Method for preparing copper selenide nanometer material

A technology of nanomaterials and copper selenide, which is applied in the field of preparation of copper selenide nanomaterials, can solve the problems of no nanomaterial reports or technical documents, and achieve the effects of easy promotion, less equipment and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

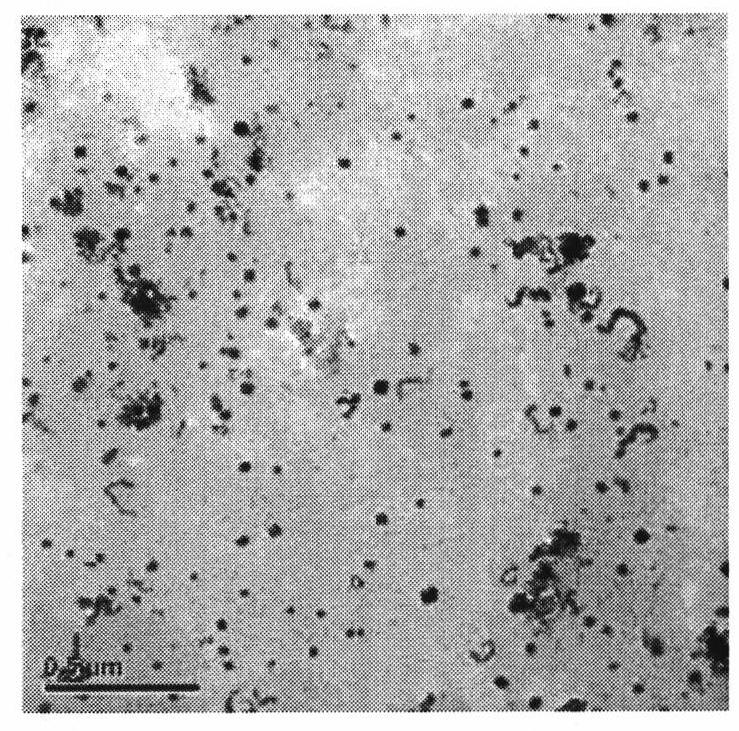

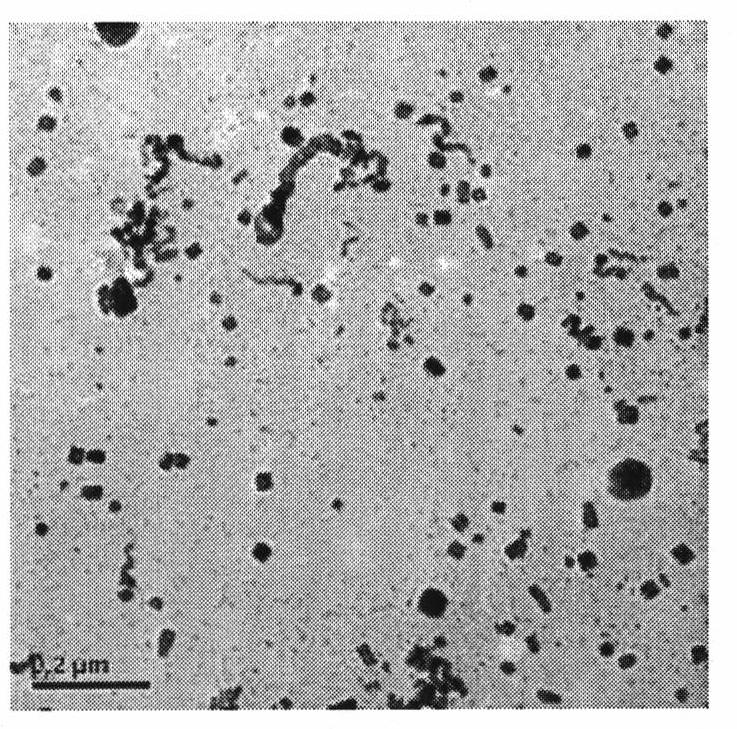

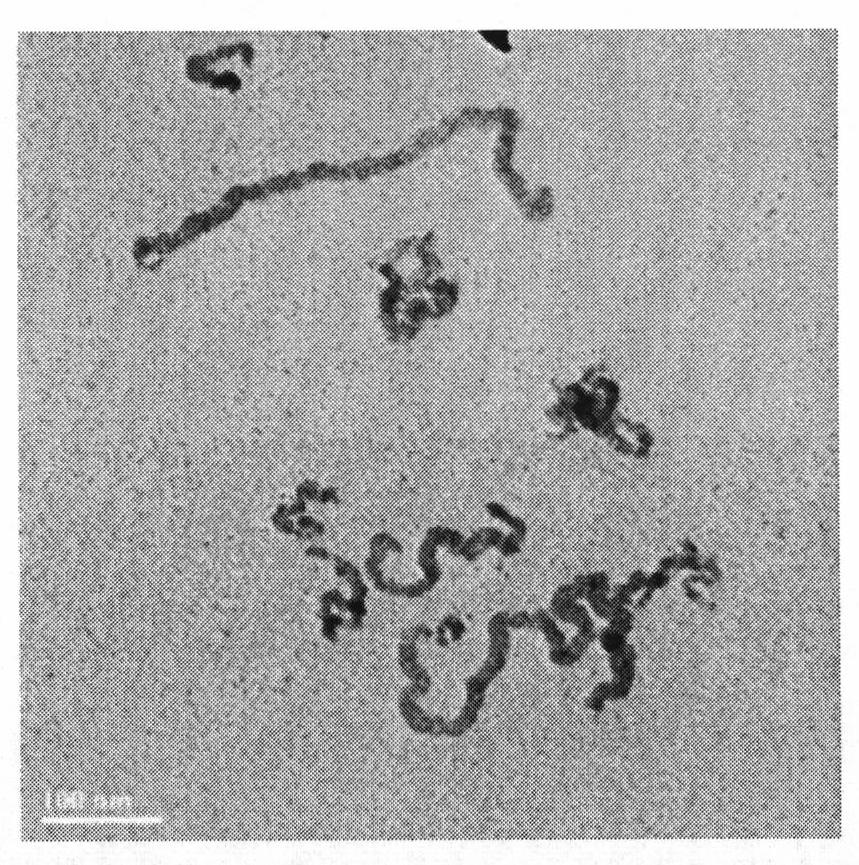

Image

Examples

Embodiment 1

[0021] (a) Weigh 0.630g, add 5mmol of anhydrous sodium sulfite (Na 2 SO 3 ) and 0.395g, the selenium powder of closing 5mmol was dissolved in 200mL distilled water and refluxed 24 hours, made sodium selenosulfate solution;

[0022] (b) Add 5mL of 25mM Cu(NO 3 ) 2 Aqueous solution, and vigorously stirred at room temperature, vacuumed and kept in nitrogen for 2 hours to make copper ion protein mixture;

[0023] (c) Get 5mL of 25mM sodium selenite solution in (a), add in the copper ion protein mixed solution solution in (b) and then stand still after slight stirring to make selenium-copper protein mixed solution;

[0024] (d) Leave the selenium-copper protein mixture at room temperature for 24 hours to complete the reaction, centrifuge at 15,000 rpm for 10 minutes, wash the resulting black solid three times with distilled water and ethanol, and then vacuum-dry it at 30°C After 12 hours, copper selenide nanomaterials were prepared.

Embodiment 2

[0026] (a) Weigh 0.630g, add 5mmol of anhydrous sodium sulfite (Na 2 SO 3 ) and 0.395g, the selenium powder of closing 5mmol was dissolved in 200mL distilled water and refluxed 24 hours, made sodium selenosulfate solution;

[0027] (b) Add 5mL of 25mM Cu(NO 3 ) 2 Aqueous solution, and vigorously stirred at room temperature, vacuumed and kept in nitrogen for 2 hours to make copper ion protein mixture;

[0028] (c) Take 5mL of 25mM Na in (a) 2 SeSO 3 solution, add the copper ion protein mixed solution in (b) and then stand still after slight stirring to make the selenium-copper protein mixed solution;

[0029] (d) Leave the selenium-copper protein mixture at room temperature for 48 hours and then centrifuge it at 15,000 rpm for 10 minutes. The resulting black solid is washed three times with distilled water and ethanol, and then vacuum-dried at 30°C After 12 hours, copper selenide nanomaterials were prepared.

Embodiment 3

[0031] (a) Weigh 0.630g, add 5mmol of anhydrous sodium sulfite (Na 2 SO 3 ) and 0.395g, the selenium powder of closing 5mmol was dissolved in 200mL distilled water and refluxed 24 hours, made sodium selenosulfate solution;

[0032] (b) Add 5mL of 25mM Cu(NO 3 ) 2 Aqueous solution, and vigorously stirred at room temperature, vacuumed and kept in nitrogen for 2 hours to make copper ion protein mixture;

[0033] (c) Take 5mL of 25mM Na in (a) 2 SeSO 3 solution, add (b) in the copper ion protein mixed solution and then stand still after slight stirring to make the selenium-copper protein mixed solution;

[0034] (d) Leave the selenium-copper protein mixture at room temperature for 96 hours and then centrifuge at 15,000 rpm for 10 minutes. The resulting black solid is washed three times with distilled water and ethanol, and then vacuum-dried at 30°C After 12 hours, copper selenide nanomaterials were prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com