sludge biochemical treatment device

A biochemical treatment device, activated sludge technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, sustainable biological treatment, etc. High-pressure air, limiting the depth of aerobic biochemical pools, etc., to reduce the floor space, expand the water depth, and reduce the sludge content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

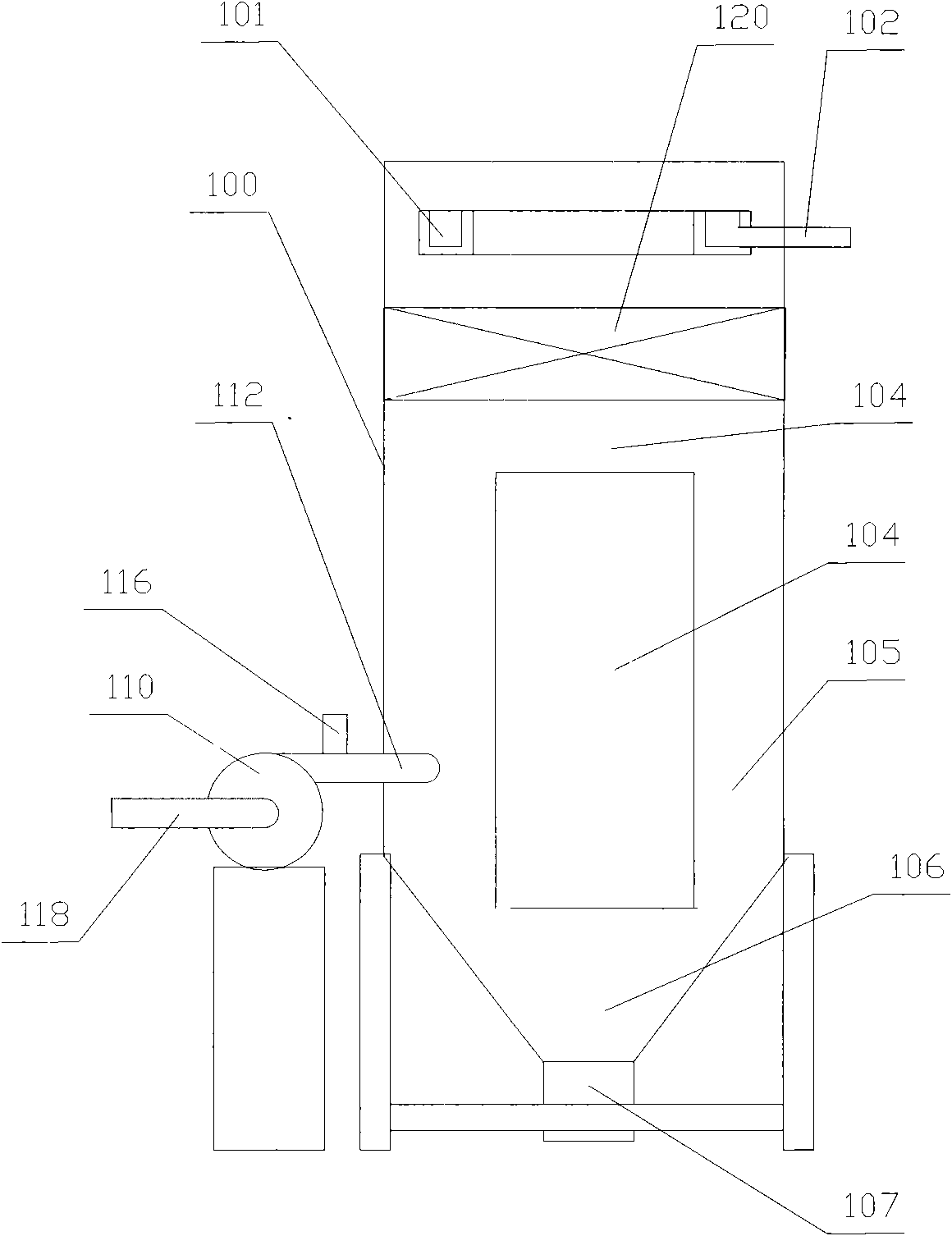

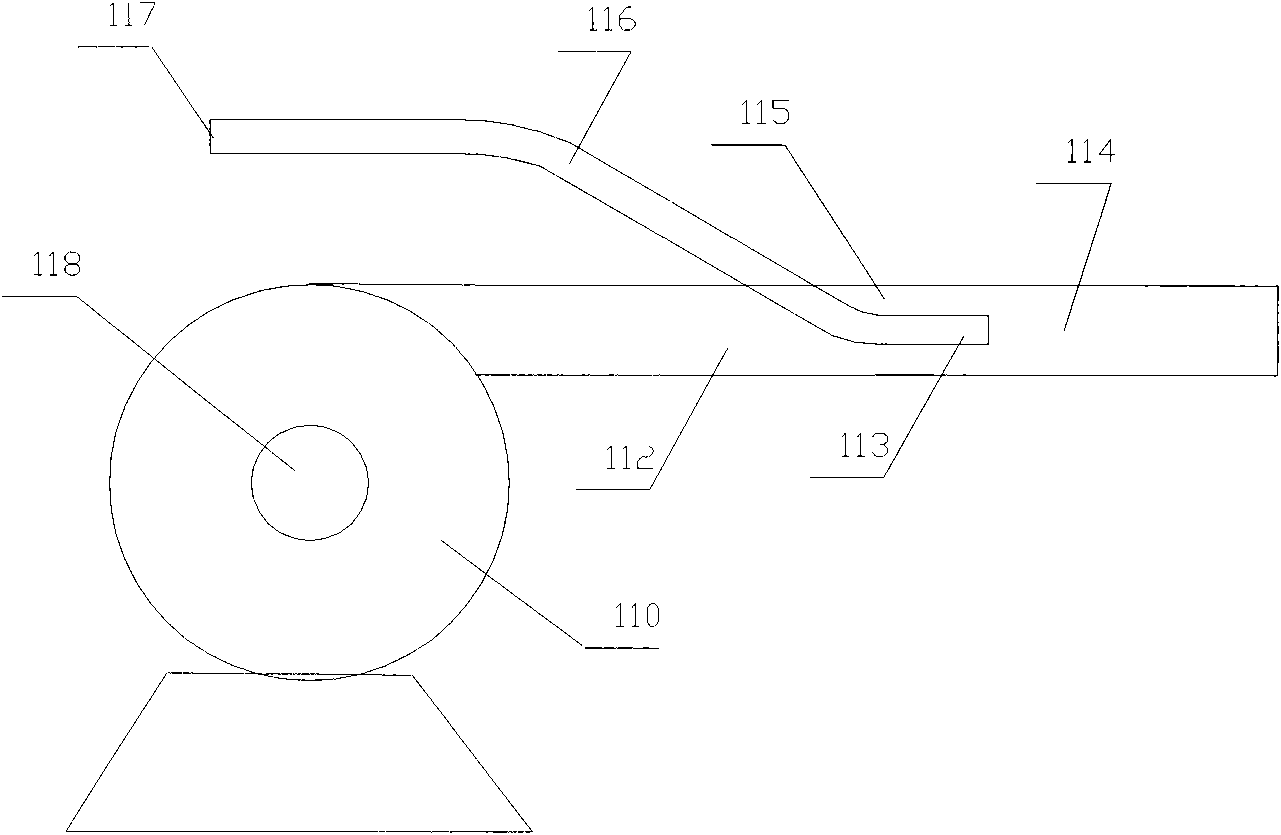

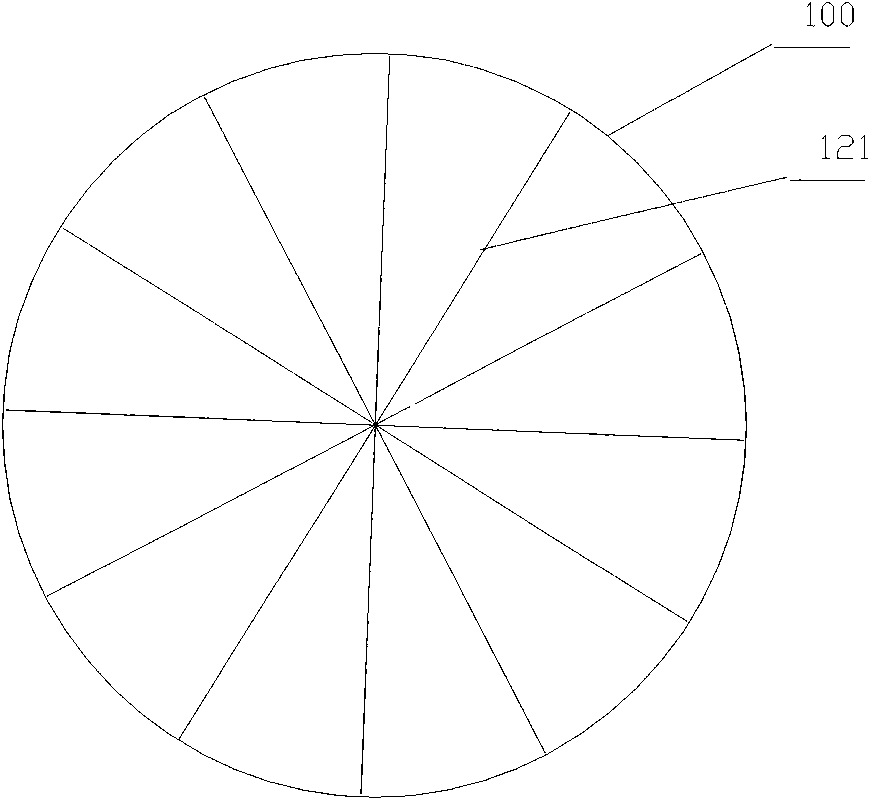

[0010] see figure 1 and 2 , the present invention relates to a biochemical and sedimentation integrated reflux activated sludge biochemical treatment device, comprising a cylindrical shell 100 and a high-efficiency aeration device, the upper part of the shell is provided with an annular The overflow tank 101 and the derotation device 120 located below the annular overflow tank, the lower part of the shell is in the shape of an inverted frustum, the bottom is provided with a sludge discharge port 107, and a return cylinder 104 with open upper and lower ends is arranged in the middle. There is a space between the upper end of the return cylinder and the top of the shell to form the settlement overflow area 103, and there is a space between the lower end and the bottom of the shell to form the sludge area 106, and the outer wall is separated from the inner wall of the shell. There is an interval to form a swirl channel 105 between them. The jet aeration device includes a high-pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com