Preparation method and application for modified zeolite adsorbent

A technology for modifying zeolite and adsorbent, which is applied in chemical instruments and methods, adsorbed water/sewage treatment, other chemical processes, etc., to achieve the effects of high utilization rate, efficient utilization and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

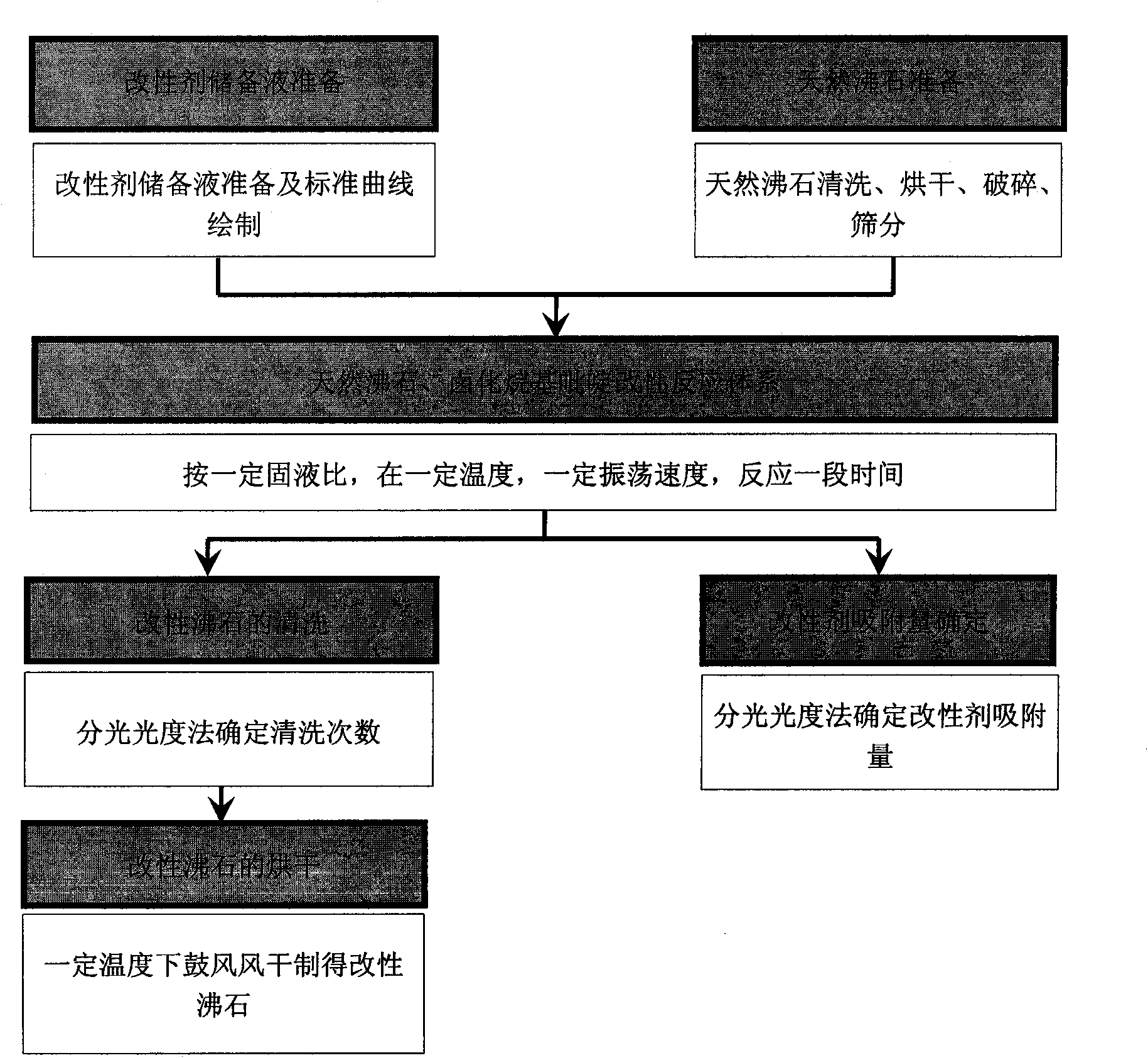

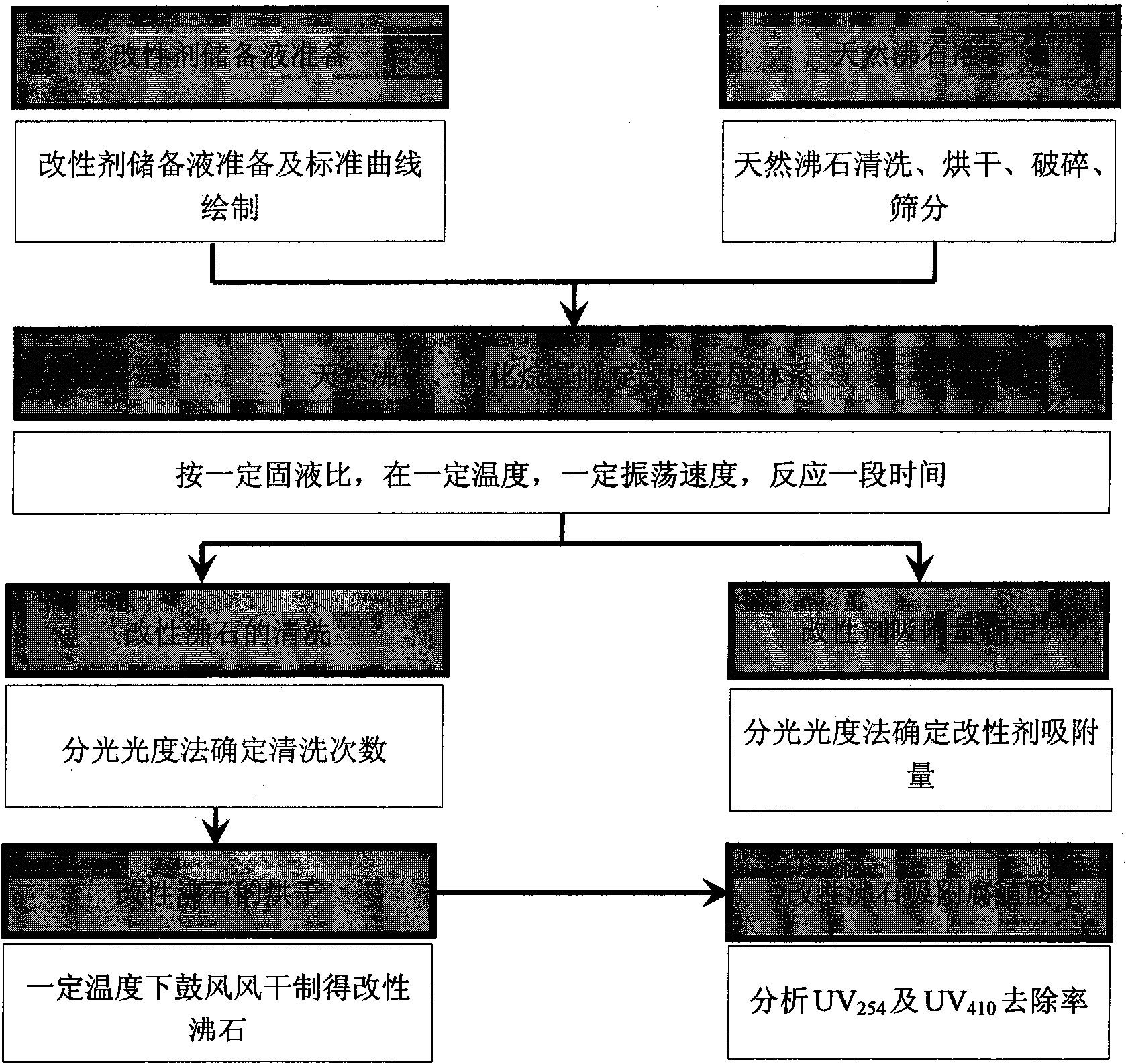

Method used

Image

Examples

Embodiment 1

[0023] (1) Take the natural zeolite, wash it several times with distilled water, air-dry it, crush it, grind it, and pass it through an 80-mesh sieve for later use; the prepared concentration is 50mmol L -1 cetylpyridinium bromide stock solution for use.

[0024] (2) Weigh 9g of ground and sieved zeolite and Erlenmeyer flask, pipette 36ml with a concentration of 50mmol L -1 After cetylpyridinium bromide (CPB) stock solution and zeolite were fully mixed, placed in a 40°C constant temperature water area oscillator and oscillated at 160rpm for 2d, after standing for 2d, centrifuged at 3000rpm, using the ultraviolet spectrometer method (λ = 259nm) to analyze the CPB concentration in the supernatant, calculate the equilibrium concentration according to the CPB standard curve, and obtain the adsorption capacity of CPB as 199.5mmol / g zeolite. Finally, the CPB modified zeolite was washed with distilled water until no CPB was detected in the cleaning supernatant, then placed in a beak...

Embodiment 2

[0027] (1) Take the natural zeolite, wash it several times with distilled water, air-dry it, crush it, grind it, and pass it through an 80-mesh sieve for later use; the prepared concentration is 50mmol L -1 cetylpyridinium bromide (CPB) stock solution for use.

[0028] (2) Weigh 9g of ground and sieved zeolite and Erlenmeyer flask, pipette 63ml with a concentration of 50mmol L -1 After fully mixing the CPB stock solution with zeolite, place it in a constant temperature water area at 40°C and vibrate at 160rpm for 2d, then centrifuge at 3000rpm after standing for 2d, and analyze the concentration of CPB in the supernatant by UV spectrometer (λ=259nm) , the equilibrium concentration was found on the CPB standard curve, and the calculated adsorption capacity of CPB was 329.3mmol / g zeolite. Finally, the CPB modified zeolite was washed with distilled water until no CPB was detected in the cleaning supernatant, then placed in a petri dish for blast drying at 60° C., and the modifie...

Embodiment 3

[0031] (1) Take the natural zeolite, wash it several times with distilled water, air-dry it, crush it, grind it, and pass it through an 80-mesh sieve for later use; the prepared concentration is 50mmol L -1 cetylpyridinium chloride (CPC) stock solution for future use.

[0032] (2) Weigh 9g of ground and sieved zeolite and Erlenmeyer flask, pipette 27ml with a concentration of 50mmol L -1 After fully mixing the CPC stock solution and zeolite, place it in a constant temperature water area at 40°C and vibrate at 160rpm for 2d, then centrifuge at 3000rpm after standing for 2d, and analyze the concentration of CPC in the supernatant by UV spectrometer (λ=259nm). , the equilibrium concentration was found on the CPC standard curve, and the adsorption capacity of CPC was calculated to be 149.85mmol / g zeolite. Finally, the CPC modified zeolite was washed with distilled water until no CPC was detected in the cleaning supernatant, and then placed in a beaker at 60° C. for blast drying, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com