High-transparency caesalpinia spinosa glue as well as preparation method and application thereof

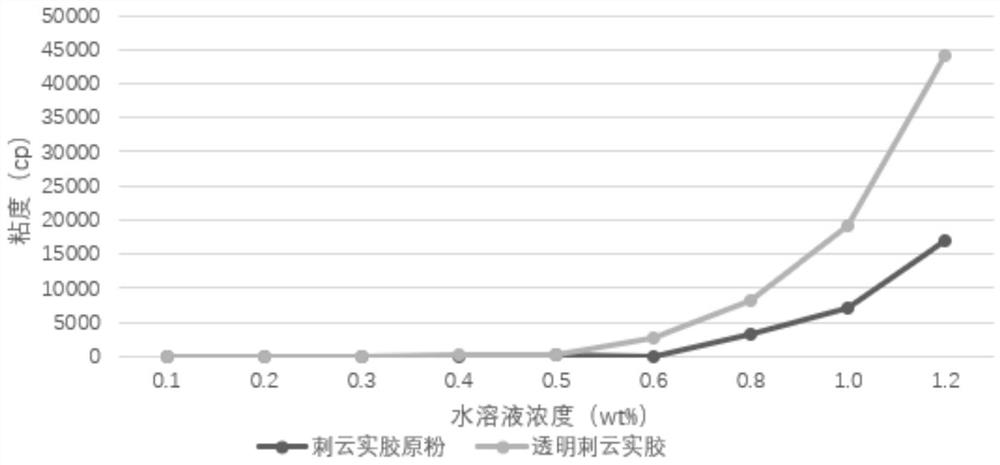

A thorn cloud solid glue and transparent technology, which is applied in the field of high transparent thorn cloud solid glue and its preparation field, can solve the problem of limiting the application range and application value of thorn cloud solid glue, and the quality characteristics of high transparent thorn cloud solid glue are not clear. , does not involve the application of high-transparency type thorn cloud solid glue and other issues, to achieve the effect of being suitable for large-scale promotion and application, unique application value, and improving comprehensive nursing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] The application proposes a preparation method of highly transparent tara gum, comprising the following steps:

[0062] (1) commercially available tara gum solid powder is placed in water to keep warm and fully swell, stir, disperse, and dissolve into a milky white solution;

[0063] (2) heating the milky white solution to adjust the pH value of the milky white solution, and then adding protease to the above milky white solution for enzymolysis to obtain an enzymolysis feed liquid;

[0064] (3) adjusting the pH value of the above-mentioned enzymatic hydrolysis feed liquid, heating the enzymatic hydrolysis feed liquid and then insulated to inactivate the enzyme, so as to obtain the enzymatic hydrolysis feed liquid;

[0065] (4) Carrying out column adsorption filtration to the above-mentioned enzyme-killing liquid to obtain the filtrate;

[0066] (5) The above-mentioned filtrate is subjected to fine filtration, and the pH value of the fine filtrate is adjusted to obtain a...

preparation example 1

[0112] A kind of highly transparent tara gum, comprising the following preparation steps:

[0113] (1) swelling and dissolution:

[0114] Get 5 kilograms of commercially available tara gum solid powder and place in 1000 liters of extraction tanks, quantitatively add pure water in 1000 liters of extraction tanks, the addition weight of pure water is 100 times of the tara gum feeding weight, i.e. 500 kilograms, Start stirring, heat up to 60°C, keep warm, swell, stir, disperse, and dissolve into a milky white solution.

[0115] (2) Enzymolysis:

[0116] The above-mentioned dissolving qualified tara gum solution is heated up to 60°C, and the pH value of the tara gum solution is adjusted with 5% dilute sodium hydroxide aqueous solution: 7.0, and the tara gum solution is added to the tara gum solution for feeding. 0.5% by weight of neutral protease, heat preservation and extraction for 4 hours to obtain enzymatic hydrolysis material liquid.

[0117] (3) pH adjustment, enzyme inac...

Embodiment 1

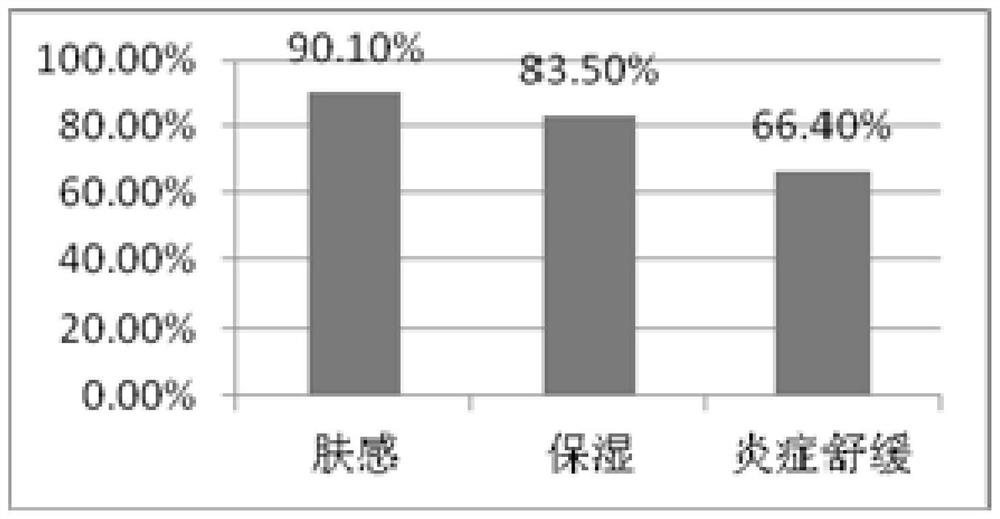

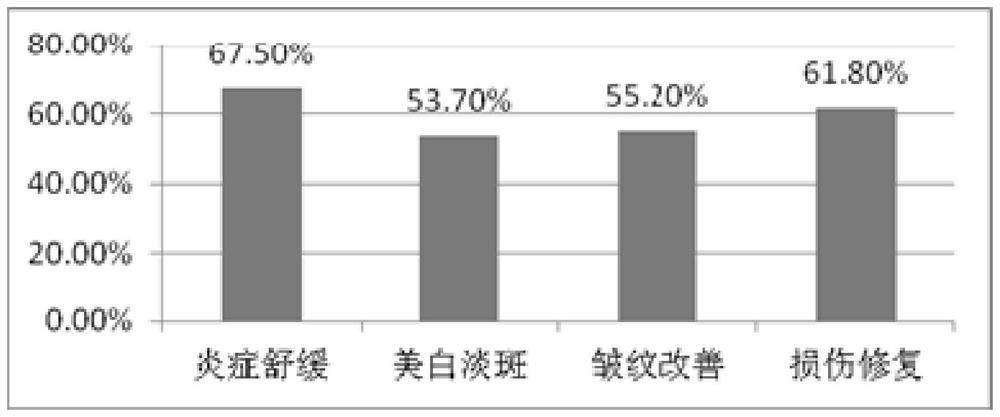

[0126] A highly transparent tara gum product for cosmetics without preservatives, comprising the following preparation steps:

[0127] (1) Preparation: add p-anisic acid in the tara gum concentrated solution obtained in Preparation Example 1, the addition of p-anisic acid is 0.05% by weight of the concentrated solution, i.e. 0.125 kg, and add propylene glycol in the concentrated solution simultaneously , the addition of propylene glycol is 5% by weight of the concentrated solution, i.e. 12.5 kilograms;

[0128] (2) Sterilization: After the preparation solution is stirred evenly, heat up to 80° C., heat preservation and sterilization for 30 minutes to obtain a sterilizing solution;

[0129] (3) Fine filtration: the sterilizing solution is passed through a 0.2 μm filter element to obtain a clear and transparent solution, which is prepared into a highly transparent tara gum product for cosmetics without preservatives.

[0130] The characteristic quality index of highly transpare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com