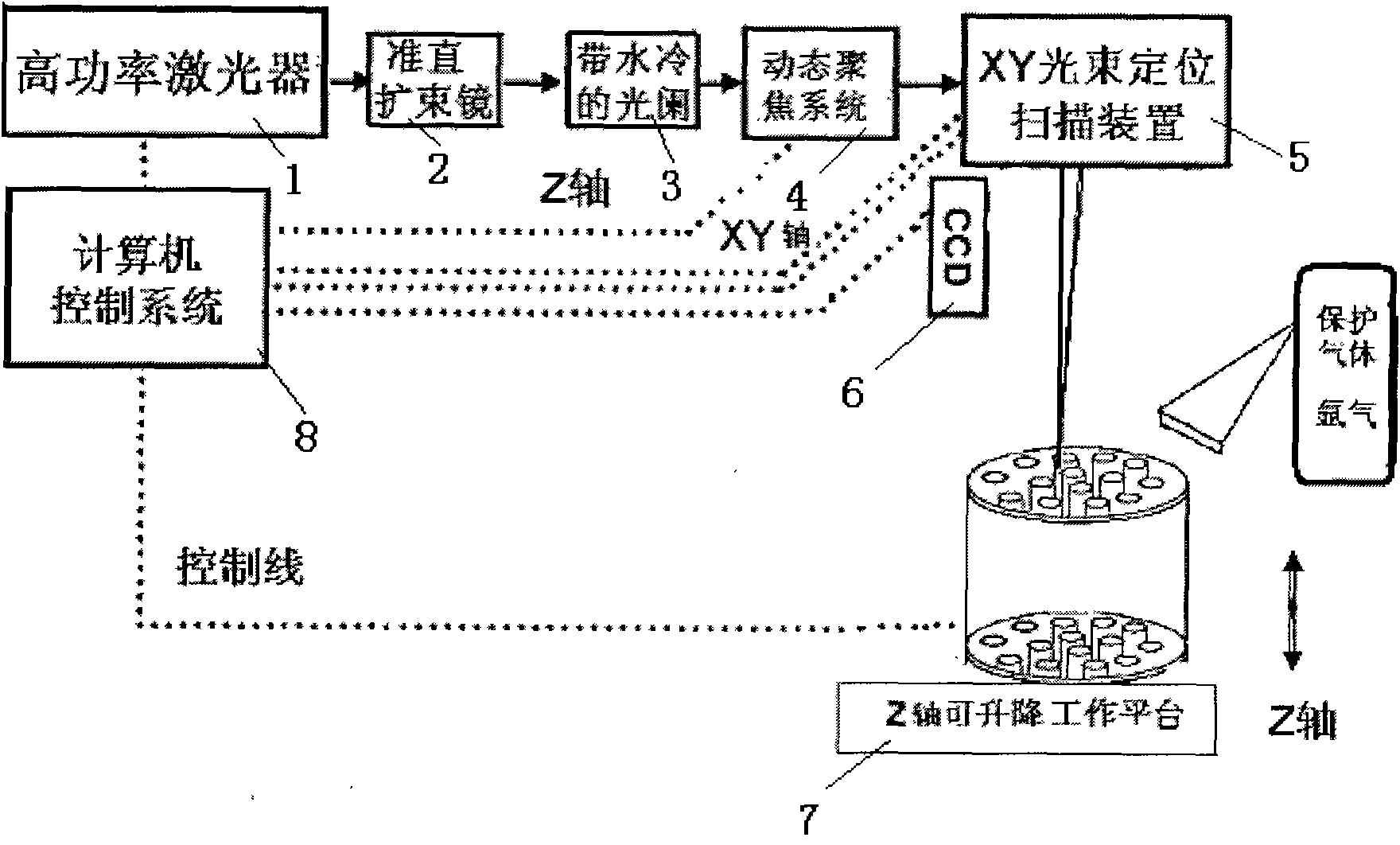

Method and device for welding tube type heat exchanger by using laser scanning

A tube-and-tube heat exchanger, laser scanning technology, applied in the direction of laser welding equipment, welding equipment, tubular objects, etc., can solve the problems of incompatibility, huge equipment, high cost, etc., and achieve wide application value, heat exchange area and heat conduction The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

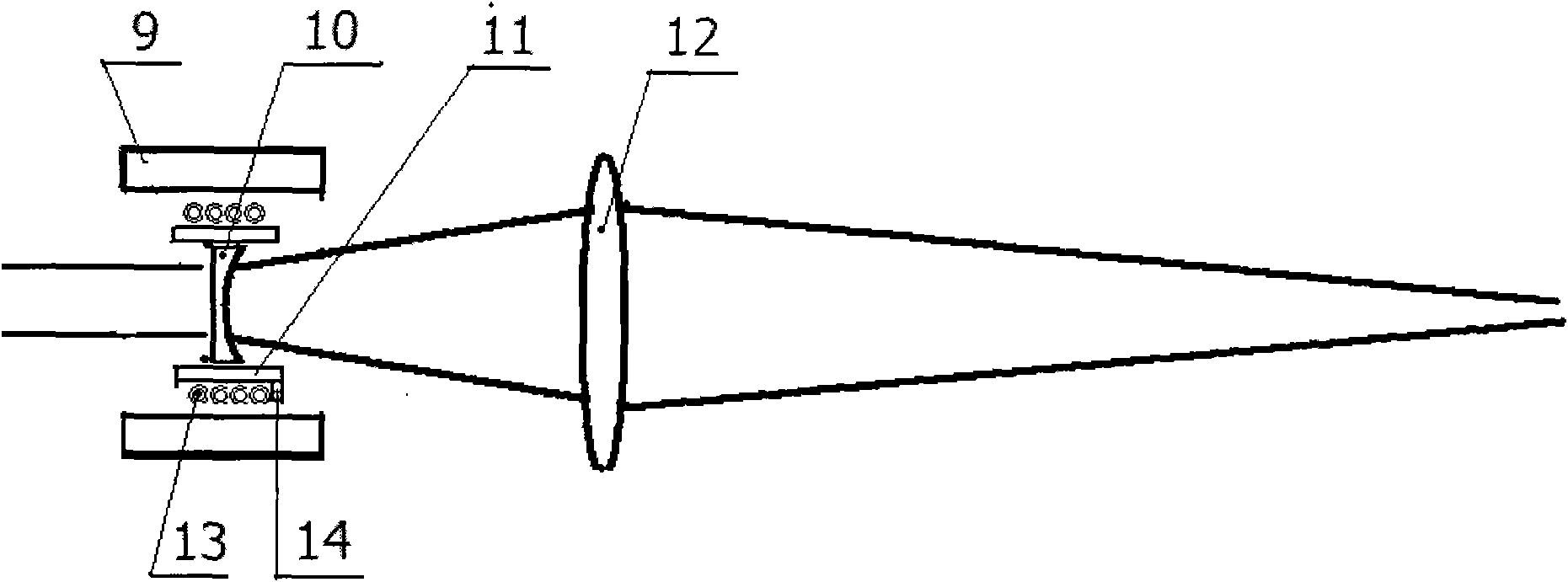

[0024] The high-power laser uses a kilowatt-level carbon dioxide laser with a laser wavelength of 10.6 μm. An industrial-grade carbon dioxide laser with better beam quality can be used, such as Rofin DC350 high-power carbon dioxide laser. The beam expander lens and focus lens used in the dynamic focusing optical system are all processed with high-quality zinc selenide materials. The optical components of the beam expander lens and focus lens must be sputtered to obtain a high-quality carbon dioxide laser 10.6μm wavelength anti-reflection coating to Ensure that the system has certain damage resistance and service life under high-power laser working conditions.

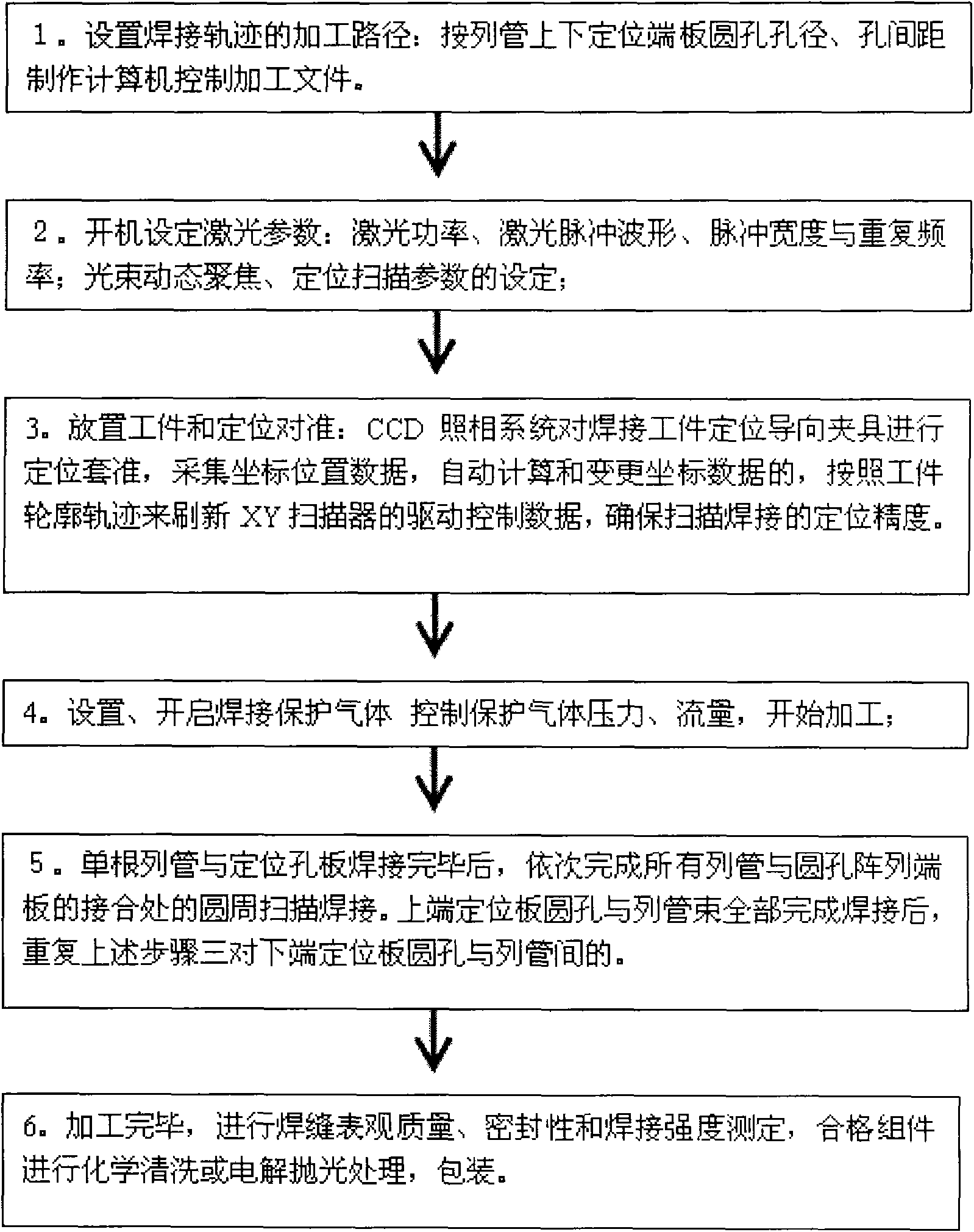

[0025] Set the outer diameter of the stainless steel tubes used in the tube-and-tube heat exchanger, the diameter of the array of round holes on the upper and lower positioning plates, the hole spacing, and the diameter and wall thickness of the tubes, and make computer-controlled processing files:

[0026] According to...

Embodiment 2

[0029]The high-power laser uses a high-power fiber laser. The high-power fiber laser has small size, excellent beam quality, and is maintenance-free. The laser wavelength is 1.06 μm. Industrial-grade high-power fiber lasers produced by IPG or SPI can be selected. The laser power range is 200w- 1000w, due to the good quality of the fiber laser beam, a very fine focused spot can be obtained, the weld seam is more uniform and smooth, and the laser energy is optimized by controlling the beam pulse width modulation. The beam expander lens and focus lens used in the dynamic focusing optical system are all made of high-quality quartz or sapphire materials. The optical components of the beam expander lens and focus lens must be sputtered to obtain a high-quality fiber laser 1.06μm wavelength anti-reflection coating to ensure The system has certain damage resistance and service life under high-power laser working conditions. High-power fiber laser dynamic focus scanning welding is more...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com